Ether-ester copolymerized polycarboxylic acid water reducer and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of concrete admixtures, can solve problems such as affecting project quality, strong adaptability, and sensitivity to water addition, and achieves the effects of wide adaptability, strong adaptability and good adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

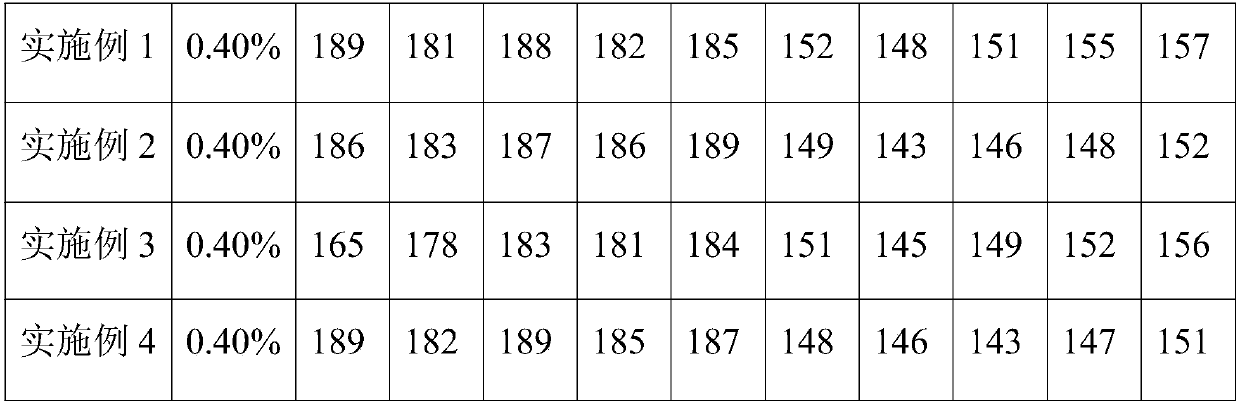

Embodiment 1

[0023] Add 300g water, 200g methacryl alcohol polyoxyethylene ether (HPEG2400), 100g methoxypolyoxyethylene ether methacrylate (MPEG1000), 10.0g maleic anhydride and 2.0g hydrogen peroxide in a 1000m1 round bottom three-neck flask as Reaction solution.

[0024] Prepare solution A: mix 18.0g acrylic acid, 1.5g acrylamide, 1.5g mercaptopropionic acid and 40g water and put them in the dropping funnel.

[0025] Preparation of solution B: mix 0.5g of vitamin C and 60g of water and put them in the dropping funnel.

[0026] Stir until the monomers in the flask are dissolved, and raise the temperature to 60°C. Immediately start adding liquid A and liquid B dropwise at the same time. Solution A will be dropped at the same time in 3.0 hours, and solution B will be dropped in 3.5 hours. After continuing to keep warm for 1 hour, add 7.5g32 % sodium hydroxide solution, adjust the pH value of the solution to 6-7, and replenish water to obtain a 40% ether-ester copolymerized polycarboxylate...

Embodiment 2

[0028] Add 300g water, 150g methacryl alcohol polyoxyethylene ether (HPEG2400), 150g methoxypolyoxyethylene ether methacrylate (MPEG1200), 12g maleic anhydride and as reaction bottom liquid in 1000ml round bottom three-neck flask, 2.0g ammonium persulfate and 1.0g hydrogen peroxide.

[0029] Preparation of solution A: Mix 15g of acrylic acid, 3.0g of 2-acrylamide-2-methylpropanesulfonic acid (AMPS), 2.0g of mercaptopropionic acid and 30g of water and put them in the dropping funnel.

[0030] Preparation of solution B: mix 0.8g of Diaobai Kuai and 60g of water and put them in the dropping bottle.

[0031] Stir until the monomers in the flask are dissolved, and raise the temperature to 40°C. Immediately start adding liquid A and liquid B dropwise at the same time. Liquid A drops in 3.0 hours, and liquid B drops in 3.5 hours. After continuing the heat preservation reaction for 1 hour, add 8.0g of 32% sodium hydroxide solution, adjust the pH value of the solution to 6-7, and repl...

Embodiment 3

[0033] Add 300g of water, 180g of isopentenol polyoxyethylene ether (TPEG2400), 120g of methoxypolyoxyethylene ether methacrylate (MPEG1000), 12g of fumaric acid, and 3.0g of ammonium persulfate into a 1000ml round-bottomed three-neck flask as a reaction solution.

[0034] Prepare solution A: mix 18g itaconic acid, 3g N-N dimethylacrylamide, 1.5g mercaptopropionic acid and 40g water and put them in the dropping funnel.

[0035] Preparation of solution B: mix 0.2g of Diaobai Kuai, 0.4g of vitamin C and 60g of water and put them in the funnel of the dropping bottle.

[0036] Stir until the monomers in the flask are dissolved, and raise the temperature to 50°C. Immediately start adding liquid A and liquid B dropwise at the same time. Liquid A drops in 3.0 hours, and liquid B drops in 3.5 hours. After continuing the heat preservation reaction for 1 hour, add 8.0g of 32% sodium hydroxide solution, adjust the pH value of the solution to 6-7, and replenish water to obtain a 40% ethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com