High-performance NiCoCrFeMnTi system high-entropy alloy and preparation method thereof

A high-entropy alloy and high-performance technology, which is applied in the field of high-performance NiCoCrFeMnTi high-entropy alloy and its preparation, can solve the problems of difficult control of alloy composition, low hardness, uneven ingot composition, etc., and achieve high hardness and strength, good The effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

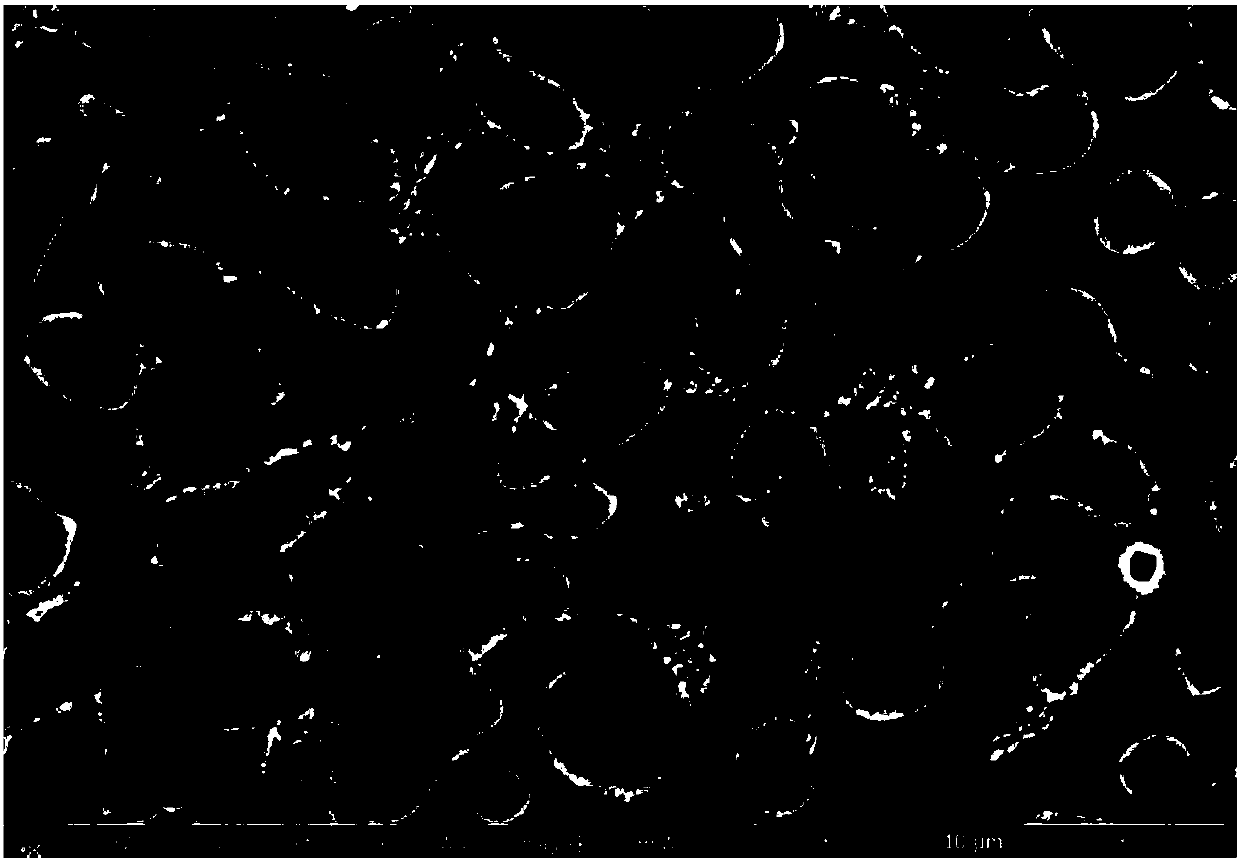

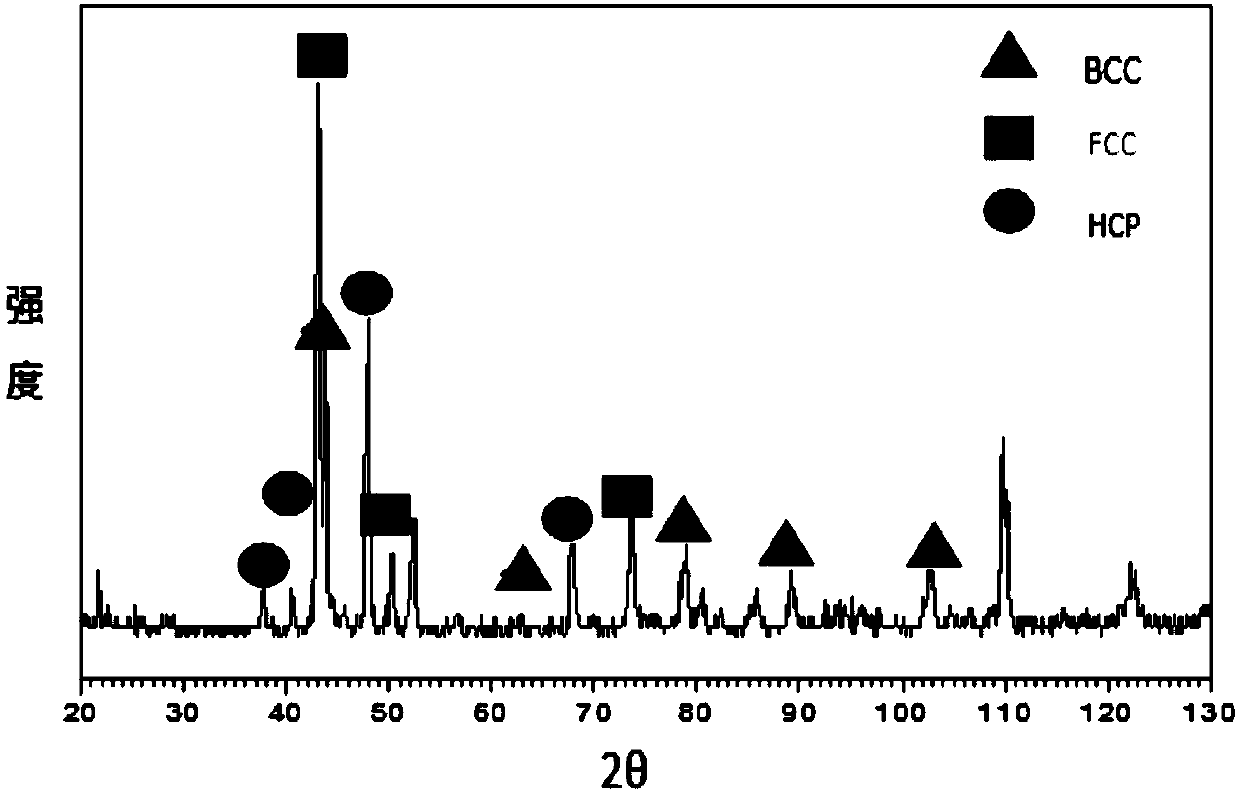

[0034] An ultra-high strength, high wear resistance and high temperature resistant NiCoCrFeMnTi high-entropy alloy of the present invention, the NiCoCrFeMnTi high-entropy alloy includes the following components in atomic percentage: Ni 13%, Co 13%, Cr 13%, Fe 13% , Mn 13%, Ti 35%; the chemical formula of the NiCoCrFeMnTi high-entropy alloy is Ni 13 co 13 Cr 13 Fe 13 mn 13 Ti 35 .

[0035] A method for preparing the NiCoCrFeMnTi system high-entropy alloy of the present embodiment, comprising the following steps:

[0036] (1) Select pure metal sources containing Ni, Co, Cr, Fe, Mn, Ti elements, and prepare materials according to the atomic percentage of the required alloy; (2) Carry out multiple vacuum exhaust treatments on the melting furnace and then fill it with inert gas (3) Under the protection of an inert gas, the raw materials containing Fe, Ni, Co, Cr, Mn, Ti elements are subjected to argon arc melting in a smelting furnace: firstly add pure elements containing Ni,...

Embodiment 2

[0039] An ultra-high strength, high wear resistance and high temperature resistant NiCoCrFeMnTi high-entropy alloy of the present invention, the NiCoCrFeMnTi high-entropy alloy includes the following components in atomic percentage: Ni 19%, Co 19%, Cr 19%, Fe 19% , Mn 19%, Ti 5%; the chemical formula of the NiCoCrFeMnTi high-entropy alloy is Ni 19 co 19 Cr 19 Fe 19 mn 19 Ti 5 .

[0040] A method for preparing the NiCoCrFeMnTi system high-entropy alloy of the present embodiment, comprising the following steps:

[0041] (1) Select a pure metal source containing Ni, Cr, Fe, Ti elements, and an intermediate alloy containing Co, Mn elements, and prepare materials according to the atomic percentage of the required alloy; (2) Perform multiple vacuum exhausts on the melting furnace Process to maintain vacuum, the vacuum degree is greater than 10 -3 Pa; (3) Under vacuum conditions, the raw materials containing Ni, Co, Cr, Fe, Mn, Ti elements are subjected to vacuum induction sme...

Embodiment 3

[0044] An ultra-high-strength, high-wear, high-temperature resistant NiCoCrFeMnTi-based high-entropy alloy of the present invention, the NiCoCrFeMnTi-based high-entropy alloy includes the following components in atomic percentage: Ni 18%, Co 18%, Cr 18%, Fe 18% , Mn 11.4%, Ti 16.6%; the chemical formula of the NiCoCrFeMnTi high-entropy alloy is Ni 18 co 18 Cr 18 Fe 18 mn 11.4 Ti 16.6 .

[0045] A method for preparing the NiCoCrFeMnTi system high-entropy alloy of the present embodiment, comprising the following steps:

[0046](1) Select pure metal sources containing Ni, Co, Cr, Fe, Mn, Ti elements, and prepare materials according to the atomic percentage of the required alloy; (2) Carry out multiple vacuum exhaust treatments on the melting furnace and then fill it with inert gas (3) Under the protection of an inert gas, the raw materials containing Ni, Co, Cr, Fe, Mn, Ti elements are subjected to argon arc melting in a smelting furnace: firstly add pure elements containin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com