Preparation method for TiN film coated glass

A technology for coating glass and glass, which is applied in the field of preparing TiN-coated glass by ultrasonic atomization and nano-TiN powder, can solve the problems of easy hydrolysis and oxidation, unsuitable for large-scale coating production, danger, etc., and improve the appearance and performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with embodiments and drawings, but the present invention is not limited to this.

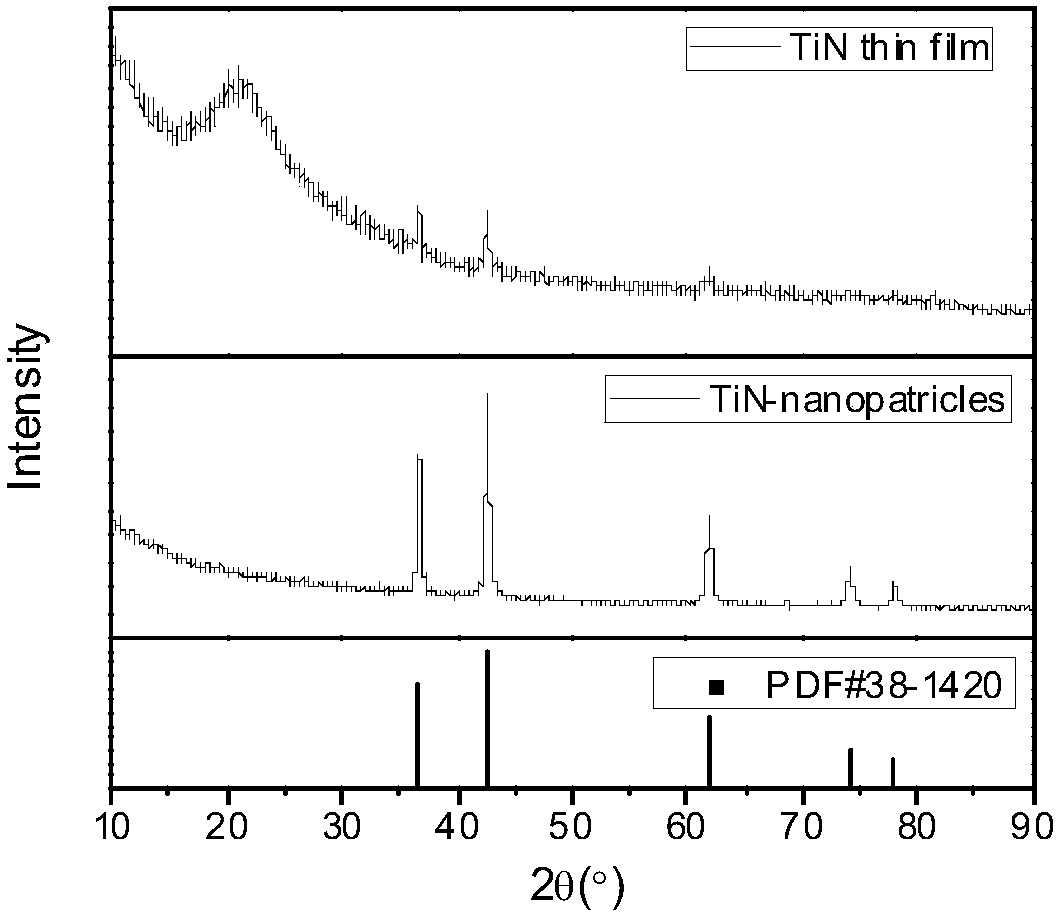

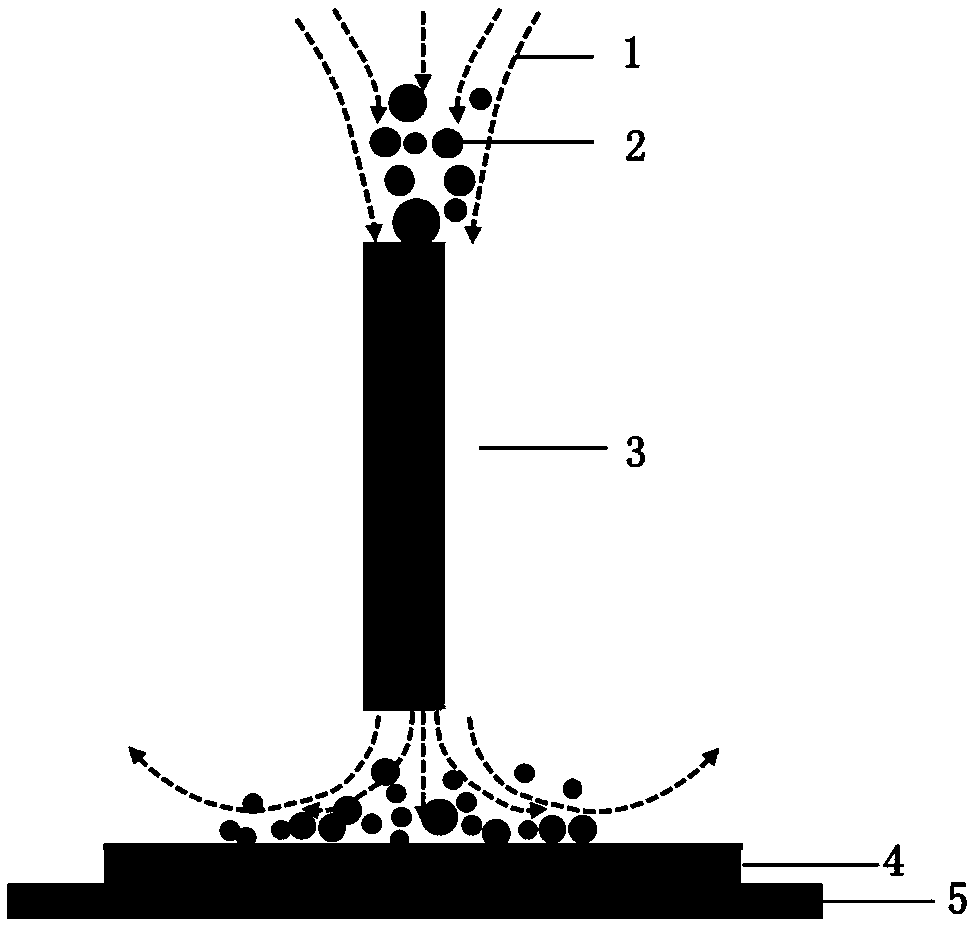

[0024] Such as figure 1 with figure 2 As shown, the steps for preparing TiN coated glass in this embodiment are as follows:

[0025] (1) Ultrasonic cleaning the quartz plate (glass substrate) with surfactant, ethanol, and water for 30 minutes, and vacuum drying at 80°C;

[0026] (2) Dissolve 309.4 mg of TiN powder in 100 mL of ethanol aqueous solution with a volume ratio of 1:1, and configure it to a concentration of 0.05 mol·L -1 Use an ultrasonic pulverizer to treat the suspension for 30 minutes to obtain a uniformly dispersed TiN precursor;

[0027] (3) Open the heating platform 5, place the cleaned quartz plate (namely the glass substrate 4) on the platform, raise the temperature to 240°C, measure the temperature of the substrate with a temperature gun, and control the temperature change within the range of ±5°C;

[0028] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com