Food contact resealing label material, food contact resealing label, preparation method of materials and application of materials

A food contact and labeling material technology, applied in the direction of seal, adhesive type, film/sheet adhesive, etc., can solve the problems of food aroma, nutrient loss, food waste, throwing away, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] A preparation method for food contact resealing label material, comprising

[0066] Preparation of acrylic pressure-sensitive adhesive step;

[0067] Infrared radiation drying step: transfer the above-mentioned silicone oil backing paper / film after coating the adhesive to the far-infrared radiation area, use far-infrared radiation to penetrate the acrylic two-liquid cross-linked pressure-sensitive adhesive, and then enter the drying tunnel , the drying tunnel is provided with a baking area with gradually increasing temperature, and hot air drying is carried out through the baking area;

[0068] The step of compounding the adhesive with the film base material: the above-mentioned acrylic two-liquid cross-linked pressure-sensitive adhesive that has been dried and cured by far-infrared radiation is transferred to a film with an oxygen permeability lower than 2.0×10 -5 m 3 / m 2 ·d·Pa, moisture permeability lower than 2.0×10 -4 kg(s·m 2 ) on the film substrate.

[0069...

Embodiment 1

[0099] A food contact resealable label material comprising:

[0100] The oxygen permeability rate is 1.15×10 -5 m 3 / m 2 ·d·Pa, moisture permeability is 1.44×10 -4 kg(s·m 2 ) film base material, the film base material is a polyethylene film of vapor-deposited aluminum;

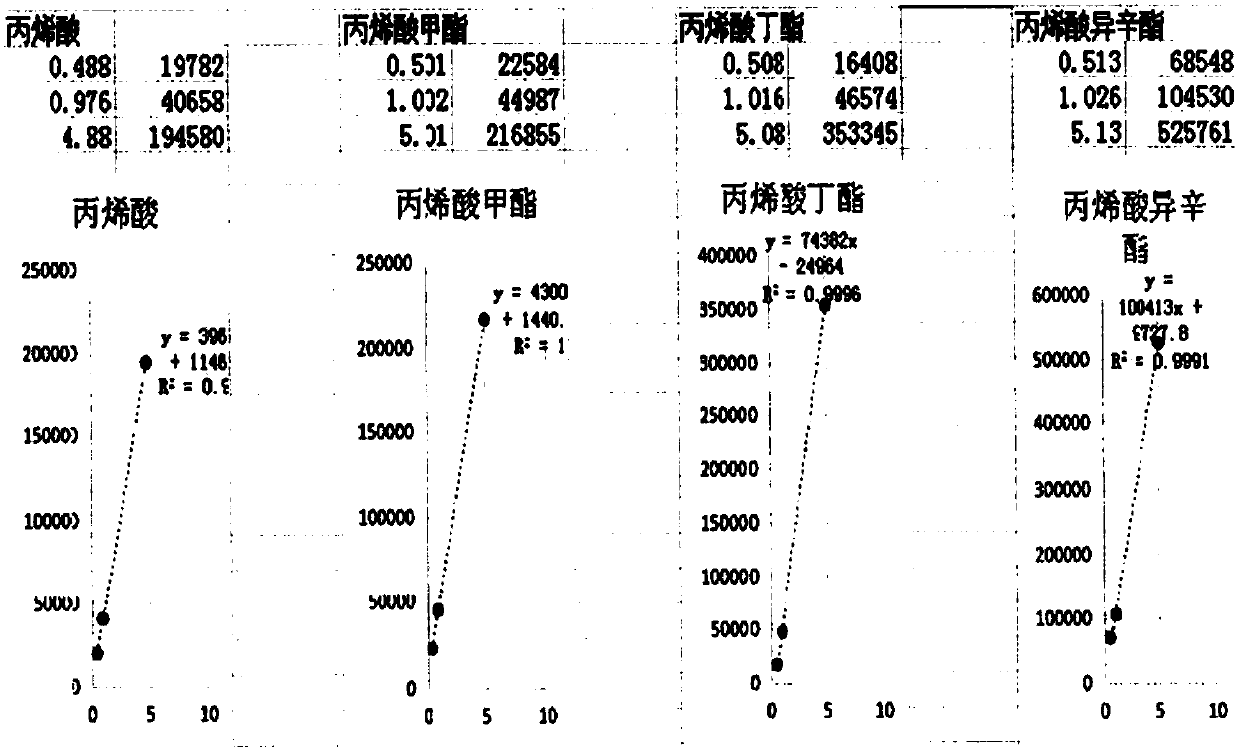

[0101] an acrylic pressure sensitive adhesive disposed on the lower surface of the film substrate, the acrylic pressure sensitive adhesive being a food contact resealing solvent comprising an acrylic monomer as one liquid and an isocyanate crosslinking agent as two liquids Type acrylic acid two-liquid crosslinking pressure-sensitive adhesive, in parts by weight is respectively:

[0102] Acrylic acid 10 parts;

[0103] Butyl acrylate 15 parts

[0104] 5 parts methyl acrylate

[0105] 1 part of cyclohexyl isocyanate;

[0106]0.5 parts of azobisisobutyronitrile;

[0107] 70 parts of acetone;

[0108] a silicone liner / film disposed on the lower surface of the acrylic pressure sensitive adhesive;

[010...

Embodiment 2

[0115] A food contact resealable label material comprising:

[0116] The oxygen permeability rate is 1.10×10 -5 m 3 / m 2 ·d·Pa, moisture permeability is 1.46×10 -4 kg(s·m 2 ), the film substrate is a polyester film coated with PVDC;

[0117] an acrylic pressure sensitive adhesive disposed on the lower surface of the film substrate, the acrylic pressure sensitive adhesive being a food contact resealing solvent comprising an acrylic monomer as one liquid and an isocyanate crosslinking agent as two liquids Type acrylic acid two-liquid crosslinking pressure-sensitive adhesive, in parts by weight is respectively:

[0118] 3 parts acrylic

[0119] 17 parts of isooctyl acrylate

[0120] Propyl acrylate 5 parts

[0121] 10 parts of methyl acrylate;

[0122] Butylene oxide 1 part

[0123] 0.5 parts of diphenylmethane-4,4'-diisocyanate;

[0124] 0.4 parts of azobisisoheptanonitrile;

[0125] 65 parts of isopropanol;

[0126] a silicone liner / film disposed on the lower surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com