Genetically engineered bacteria and application thereof in production of BT (D-1,2,4-butanetriol)

A genetically engineered bacteria and gene technology, applied to genetically engineered bacteria and its application in the production of D-1,2,4-butanetriol, can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

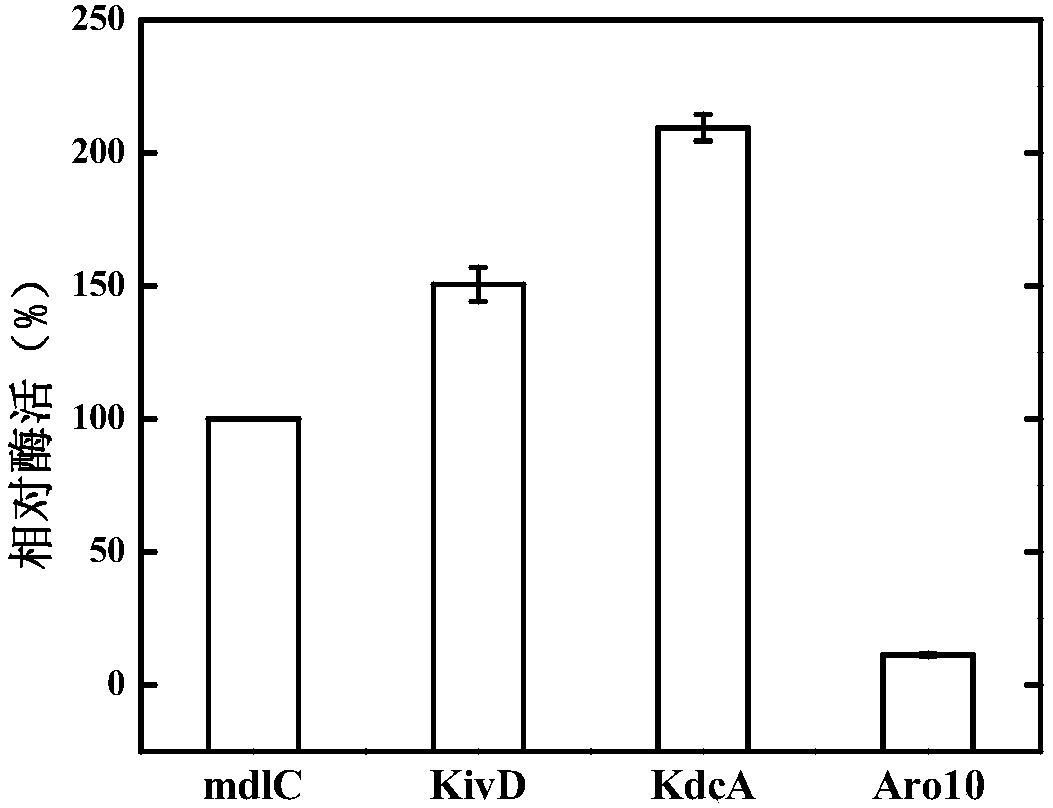

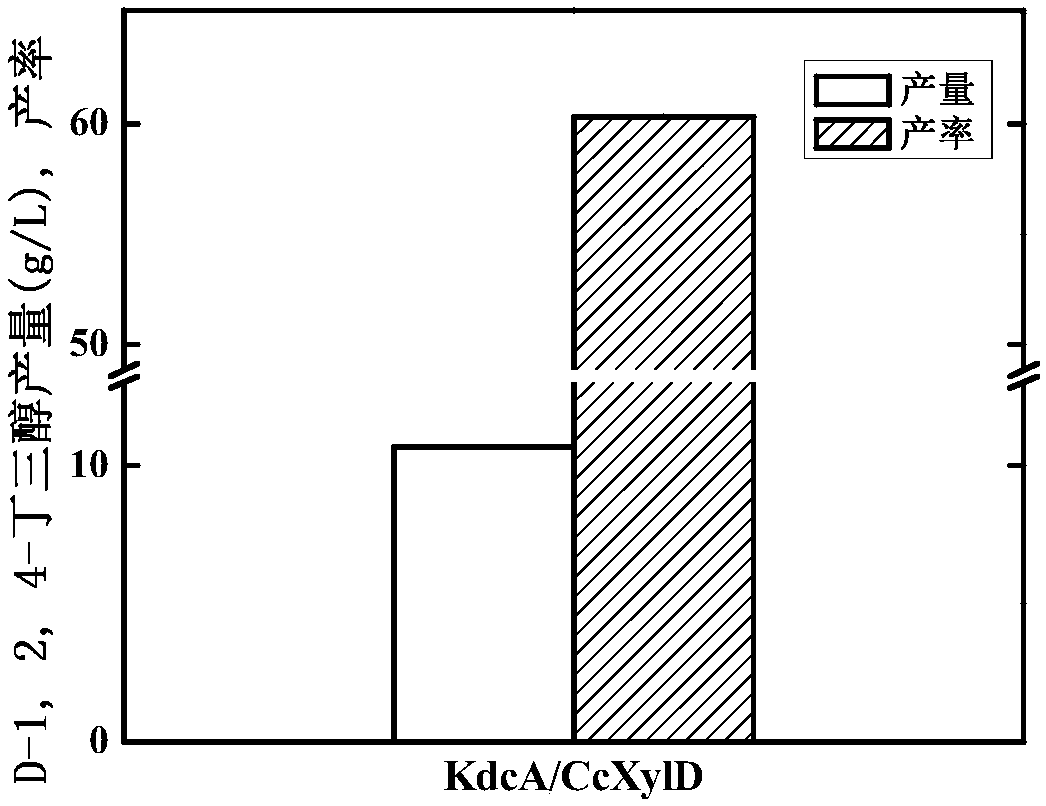

[0036] Example 1 Construction of genetically engineered bacteria BL21-02, BL21-08, BL21-09, BL21-10

[0037] 1) Construct clones expressing 2-ketoacid decarboxylase genes MdlC, KivD, KdcA, Aro10; xylose dehydrogenase gene XylB, D-xylose dehydratase YjhG and alcohol dehydrogenase gene YqhD; D-xylose dehydration Enzyme YjhG ( Escherichia coli ), GeneID: 946829; the xylose dehydrogenase gene XylB, Gene ID: 7329904; the alcohol dehydrogenase gene YqhD, GenBank: ADK47404.1; the α-keto acid decarboxylase ( Lactococcus lactis ), GenBank: AAS49166.1;

[0038] 2) The 2-ketoacid decarboxylase genes MdlC, KivD, KdcA, and Aro10 were respectively inserted into the plasmid pTRC99a (TransGen) Nco I and Sac Between the Ⅰ sites, the plasmids pTRC-MdlC, pTRC-KivD, pTRC-KdcA, pTRC-Aro10 were obtained, and the XylB gene was inserted into the plasmid pTRC99a Nco I and Bam Between the HI sites, pTRC99a-XylB was obtained. Then the XylB fragment with the TRC promoter was obtained by PCR, ...

Embodiment 2

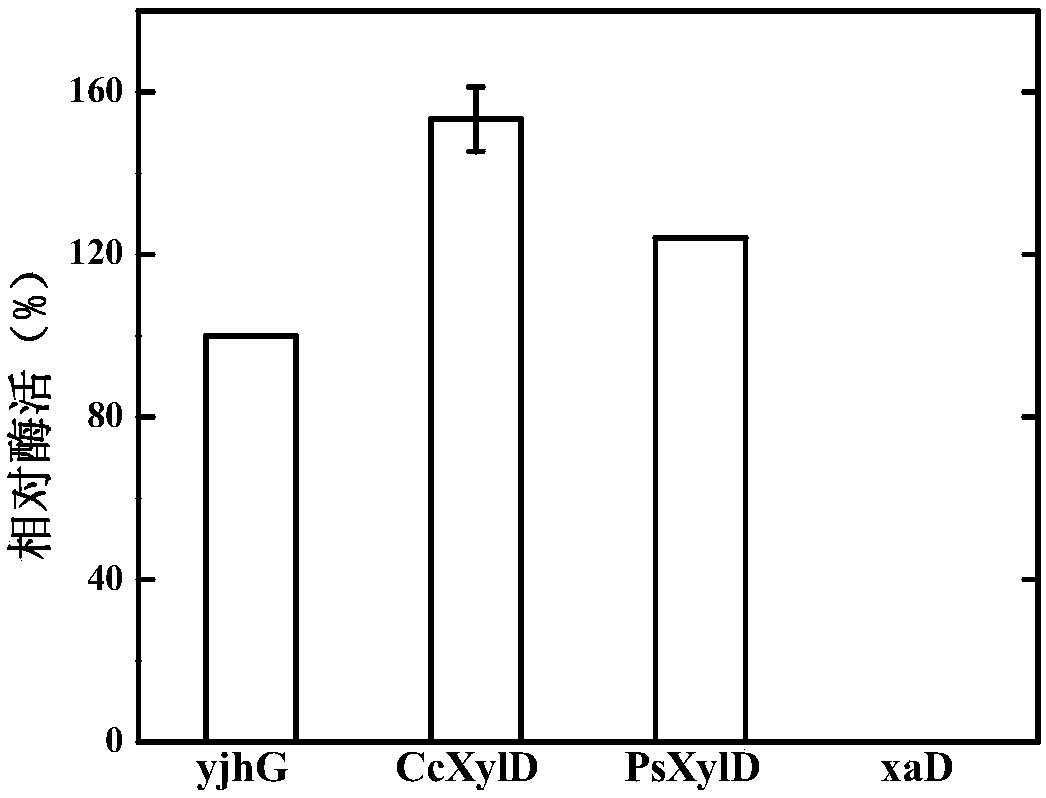

[0041] The construction of embodiment 2 genetically engineered bacteria BL21-11, BL21-12, BL21-13

[0042] 1) Construct clones expressing benzoylformate decarboxylase gene MdlC and xylose dehydrogenase gene XylB, xylose dehydratase genes CcXylD, PsXylD, HvXylD and alcohol dehydrogenase gene YqhD.

[0043] 2) The MdlC gene was inserted into the plasmid pTRC99a Nco I and Sac Between the Ⅰ sites, the plasmid pTRC-MdlC was obtained, and the XylB gene was inserted into the plasmid pTRC99a Nco I and Bam Between the HI sites, pTRC99a-XylB was obtained. Then obtain the XylB fragment with the TRC promoter by PCR, insert the fragment into the plasmid pTRC-MdlC Sac I and Bam Between the H I sites, the plasmid pTRC-MdlC-TRC-XylB was obtained.

[0044] 3) The gene fragments CcXylD, PsXylD, HvXylD, and YqhD were respectively inserted into the pCWJ plasmids to obtain recombinant plasmids pCWJ-CcXylD, pCWJ-PsXylD, pCWJ-HvXylD, and pCWJ-YqhD. Using the pCWJ-YqhD plasmid as a templ...

Embodiment 3

[0046] Example 3 Fermentation of genetically engineered bacteria BL21-02, BL21-08, BL21-09, BL21-10 to produce D-1,2,4-butanetriol

[0047] Plate culture:

[0048] Take out the glycerin frozen bacteria stored at -80°C, and put them on the plate medium (peptone 10g / L, yeast powder 5g / L, NaCl10 g / L, ampicillin 100 mg / L, chloramphenicol 68 mg / L) Streak operation was performed on the plate, and then the plate was placed in a 37°C incubator for 12-16h.

[0049] Seed liquid culture:

[0050] Add 5 mL of seed medium (peptone 10g / L, yeast powder 5g / L, NaCl 10 g / L, ampicillin 100 mg / L, chloramphenicol 68 mg / L) into a 50 mL centrifuge tube, pick a small amount Glycerol-frozen bacteria were inoculated and cultured at 200 rpm and 37 °C for 10-12 h.

[0051] Shake flask fermentation culture:

[0052] 50 mL of fermentation medium (10 g / L peptone, 5 g / L yeast powder, 10 g / L NaCl, 25 g / L D-xylose, 100 mg / L ampicillin, chloramphenicol 68 mg / L), the inoculum size was 1%, the rotation speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com