Scandium doped terbium aluminum garnet magneto-optical crystal and preparation method thereof

A magneto-optic crystal and garnet technology, which is applied in the field of scandium-doped terbium aluminum garnet magneto-optic crystal and its preparation, can solve the problems of crystal cracking and unusability, achieve short cycle time, good thermal performance, and realize large-scale low-cost The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

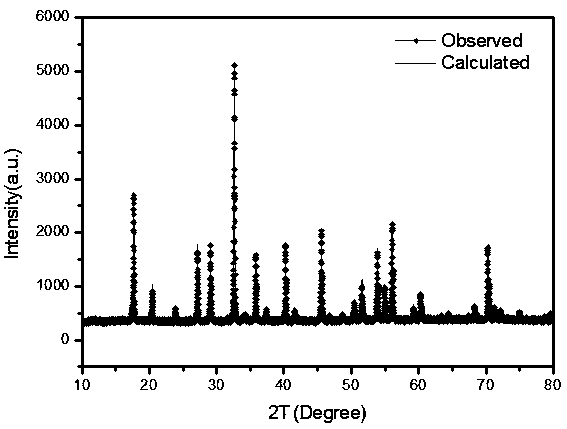

[0028] Growth of Tb by Guided Mode Pulling 3 sc 1.0 Al 4.0 o 12 crystals.

[0029] 1) Press Tb 3 sc 1.0 Al 4.0 o 12 The stoichiometric ratio accurately weighs Tb 4 o 7 (99.99%), Sc 2 o 3 (99.999%), Al 2 o 3 (99.99%) The raw materials are put into a corundum mortar, mixed and ground evenly. After being pressed into tablets, they are placed in a muffle furnace for high-temperature sintering to prepare high-purity polycrystalline raw materials; for 17 hours.

[0030] 2) The size is about φ60×40 mm 3 The iridium gold crucible is used as the container for crystal growth, and the iridium gold module with holes is the guided mode module. The synthesized polycrystalline powder raw materials were put into the iridium crucible of the single crystal pulling furnace, and the single crystal guided mode pulling growth was carried out under the Ar atmosphere. The growth temperature was 1900°C, and the axial temperature gradient near the growth interface was 27±3°C / cm, the gr...

Embodiment 2

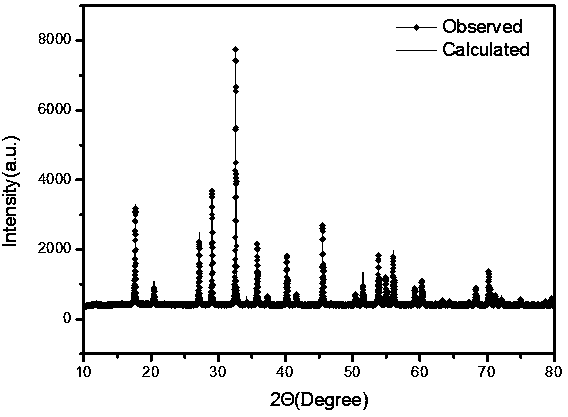

[0033] Growth of Tb by pulling method 3 sc 1.3 Al 3.7 o 12 crystals.

[0034] 1) Press Tb 3 sc 1.3 Al 3.7 o 12 The stoichiometric ratio accurately weighs Tb 4 o 7 (99.99%), Sc 2 o 3 (99.999%), Al 2 o 3 (99.99%) raw materials, the raw materials are put into a corundum mortar, mixed and ground evenly, after being pressed into tablets, placed in a muffle furnace for high-temperature sintering for 15 hours to prepare high-purity polycrystalline raw materials; the high-temperature sintered The temperature is 1500°C;

[0035] 2) The size is about φ60×40 mm 3 The iridium crucible is used as the container for crystal growth. Put the synthesized polycrystalline powder raw materials into the iridium crucible of the single crystal pulling furnace, and carry out single crystal growth under Ar atmosphere. The growth temperature is 1870 ° C, near the growth interface. The axial temperature gradient of the crystal is 20±3°C / cm, the growth rate is about 2.0 mm / h, and the cryst...

Embodiment 3

[0038] Tb 3 sc 1.5 Al 3.5 o 12 The preparation of crystal comprises the following steps:

[0039] 1) Press Tb 3 sc 1.5 Al 3.5 o 12 The stoichiometric ratio accurately weighs Tb 4 o 7 (99.99%), Sc 2 o 3 (99.999%), Al 2 o 3 (99.99%) raw materials, the raw materials are put into the corundum mortar and mixed, ground evenly, after being pressed into tablets, placed in the muffle furnace and carried out high-temperature sintering for 15 hours to prepare high-purity polycrystalline raw materials; the temperature of high-temperature sintering is 1400°C.

[0040] 2) The size is about φ60×40 mm 3 The iridium crucible is used as the container for crystal growth, put the synthesized polycrystalline powder raw material into the iridium crucible of the single crystal pulling furnace, and carry out single crystal growth under Ar atmosphere, the growth temperature is 1850 ℃, near the growth interface The axial temperature gradient is 13±3°C / cm, the growth rate is about 1.0 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com