Method for preparing PLGA microspheres

A PLGA and microsphere technology, applied in the field of medicine, can solve the problems of increasing the viscosity of the solution, and achieve the effect of easy dispersion and difficult aggregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

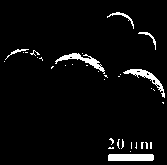

[0052] Example 1 Using hydrophilic nanocellulose as an emulsifier to prepare fat-soluble drug blank drug-loaded PLGA microspheres:

[0053] 1) Dispersing hydrophilic nanocellulose in water, and dissolving a certain amount of sodium chloride or other ionic solutes as the aqueous phase A of the emulsion;

[0054] 2) Dissolving PLGA (molecular weight 20000, lactic acid: glycolic acid molar ratio = 1:1) in the oil phase solvent as the oil phase B of the emulsion;

[0055] 3) Mix the above water phase A and oil phase B, ultrasonically prepare O / W emulsion, remove the water phase and oil phase solvent,

[0056] After washing, filtering, and freeze-drying, the PLGA microspheres can be obtained.

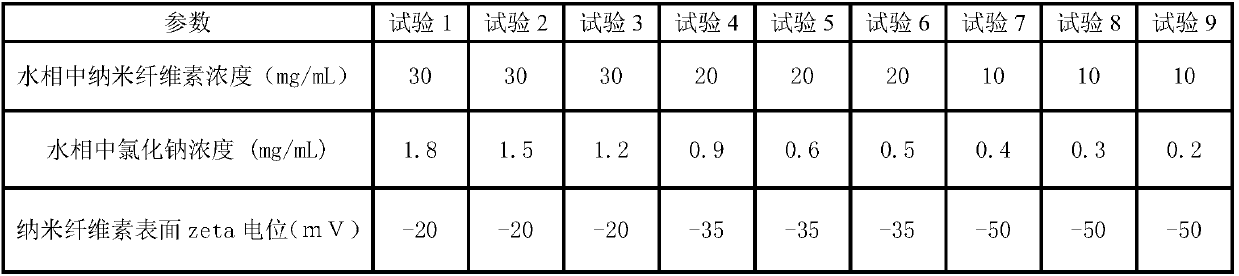

[0057] The test results under each test parameter are listed as follows:

[0058]

[0059] .

[0060] According to experiments 1 to 9, the following conclusions can be drawn:

[0061] The diameter of PLGA microspheres is closely related to the concentration of NaCl in the aqueous ph...

Embodiment 2

[0065] The steps for preparing hydrophilic drug blank drug-loaded PLGA microspheres with hydrophilic nanocellulose are as follows:

[0066] 1) Dissolve PLGA (molecular weight 25000, lactic acid: glycolic acid molar ratio = 1:3) and W / O emulsion stabilizer span60 in the oil phase solvent, which is oil phase A;

[0067] 2) Purified water is used as the water phase B;

[0068] 3) Mix the above oil phase A and water phase B, and ultrasonically prepare W / O type colostrum C;

[0069] 4) Disperse the hydrophilic nanocellulose in water, and dissolve sodium chloride as the aqueous phase D of the emulsion;

[0070] 5) Colostrum C is mixed with water phase D, and ultrasonically prepared to prepare W / O / W double emulsion type emulsion. After removing the water phase and oil phase solvent,

[0071] After washing, filtering, and freeze-drying, the PLGA microspheres can be obtained.

[0072] The test results under each test parameter are listed as follows:

[0073]

[0074] .

[007...

Embodiment 3

[0081] Example 3 Preparation of O / W type PLGA microspheres with risperidone as model drug

[0082] 1) Disperse the hydrophilic nanocellulose in water, and dissolve a certain amount of sodium chloride as the aqueous phase A of the emulsion;

[0083] 2) Dissolving PLGA (molecular weight 25000, lactic acid: glycolic acid molar ratio = 1:1), risperidone raw material in the oil phase solvent dichloromethane as the oil phase B of the emulsion;

[0084] 3) Mix the above water phase A and oil phase B, ultrasonically prepare O / W emulsion, remove the water phase and oil phase solvent, wash,

[0085] PLGA microspheres can be obtained by freeze-drying.

[0086] The test results under each test parameter are listed as follows:

[0087] .

[0088] As can be seen from the above table, the above six groups of test parameters can be prepared by the above method to obtain risperidone PLGA drug-loaded microspheres.

[0089] Its diameter decreases with increasing sodium chloride concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Electric potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com