Method for preparing monothiocarbonate

A technology of propylene monothiocarbonate and carbon oxysulfide, which is applied in the field of fine synthesis of compounds, can solve problems such as unreported industrial production methods of propylene monothiocarbonate, and achieve high atom utilization, simple process, and The effect of green environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

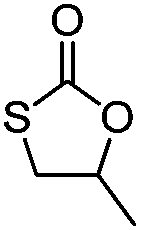

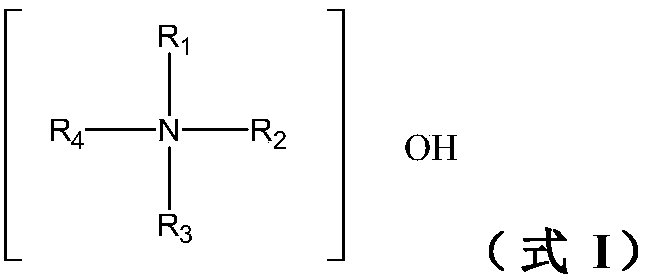

[0029] The invention provides a method for preparing propylene monothiocarbonate, the method comprising: under cycloaddition reaction conditions, contacting propylene oxide and carbon oxysulfide with a catalyst, characterized in that the catalyst includes: Titanium-silicon molecular sieve with template agent and titanium-silicon molecular sieve containing template agent.

[0030] According to the method of the present invention, as long as it is ensured that the catalyzer includes: the titanium-silicon molecular sieve that removes the template agent and the titanium-silicon molecular sieve that contains the template agent can realize the purpose of the present invention, from further improving the conversion rate of propylene oxide and propylene monothiocarbonate From the viewpoint of ester selectivity, preferably, in the catalyst, the weight ratio of the titanium-silicon molecular sieve containing the template agent to the titanium-silicon molecular sieve without the template ...

Embodiment 1

[0072] (1) Preparation of titanium-silicon molecular sieve TS-1 containing template and titanium-silicon molecular sieve TS-1 catalyst without template.

[0073] With reference to Zeolites, 1992, the method preparation described in the 943-950 page of Vol.12 (saving the step of roasting), concrete method is as follows:

[0074] At room temperature (20°C), mix 22.5 grams of tetraethyl orthosilicate with 7.0 grams of tetrapropylammonium hydroxide, add 59.8 grams of distilled water, stir and mix, then hydrolyze at normal pressure and 60°C for 1.0 hour to obtain ortho For the hydrolysis solution of tetraethyl silicate, slowly add a solution consisting of 1.1 g of tetrabutyl titanate and 5.0 g of anhydrous isopropanol under vigorous stirring, and stir the resulting mixture at 75°C for 3 hours to obtain a clear Transparent colloid. This colloid was put into a stainless steel sealed reaction kettle, and placed at a constant temperature at 170°C for 3 days to obtain a mixture of crys...

Embodiment 2

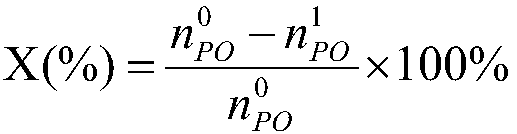

[0079] Use the titanium-silicon molecular sieve containing template agent prepared by embodiment 1 and remove the titanium-silicon molecular sieve of template agent, all the other steps are as follows:

[0080] Propylene oxide, carbon oxysulfide, solvent acetone and catalyzer (in the catalyzer, the mass ratio of the titanium silicon molecular sieve that removes template agent and the titanium silicon molecular sieve that contains template agent is 1:5) according to the molar ratio of propylene oxide and carbon oxysulfide The ratio is 1:2, the mass ratio of the solvent acetone to the catalyst is 120:1, the mass ratio of propylene oxide to the catalyst is 40:1, and the reaction is carried out at a temperature of 50°C and a pressure of 1.5MPa. The results of the reaction for 1 hour were as follows: the conversion rate of propylene oxide was 19%, and the selectivity of propylene monothiocarbonate was 94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial length | aaaaa | aaaaa |

| Benzene adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com