Surface polymerization-modified hydrotalcite material and preparation method thereof

A technology of hydrotalcite and modified water, which is applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve problems such as easy agglomeration, difficult occurrence, poor compatibility, etc. Capacitance, effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step A: Accurately weigh 0.01mol (2.5641g) of Mg(NO 3 ) 2 ·6H 2 O, 0.005mol (1.8756g) of Al(NO 3 ) 3 9H 2 O and 0.05mol (3g) of CO(NH 2 ) 2, dissolved in 80ml deionized water. Using the urea method, the solution was transferred to a polytetrafluoroethylene lining, placed in an oven, and crystallized at 130°C for 24 hours. The product was centrifuged to separate the filter cake and used to remove CO 2 The filtrate was washed with deionized water until pH ≈ 7, and dried for 12 hours. The obtained hydrotalcite precursor was recorded as LDHs.

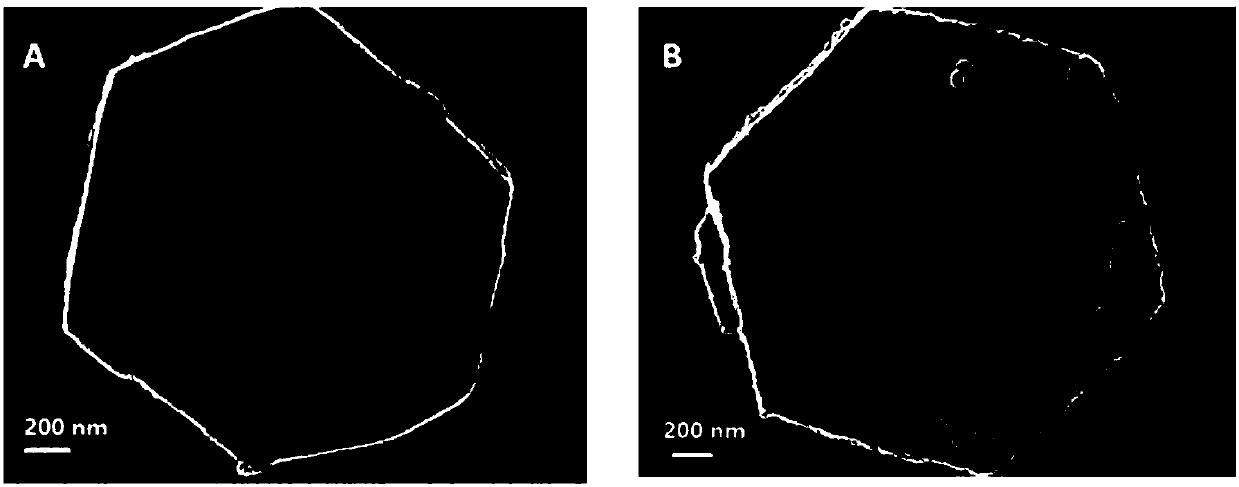

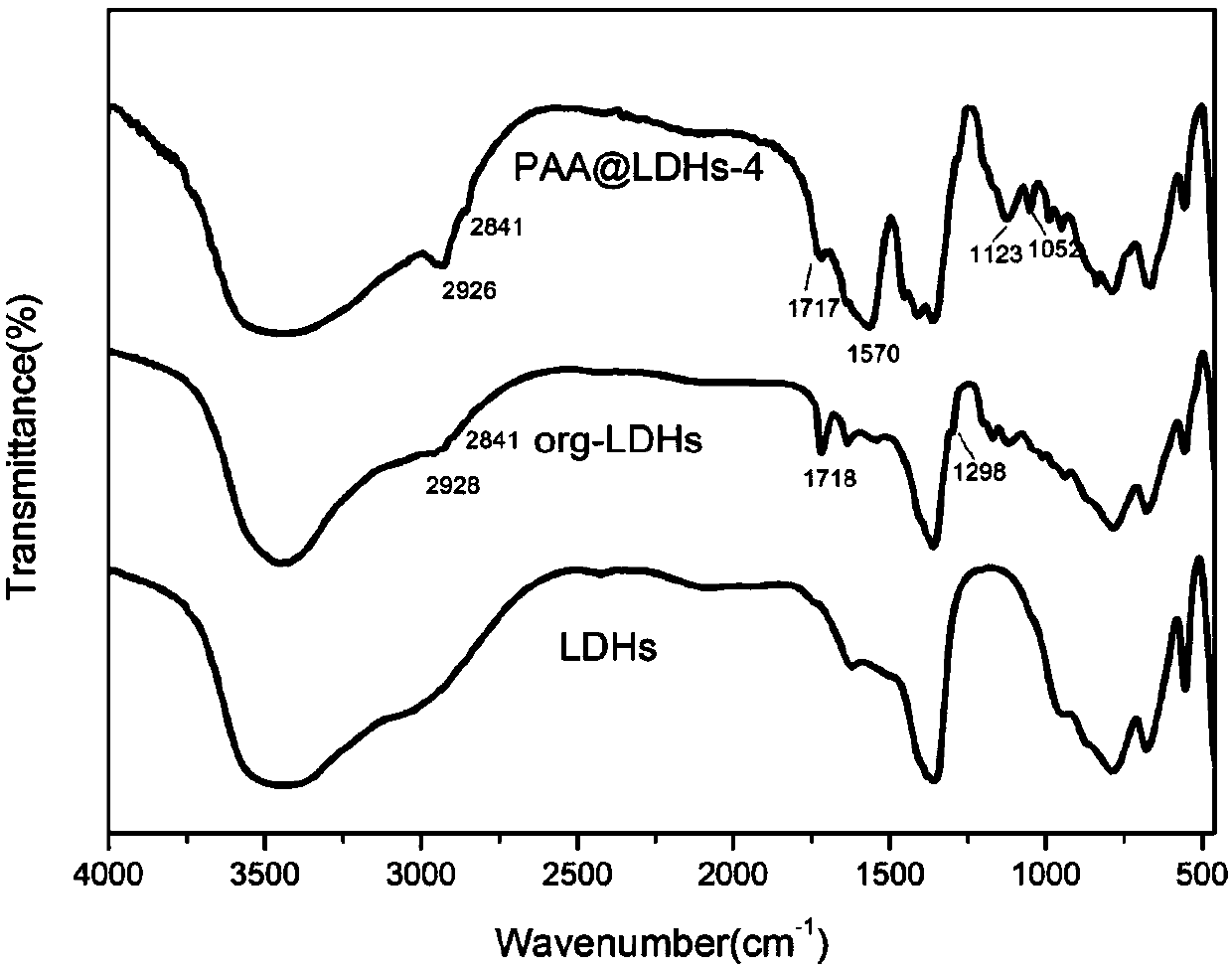

[0031] Step B: Take 3.5g of LDHs precursor powder, add 150ml of cyclohexane, ultrasonicate for 10 minutes, and then transfer to a clean 250ml three-necked bottle. Weigh 0.105g of KH-550 and 0.045g of KH-570, dissolve them in 2ml of cyclohexane, and sonicate for 5 minutes. Under rapid stirring, the above solution was added to the LDHs precursor slurry. Heating to 75°C and reacting for 8 hours to obtain a surface-organized h...

Embodiment 2

[0038] Step A: Accurately weigh 0.01mol (2.5641g) of Mg(NO 3 ) 2 ·6H 2 O, 0.005mol (1.8756g) of Al(NO 3 ) 3 9H 2 O and 0.05mol (3g) of CO(NH 2 ) 2 , dissolved in 80ml deionized water. Using the urea method, the solution was transferred to a polytetrafluoroethylene lining, placed in an oven, and crystallized at 130°C for 24 hours. The product was centrifuged to separate the filter cake and used to remove CO 2 The filtrate was washed with deionized water until pH ≈ 7, and dried for 12 hours. The obtained hydrotalcite precursor was recorded as LDHs.

[0039] Step B: Take 3.5g of LDHs precursor powder, add 150ml of cyclohexane, ultrasonicate for 10 minutes, and then transfer to a clean 250ml three-necked bottle. Weigh 0.105g of KH-550 and 0.045g of KH-570, dissolve them in 2ml of cyclohexane, and sonicate for 5 minutes. Under rapid stirring, the above solution was added to the LDHs precursor slurry. Heating to 75°C and reacting for 8 hours to obtain a surface-organized ...

Embodiment 3

[0042] Step A: Accurately weigh 0.01mol (2.5641g) of Mg(NO 3 ) 2 ·6H 2 O, 0.005mol (1.8756g) of Al(NO 3 ) 3 9H 2 O and 0.05mol (3g) of CO(NH 2 ) 2 , dissolved in 80ml deionized water. Using the urea method, the solution was transferred to a polytetrafluoroethylene lining, placed in an oven, and crystallized at 130°C for 24 hours. The product was centrifuged to separate the filter cake and used to remove CO 2 The filtrate was washed with deionized water until pH ≈ 7, and dried for 12 hours. The obtained hydrotalcite precursor was recorded as LDHs.

[0043] Step B: Take 2g of the precursor powder of LDHs, add 100ml of deionized water and ultrasonic for 10 minutes, then transfer to a clean 250ml four-neck bottle. Under nitrogen protection, weigh 0.4 g of acrylic acid, and add it into the LDHs slurry under rapid stirring. Raise the temperature to 70°C, add 0.1g of cerium ammonium nitrate, and continue the reaction for 12 hours to obtain a surface polymerization-modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com