Polydopamine modified coating facilitating battery heat dissipation

A polydopamine, modified coating technology, applied in secondary batteries, battery electrodes, battery pack components, etc., can solve the problems of exporting battery heat, changing the heat resistance of materials, etc. The effect of adhesion and temperature will not increase significantly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

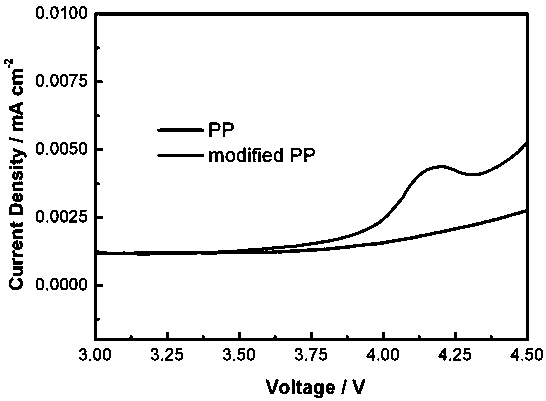

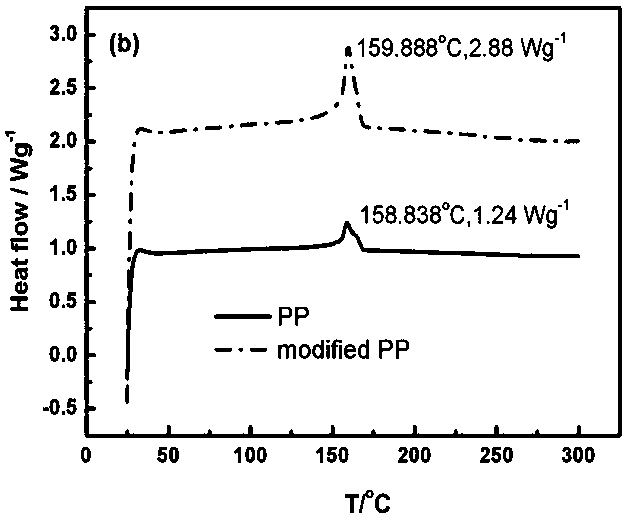

[0019] First, weigh a certain amount of dopamine hydrochloride (189.7 g / mol, Aladdin) and dissolve it in Tris (chemically pure, Aladdin), hydrochloric acid (chemically pure, Sinopharm Shenyang Reagent Factory), methanol (chemically pure, Aladdin), Pure, Sinopharm Shenyang Reagent Factory) and ultrapure water (conductivity less than 18 MΩ -1 ), prepare a dopamine solution with a concentration of 10 mmol / L in a weakly alkaline solution of pH=8.51 configured in a certain proportion. Then, the Celgard PP membrane (Celgard 2500, 25 μm) was immersed in the modified organic material, and taken out after 24 h at room temperature, and rinsed with deionized water for 2 h. Finally, it was dried for 8 h at 50°C in a vacuum environment. Electrochemical window display of polydopamine modified diaphragm ( figure 1 ), the substance can be used in lithium iron phosphate batteries. From figure 2 , 3 According to the TGA and DSC data before and after the diaphragm modification, polydopamine has...

Embodiment 2

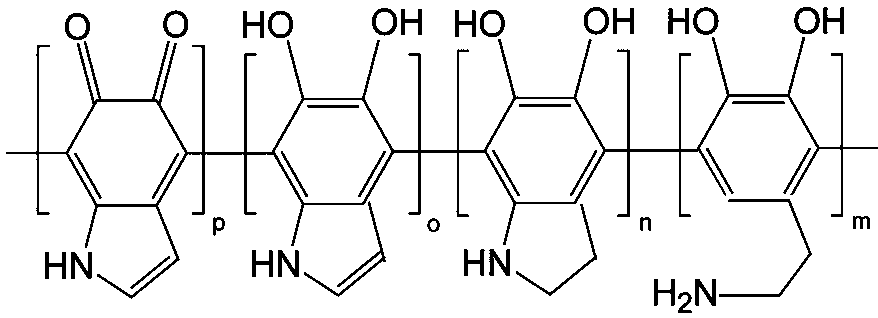

[0021] First, weigh a certain amount of dopamine hydrochloride (189.7 g / mol, Aladdin), and dissolve it in Tris (chemically pure, Aladdin), hydrochloric acid (chemically pure, Sinopharm Shenyang Reagent Factory), ethanol (chemically pure, Aladdin), Pure, Sinopharm Shenyang Reagent Factory) and ultrapure water (conductivity less than 18 MΩ -1 ), prepare a dopamine solution with a concentration of 1000 mmol / L in a weakly alkaline solution with pH=7.5 configured in a certain proportion. After leaving the above solution at room temperature for 24 hours, centrifugation, standing, filtering, washing, and drying the filter cake to obtain polydopamine solid particles. The structure of the polydopamine powder particles is as follows Figure 4 Shown. The relevant test results of the powder after drying are as follows Figure 5 , Image 6 with Figure 7 As shown, the mass fractions of dioxindole, indoledione, dopamine monomer, and polydopamine in polydopamine particles are 10%: 5%: 20%: 65...

Embodiment 3

[0023] First, weigh a certain amount of dopamine hydrochloride (189.7 g / mol, Aladdin), and dissolve it in tris (chemically pure, Aladdin), hydrochloric acid (chemically pure, Sinopharm Shenyang Reagent Factory), isopropanol (Chemical purity, Sinopharm Shenyang Reagent Factory) and ultrapure water (conductivity less than 18 MΩ -1 ), prepare a dopamine solution with a concentration of 1 mmol / L in an alkaline solution with pH=11 configured in a certain proportion. Then, immerse the aluminum-plastic film as the modified organic material, take it out after 24 h at room temperature, and rinse with deionized water for 2 h. Finally, it was dried for 8 h at 50°C in a vacuum environment. The thermal conductivity of the obtained polydopamine modified aluminum plastic film is increased by 12%, and the mass fractions of dioxindole, indoledione, dopamine monomer, and polydopamine in the polydopamine particles are 5%: 3%: 12%, respectively : 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com