Preparation method of nano-grade metal phosphide composite photo catalyst

A metal phosphide, nano-scale technology, used in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as poor stability and narrow band gap, and achieve high catalytic activity and synergy. , the effect of improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

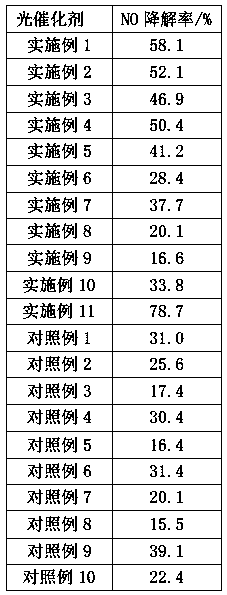

Examples

Embodiment 1

[0014] A preparation method of a nanoscale metal phosphide composite photocatalyst, the method comprising the following steps:

[0015] Step 1, mix the powdered Bi-V-O composite material obtained after drying with NaH 2 PO 2 Place them together in a tube furnace with a mass ratio of 5:1. The two are separated by quartz wool. Under the protection of Ar, heat up from room temperature at 20°C with a heating rate of 2°C / min and react at 350°C for 3 hours to obtain primary product;

[0016] Step 2. The primary product obtained after phosphating was cross-washed 5 times with deionized water and absolute ethanol, centrifuged at 8500r / min for 6min, and dried in an oven at 60°C to obtain black nano-scale BiP-V 3 P 5 Composite metal phosphides;

[0017] Step 3, put 25gBiP-V 3 P 5 The composite metal phosphide was put into an aluminum chloride solution with a mass fraction of 8% and stirred at 90°C for 5 hours, filtered, washed until neutral, dried, dispersed in ethanol-deionized a...

Embodiment 2

[0023] Step 4, 10g modified BiP-V 3 P 5 After drying with 35g of SBA-15 zeolite material, grind and pulverize, sieve with 600 mesh, mix and stir evenly at 90°C, disperse in ethanol-deionized aqueous solution, add 14g of cetyltrimethylammonium bromide in a water bath at 60°C Stir in medium for 4 hours, ultrasonically disperse for 30 minutes, suction filter, wash, vacuum dry to constant weight, grind and sieve to get BiP-V 3 P 5 / SBA-15 nanometer photocatalytic material. All the other steps are the same as in Example 1.

Embodiment 3

[0025] Step 4, 5g modified BiP-V 3 P 5 After drying with 35g of SBA-15 zeolite material, grind and pulverize, sieve with 600 mesh, mix and stir evenly at 90°C, disperse in ethanol-deionized aqueous solution, add 14g of cetyltrimethylammonium bromide in a water bath at 60°C Stir in medium for 4 hours, ultrasonically disperse for 30 minutes, suction filter, wash, vacuum dry to constant weight, grind and sieve to get BiP-V 3 P 5 / SBA-15 nanometer photocatalytic material. All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com