Additive of sintering material, and light, high-strength and high-efficiency water-storage water-permeable sintered brick and plate

A technology of sintered materials and admixtures, applied in the production and application of ceramic materials, household appliances, etc., can solve the problems of water storage, poor continuous water permeability, long firing time, high firing temperature, etc., to achieve water storage and sustainable Good water permeability, short firing time and low firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

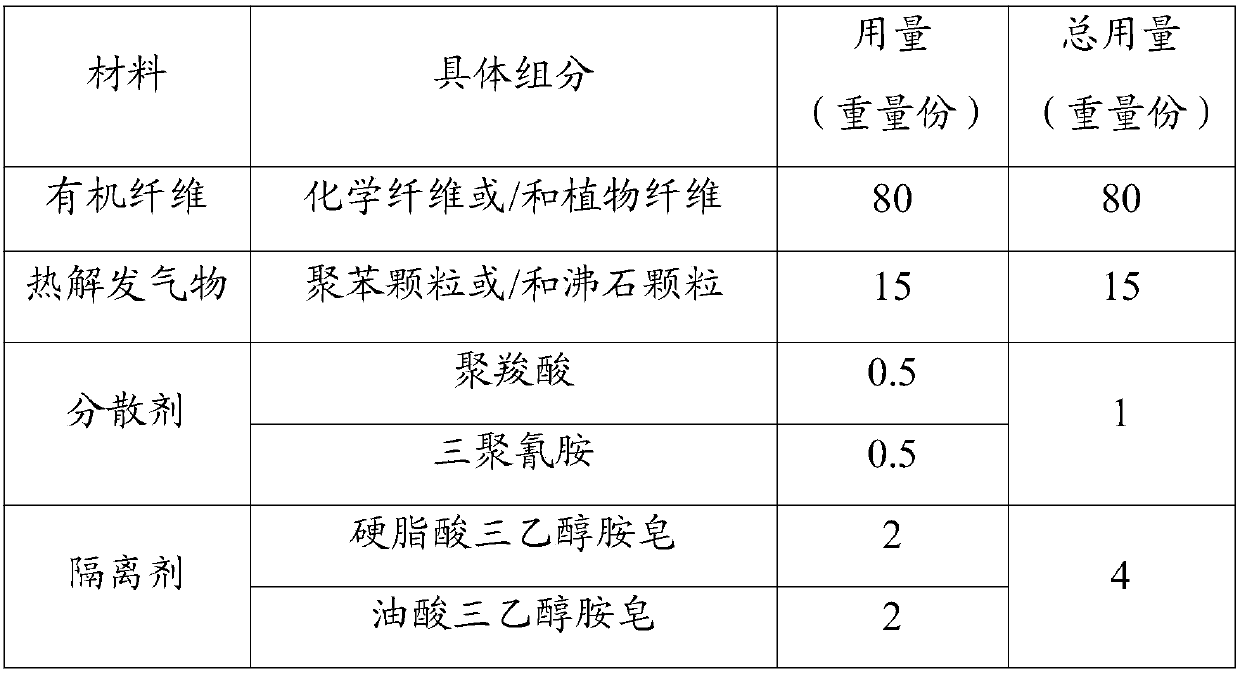

[0020] An admixture for sintered materials, the raw materials used for its preparation include: organic fibers, pyrolysis gas products, dispersants, and release agents, wherein the fibers include chemical fibers or / and plant fibers, and the pyrolysis gas products are polystyrene Or / and zeolite particles, the dispersant is polycarboxylic acid dispersant and melamine dispersant, the release agent is stearic acid triethanolamine soap and oleic acid triethanolamine soap, the components and specific amounts of the above raw materials are shown in Table 1.

[0021] The composition and concrete consumption of each raw material of table 1

[0022]

[0023] The preparation method of the above admixture comprises the following steps: (1) stirring and polymerizing the dispersant and release agent at a temperature of 60-80°C for 4-6 hours, and then cooling to room temperature; (2) adding the organic fiber and Pyrolysis gas products, stirring evenly.

[0024] After the above step (1) i...

Embodiment 2

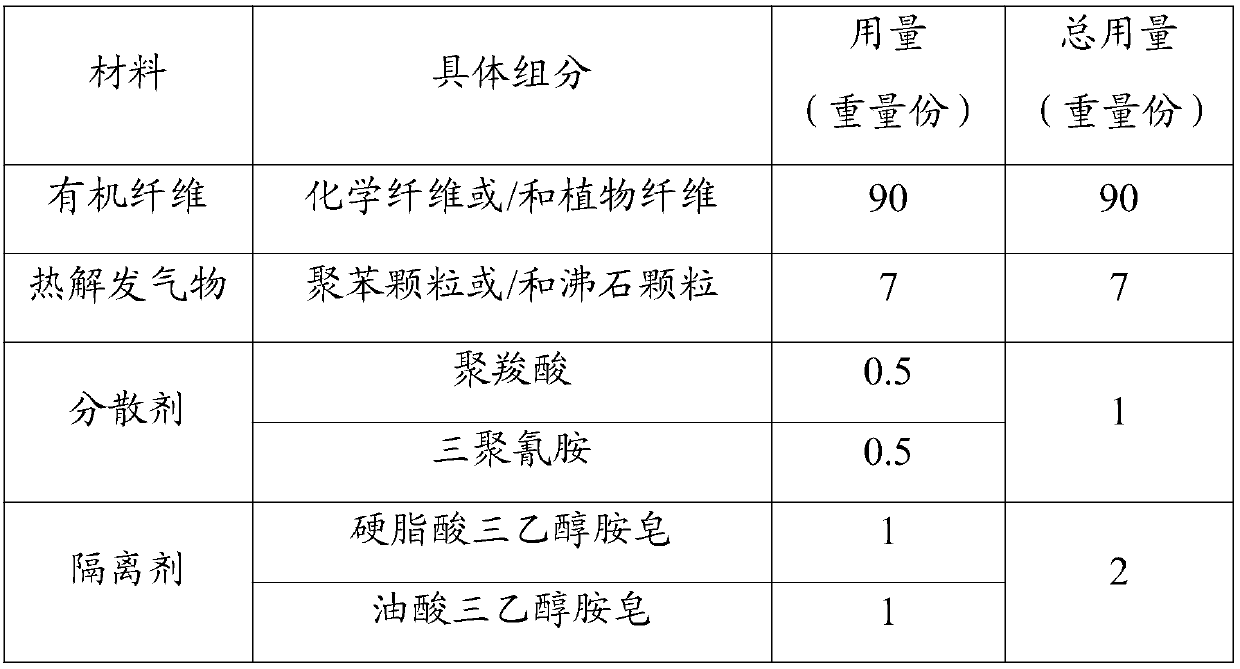

[0028] This example is similar to Example 1, and the components and specific dosages of the raw materials used to prepare the admixture are shown in Table 2.

[0029] The composition and specific consumption of each raw material of table 2

[0030]

Embodiment 3

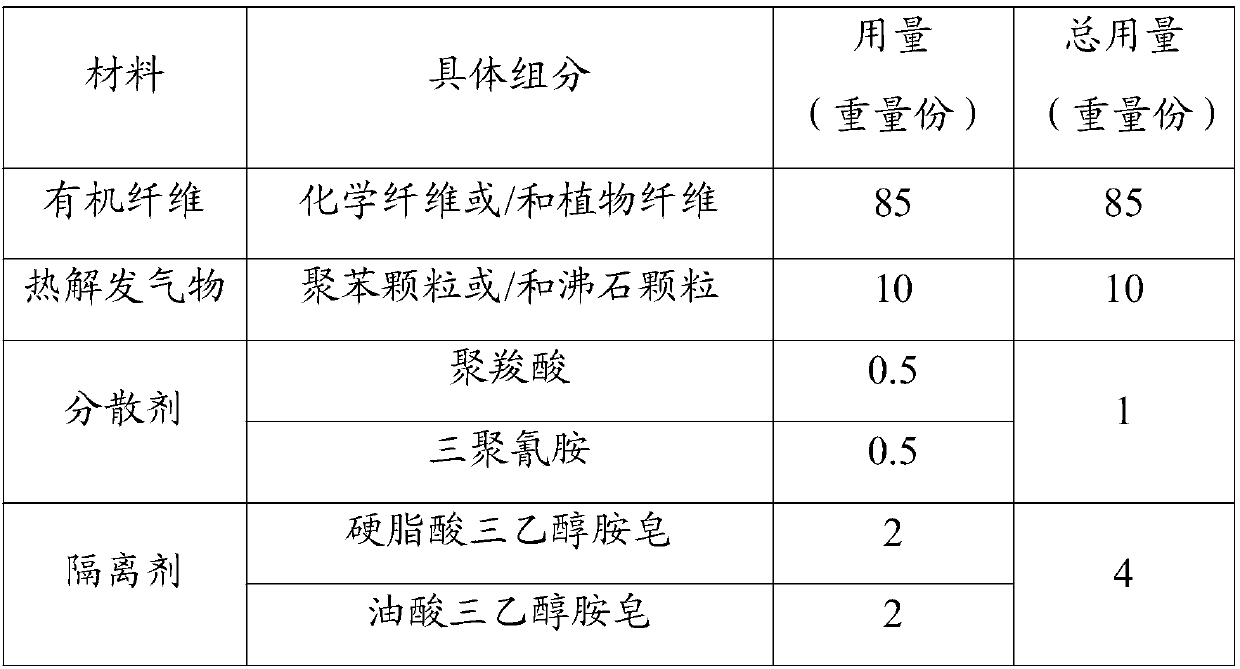

[0032] This example is similar to Example 1, and the components and specific dosages of the raw materials used to prepare the admixture are shown in Table 3.

[0033] The composition and concrete consumption of each raw material of table 3

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com