Composite membrane material for releasing nitric oxide by magnetic control as well as preparation method and application of composite membrane material

A technology of nitric oxide and composite membrane, applied in the field of biomedical engineering materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

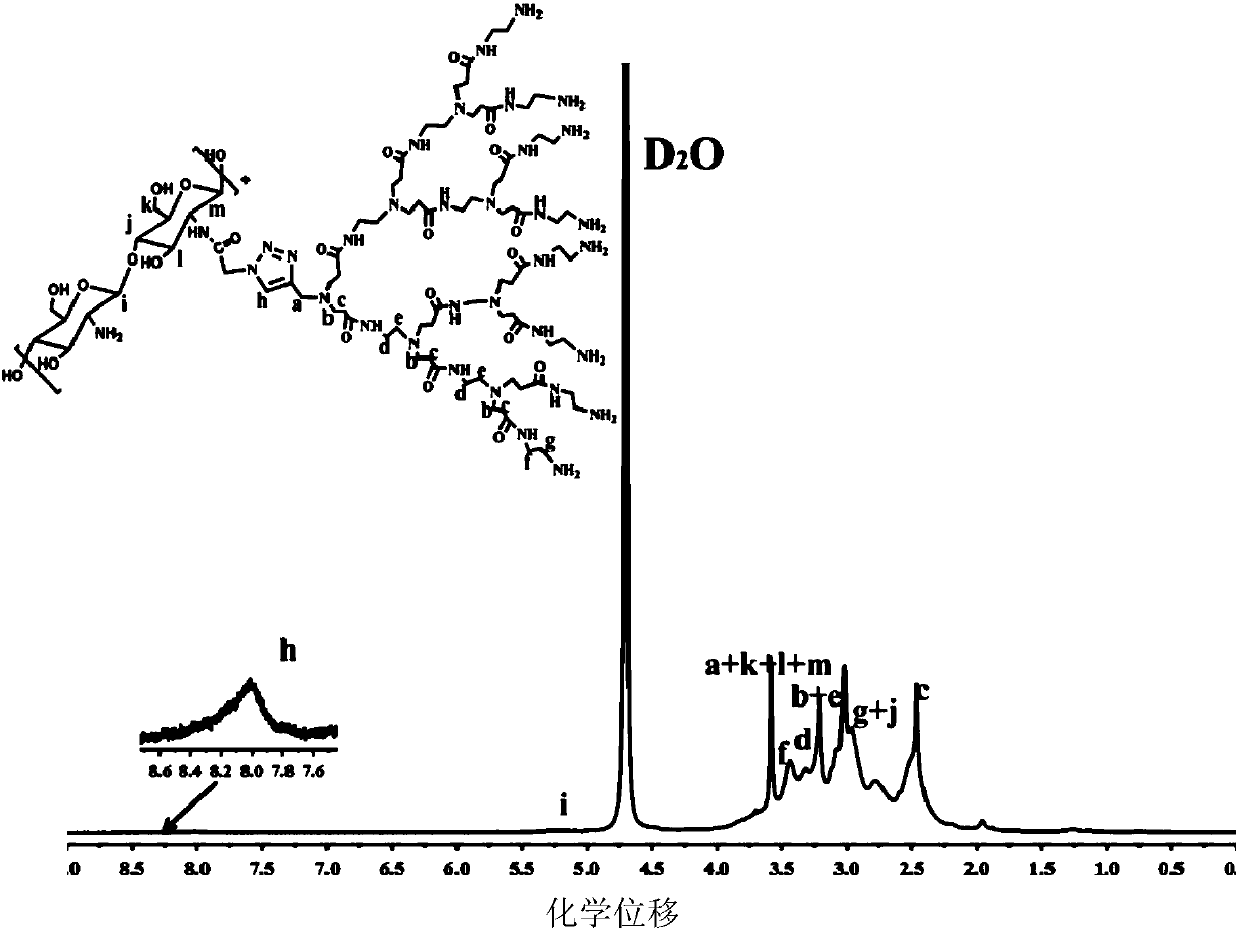

[0102] (1) Azide modified chitosan (CS-N 3 )Synthesis:

[0103] Azidoacetic acid (N 3 -CH2-COOH) was dissolved in N-N-dimethylformamide (DMF), and then sequentially added 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC·HCl) and N-hydroxysuccinimide (NHS) activation 30min, obtains in the azidoacetic acid mixed solution; After the activation finishes, chitosan (the molecular weight of CS is 2000, deacetylation degree 85%) is dissolved in pure water, then slowly adds into In the above mixed solution of azidoacetic acid, react at 35°C for 12h. The product was dialyzed in deionized water for 2 days, freeze-dried to obtain the product chitosan azide; wherein, the chitosan, 1-ethyl-(3-dimethylaminopropyl) carbodiimide salt The molar ratio of N,N-dimethylformamide (EDC·HCl), N-hydroxysuccinimide (NHS) and azidoacetic acid is 1:1.5:1.5:2; Add 5g azido acid meter in; Described pure water adds 5g chitosan in every 10ml.

[0104] (2) Synthesis of alkyne-containing pol...

Embodiment 2

[0107] (1) Azide modified chitosan (CS-N 3 )Synthesis:

[0108] Azidoacetic acid (N 3 -CH2-COOH) was dissolved in N-N-dimethylformamide (DMF), and then sequentially added 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC·HCl) and N-hydroxysuccinimide (NHS) was activated for 4h to obtain azidoacetic acid mixed solution; after the activation, chitosan (the molecular weight of CS was 20000, and the degree of deacetylation was 40%) was dissolved in pure water, and then slowly added to In the above mixed solution of azidoacetic acid, react at room temperature 25°C for 24h. The product was dialyzed in deionized water for 3 days, and freeze-dried to obtain the product azide chitosan. Among them, the chitosan, 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC·HCl), N-hydroxysuccinimide (NHS) and azidoacetic acid The molar ratio is 1:10:10:10; the N,N-dimethylformamide is based on the addition of 1g azide per 10ml; the pure water is based on the addition...

Embodiment 3

[0112] (1) Azide modified chitosan (CS-N 3 )Synthesis:

[0113] Azidoacetic acid (N 3 -CH2-COOH) was dissolved in N-N-dimethylformamide (DMF), and then sequentially added 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC·HCl) and N-hydroxysuccinimide (NHS) was activated for 2h to obtain azidoacetic acid mixed solution; after the activation, chitosan (the molecular weight of CS was 10000, and the degree of deacetylation was 60%) was dissolved in pure water, and then slowly added to In the above mixed solution of azidoacetic acid, react at room temperature at 5°C for 16h. The product was dialyzed in pure water for 2 days, and freeze-dried to obtain the product azide chitosan. Among them, the chitosan, 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC·HCl), N-hydroxysuccinimide (NHS) and azidoacetic acid The molar ratio is 1:5:5:5; the N,N-dimethylformamide is calculated by adding 3g azide in every 10ml; the pure water is added with 3g chitosan in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com