Method for modifying water-soluble dietary fibers of millet bran

A technology of dietary fiber and millet bran, applied in the field of food processing, can solve the problem of not being able to meet the requirement of 10% of high-quality dietary fiber, and achieve the effects of improving economic added value, good physiological activity, and good color and luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

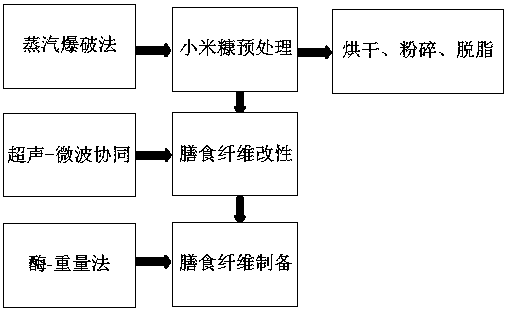

[0028] refer to figure 1 , the modification method of rice bran water-soluble dietary fiber uses red grain rice bran as raw material, pretreats it, then uses ultrasonic-microwave synergistic method to modify it, and finally adopts enzyme-gravimetric method to prepare water-soluble dietary fiber fiber, specifically comprising the steps of:

[0029] (1) Weigh 500g of millet bran into the gas explosion reactor for processing. Set the gas explosion pressure to 1.0 MPa and the gas explosion time to 90s. The millet bran was dried at 40 ℃ after air explosion pretreatment, and the moisture content was controlled within the range of 6% to 8%. Air explosion pretreatment millet bran was crushed through a 40-mesh sieve, and the fat was removed by petroleum ether Soxhlet extraction.

[0030] (2) Weigh the air-explosion pretreated millet bran, place it in the ultrasonic-microwave synergistic extractor, turn on the ultrasonic power, the material-liquid ratio is 1:60 (g / mL), the ultrasonic...

Embodiment 2

[0033] (1) Weigh 500g of millet bran into the gas explosion reactor for processing. Set the gas explosion pressure to 1.0 MPa and the gas explosion time to 90s. The millet bran was dried at 40 ℃ after air explosion pretreatment, and the moisture content was controlled within the range of 6% to 8%. Air explosion pretreatment millet bran was crushed through a 40-mesh sieve, and the fat was removed by petroleum ether Soxhlet extraction.

[0034] (2) Weigh the air-explosion pretreated millet bran, place it in the ultrasonic-microwave synergistic extraction apparatus, turn on the ultrasonic power, the solid-liquid ratio is 1:50 (g / mL), the ultrasonic-microwave synergy time is 50 min, and the microwave power is 500W.

[0035] (3) Transfer the reaction solution to the GDE enzyme culture digester, and add appropriate amount of high temperature resistant α - Amylase, neutral protease, and amyloglucosidase were used for enzymatic hydrolysis, and the pH values of the reaction soluti...

Embodiment 3

[0037] (1) Weigh 500g of millet bran into the gas explosion reactor for processing. Set the gas explosion pressure to 1.0 MPa and the gas explosion time to 90s. The millet bran was dried at 40°C after air explosion pretreatment, and the moisture content was controlled within the range of 6% to 8%. Air explosion pretreatment millet bran was crushed through a 40-mesh sieve, and the fat was removed by petroleum ether Soxhlet extraction.

[0038] (2) Weigh the air-explosion pretreated millet bran, place it in the ultrasonic-microwave co-extractor, turn on the ultrasonic power, the solid-liquid ratio is 1:50 (g / mL), the ultrasonic-microwave synergistic time is 60 min, and the microwave power is 550W.

[0039] (3) Transfer the reaction solution to the GDE enzyme culture digester, and add appropriate amount of high temperature resistant α - Amylase, neutral protease, and amyloglucosidase were used for enzymatic hydrolysis, and the pH values of the reaction solution were adjusted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com