A low-cost green preparation method of nano-copper

A nano-copper, low-cost technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high energy consumption, high pollution, high production cost, etc., achieve less alcohol consumption, The raw materials are cheap and easy to obtain, and the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

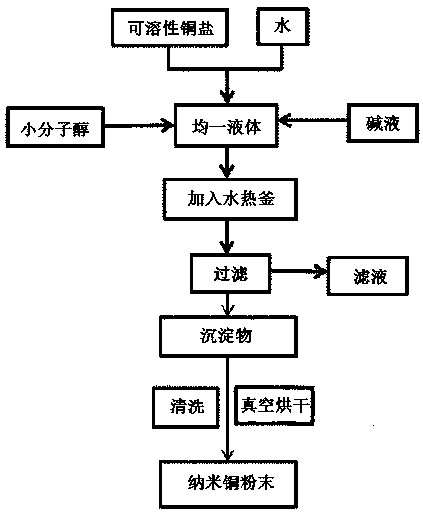

Method used

Image

Examples

Embodiment 1

[0020] (1) Take 0.004 mol of copper sulfate pentahydrate, dissolve it in 25 ml of water, stir to a homogeneous solution, add 25 ml of ethanol, 25 ml of 2.5 mol / L NaOH solution, and stir for 1 h.

[0021] (2) Transfer the mixed liquid and solid obtained above to a hydrothermal kettle, and heat it in an oven at 160 O C for 12 h and cooled to room temperature.

[0022] (3) The mixed liquid and solid in the reaction kettle are filtered to obtain the filtrate and solid, and after the solid is washed with water and ethanol, 40 O C was dried in vacuum for 24 h to obtain nano-copper powder.

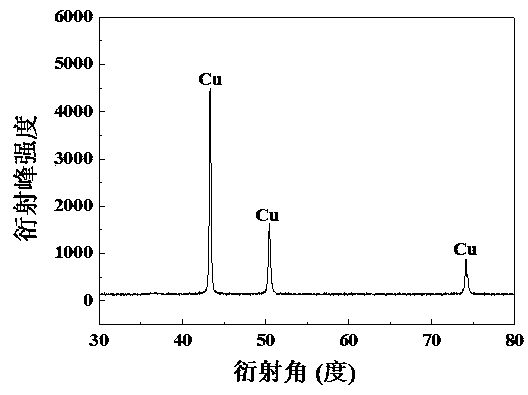

[0023] Gained nano-copper powder, through X-ray diffraction, such as figure 2 As shown, diffraction occurs only at the diffraction angles of 43.3, 50.4, and 74.0 degrees, indicating that the substance prepared by the water-ethanol thermal method is nano-copper.

Embodiment 2

[0025] (1) Take 0.003 mol of copper nitrate trihydrate, dissolve it in 25 ml of water, stir until a homogeneous solution, add 15 ml of ethanol, 15 ml of 2.0 mol / L NaOH solution, and stir for 2 h.

[0026] (2) Transfer the mixed liquid and solid obtained above to a hydrothermal kettle, and heat it in an oven at 180 O C conditions for 8h, cooled to room temperature.

[0027] (3) The mixed liquid and solid in the reaction kettle are filtered to obtain the filtrate and solid. After the solid is washed with water and ethanol, 50 O C was dried in vacuum for 24 h to obtain nano-copper powder.

Embodiment 3

[0029] (1) Take 0.002 mol of copper chloride, dissolve it in 25 ml of water, stir until a homogeneous solution, add 15 ml of ethanol, 10 ml of 1.5 mol / L NaOH solution, and stir for 2 h.

[0030] (2) Transfer the mixed liquid and solid obtained above to a hydrothermal kettle, and heat it in an oven at 200 O C for 10 h and cooled to room temperature.

[0031] (3) The mixed liquid and solid in the reaction kettle are filtered to obtain the filtrate and solid, and the solid is washed with water and ethanol for 30 O C was dried in vacuum for 36 h to obtain nano-copper powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com