Tin-based paste braze solder and preparation method for same

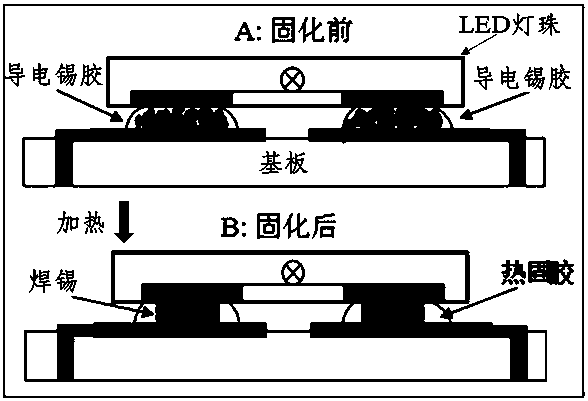

A brazing solder and tin-based technology, which is applied to welding equipment, welding/cutting media/materials, welding media, etc., can solve the problem of short effective use time of tin-based paste brazing solder, increase storage process and use process complexity , Long time to return to room temperature and other issues, to achieve the effect of no need for cleaning, prolonged performance retention time, and less residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

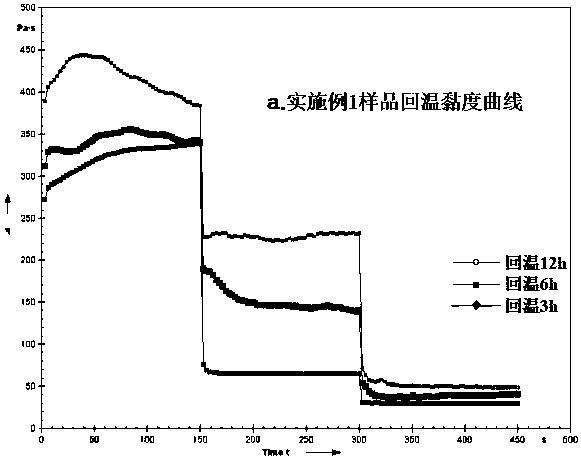

Embodiment 1

[0026] Embodiment 1 prepares tin-based paste brazing solder according to the following steps:

[0027] Step ①: Prepare thermosetting epoxy resin adhesive, also referred to as curable adhesive: Weigh 100g of bisphenol A epoxy resin E51, 5g of amine curing agent dicyandiamide, 1g of imidazole curing accelerator, 0.05g of dicyandiamide The foaming agent polyoxyethylene polyoxypropanolamine ether is added to the polytetrafluoroethylene beaker in turn, and the mixture is evenly stirred to form a curable epoxy resin adhesive, referred to as curable adhesive, which is stored at a low temperature of 0-10°C for later use.

[0028] Step ②: Deploying flux glue: Weigh benzyl alcohol, sebacic acid, adipic acid, diphenylguanidine hydrobromide, Add n-butylamine hydrochloride, liquid hydrogenated castor oil, benzotriazole and curable glue, and add the above-mentioned substances into an enamel cup in turn to prepare a flux glue, and store it at a temperature of 0-10°C for later use.

[0029] ...

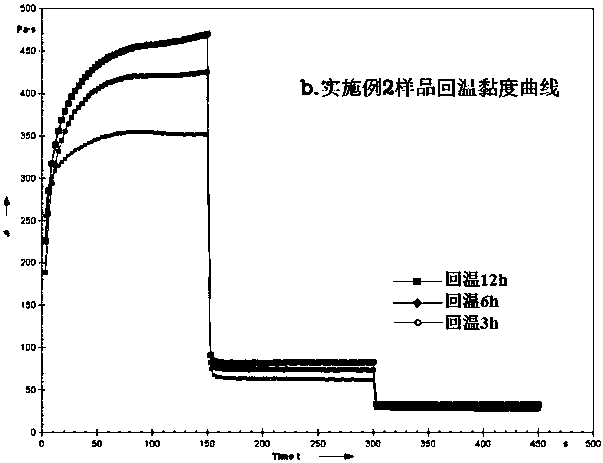

Embodiment 2

[0030] The preparation procedure of Example 2 is the same as that of Example 1, and the part that is different from Example 1 is: in the step ② of the preparation of Example 2, the components and mass ratios of the thermosetting flux adhesive are prepared according to the following proportions: benzyl alcohol / glutaric acid / adipic acid / diphenylguanidine hydrobromide / dimethylamine hydrochloride / hydrogenated castor oil / hydroquinone / curable gum = 12 / 10 / 6 / 14 / 3 / 4 / 2 The ratio of / 49 is added to the enamel cup in turn to prepare soldering flux, and it is stored in a refrigerator at 0~10°C for later use; Step 3 of Example 2 is used to prepare conductive solder paste: take out the soldering paste in step ② and return it to room temperature before weighing it 1.7g, and then add 8.3g of Si96.5Ag3Cu0.5 tin powder with a particle size of 5~15 µm, and mix evenly to obtain a tin-based paste brazing solder.

[0031] The tin-based paste brazing solder prepared in Examples 1 and 2 ...

Embodiment 3

[0033] The preparation steps of Example 3 are the same as that of Example 1, and the part that is different from Example 1 is: the steps of the preparation of Example 3 ② The components and ratios of the deployment of thermosetting flux adhesives are changed, and the prepared in Example 3 The thermosetting soldering flux in step ② is formulated according to the following ratio: dimethylacetamide / sebacic acid / glutaric acid / diphenylguanidine hydrobromide / cyclohexylamine hydrochloride / hydrogenated castor oil / carbonic acid ring The ratio of hexylamine / curable glue=20 / 19 / 15 / 21 / 4 / 2 / 1 / 18 (mass ratio) is weighed and prepared, mixed and refrigerated for later use; the tin-based paste brazing prepared in step ③ of Example 3 The soldering process is: take out the soldering paste in step ②, return to room temperature and weigh 1.7g, then add 8.3g of Si42Bi57.6Ag0.4 tin powder with a particle size of 5~15 µm, and mix evenly to obtain tin-based Paste brazing solder. Other steps and process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com