Porous graphite as well as preparation method and application thereof

A porous graphite and microporous membrane technology, applied in chemical instruments and methods, inorganic chemistry, electrical components, etc., can solve the problems of high cost and complex preparation process, and achieve the promotion of biofilm formation, simple preparation method, and increased ratio. The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of microbial fuel cell (MFC):

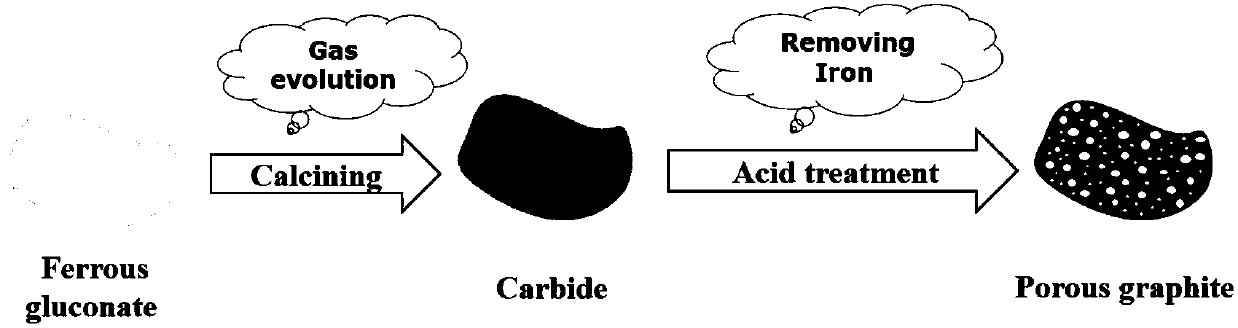

[0044] (1) The preparation method of porous graphite, such as figure 1 shown, including the following steps:

[0045] (1) Put 6g of ferrous gluconate powder into a porcelain ark, raise the temperature to 150°C at 5°C / min in a tube furnace atmosphere for 3 hours, then raise the temperature to 900°C at 2°C / min and hold for 2 hours to obtain carbide powder.

[0046] (2) Soak the carbide powder obtained in step (1) in 40 mL of hydrochloric acid (20%) for 2 hours, vacuum filter, and then rinse with deionized water until neutral.

[0047] (3) Step (2) was repeated several times, and the obtained powder was dried at 50° C. to obtain porous graphite.

[0048] (2) Preparation of MFC anode: Soak the carbon felt in 1% HCl and 1% NaOH solution for 1 h, then wash until neutral, dry for later use; weigh the prepared carbon felt in step (1) 27mg of porous graphite was dispersed in 1mL of deionized water, and then mixed with 1mL of binder ...

Embodiment 2

[0052] Preparation of microbial fuel cell (MFC):

[0053] (1) a preparation method of porous graphite, comprising the following steps:

[0054] (1) Dissolve 6g of ferrous gluconate powder in water and then dry it at 80°C, raise the temperature to 150°C at 5°C / min under argon atmosphere in a tube furnace and keep it for 3 hours, then raise the temperature to 900°C at 2°C / min and hold it for 2 hours, The carbide powder was obtained.

[0055](2) Soak the carbide powder obtained in step (1) in 40 mL of hydrochloric acid (20%) for 2 hours, and then rinse it with deionized water until neutral.

[0056] (3) Step (2) is repeated several times, and the obtained product is dried at 50° C. to obtain porous graphite.

[0057] (2) Preparation of MFC anode: Soak the carbon felt in 1% HCl and 1% NaOH solution for 1 h, then wash until neutral, dry for later use; weigh the prepared carbon felt in step (1) 27mg of porous graphite was dispersed in 1mL of deionized water, and then mixed with 1...

Embodiment 3

[0061] Preparation of microbial fuel cell (MFC):

[0062] (1) the preparation method of porous graphite, comprises the following steps:

[0063] (1) Put 6g of ferrous gluconate powder into a porcelain ark, raise the temperature to 1000°C at 2°C / min under an argon atmosphere in a tube furnace and hold it for 2h to obtain carbide powder.

[0064] (2) Soak the carbide powder obtained in step (1) in 40 mL of concentrated hydrochloric acid for 2 h, vacuum filter, and then rinse with deionized water until neutral.

[0065] (3) Step (2) was repeated once, and the obtained powder was dried at 100° C. to obtain porous graphite.

[0066] (2) Preparation of MFC anode: Soak the carbon felt in 1% HCl and 1% NaOH solution for 1 h, then wash until neutral, dry for later use; weigh the prepared carbon felt in step (1) 27mg of porous graphite was dispersed in 1mL of deionized water, and then mixed with 1mL of binder (10wt% polytetrafluoroethylene) on the pretreated carbon felt (3cm×3cm×0.5cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com