Method for preparing high-purity methane through adsorption separation methane and nitrogen in simulated moving bed

A simulated moving bed, adsorption separation technology, applied in the field of simulated moving bed adsorption and separation of methane and nitrogen to prepare high-purity methane, can solve the problems of undiscovered research reports and blanks in basic theoretical research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following provides a specific embodiment of a method for preparing high-purity methane by adsorbing and separating methane and nitrogen in a simulated moving bed of the present invention.

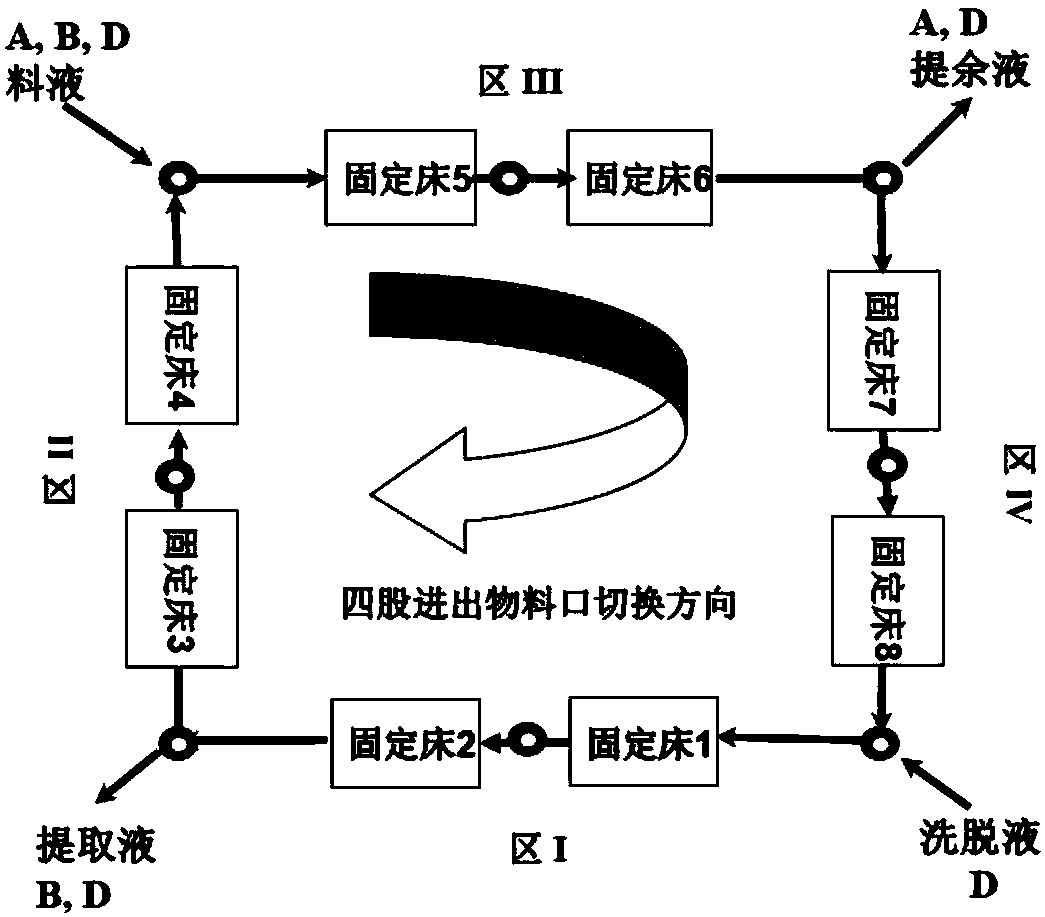

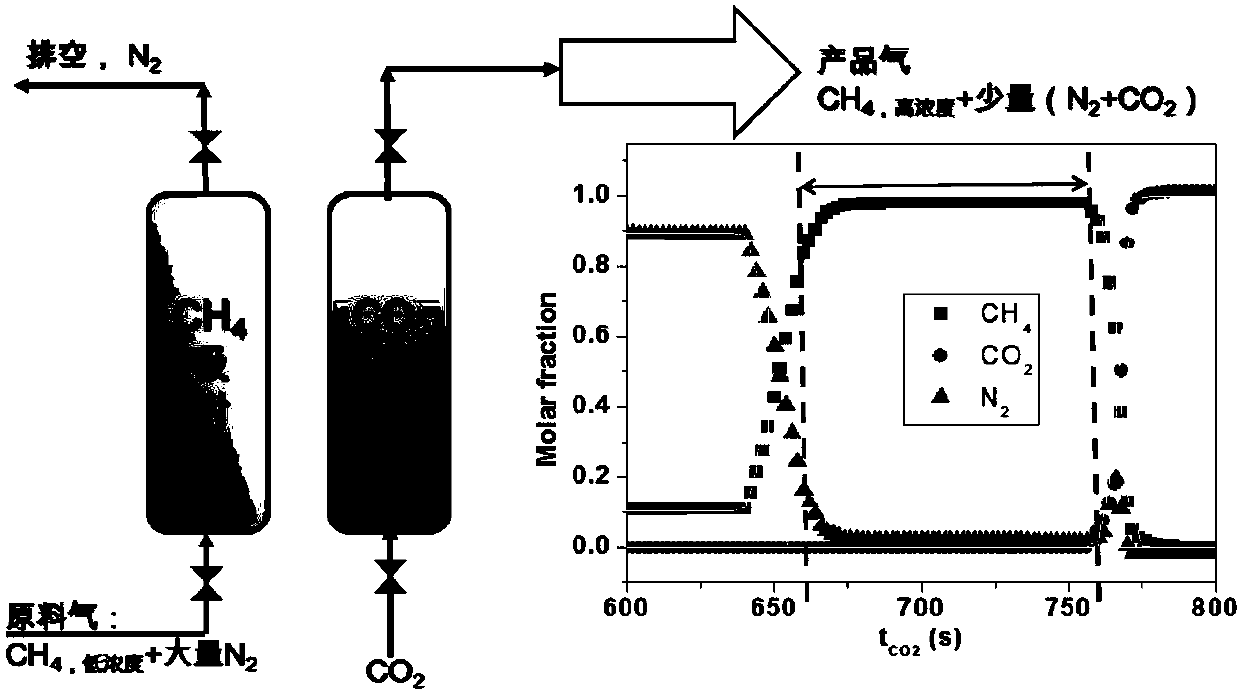

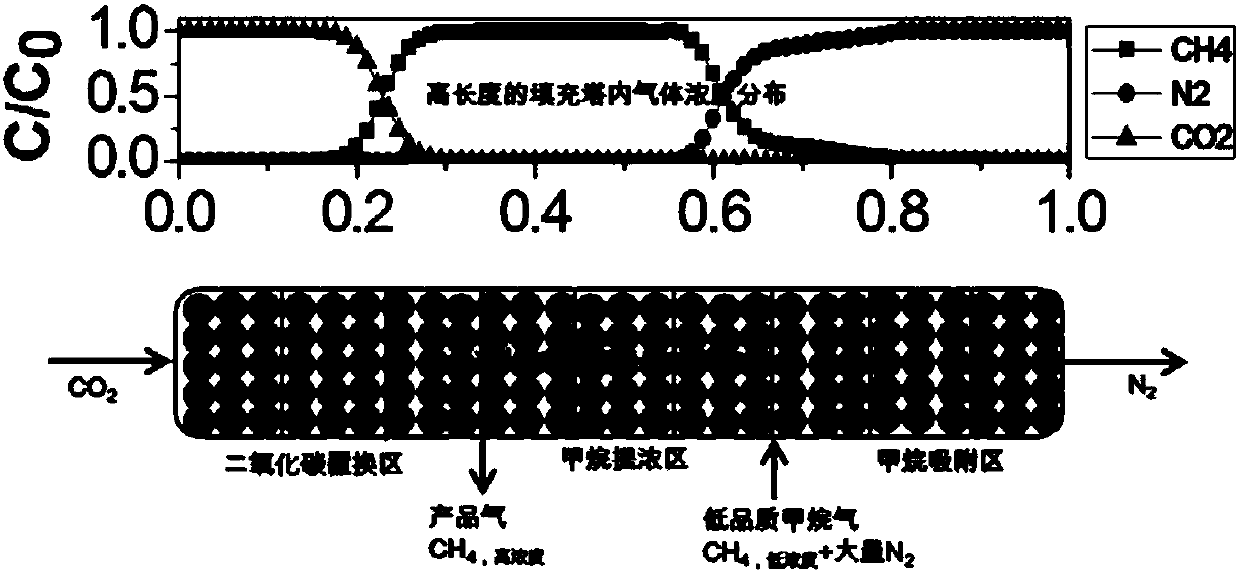

[0052]The simulated moving bed system is composed of ten adsorbent packed towers, and the height of each packed tower should be less than 1 meter to reduce the pressure drop in the bed during vacuum desorption of carbon dioxide and improve the desorption rate of the adsorbent. The filled adsorbent can be any material of carbon-based adsorbent material, zeolite and high silicon molecular sieve; the shape of the adsorbent can be granular, fibrous or honeycomb. The simulated moving bed system is equipped with five gas input and output ports, low-quality methane feed gas input port, nitrogen gas discharge port, carbon dioxide replacement gas input port, high-purity methane product gas output port and desorbed carbon dioxide recovery port. These five gas input and output ports divide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com