Device for producing dimethyl disulfide co-produced dimethyl trisulfide

A technology for the co-production of dimethyl trisulfide and methyl mercaptan from dimethyl disulfide, which is applied in the preparation of hydrogenated polysulfides/polysulfides, the preparation of organic compounds, chemical instruments and methods, etc., and can solve the refining and separation process Complicated, large equipment investment, no dimethyl disulfide and other problems, to achieve the effect of reasonable process flow configuration, simple refining and separation process, and good reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

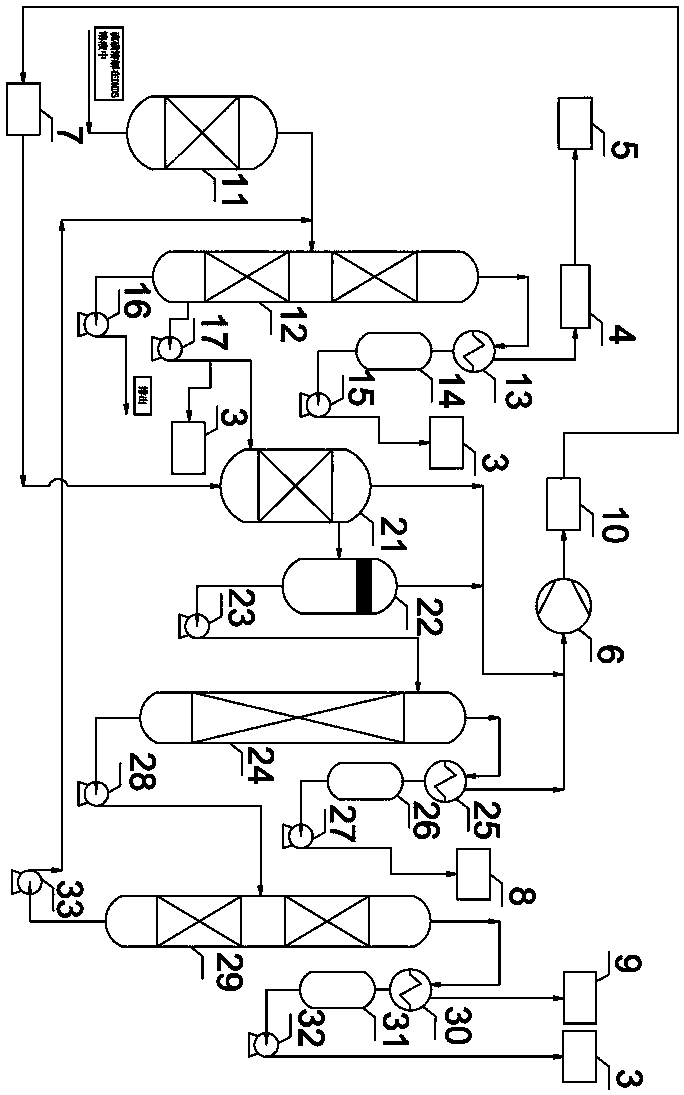

[0021] A device for producing dimethyl disulfide and co-producing dimethyl trisulfide, characterized in that it includes a first reaction mechanism 1, a second reaction mechanism 2 and a finished product collection mechanism 3, and also includes a vacuum mechanism 4 and a waste gas treatment mechanism 5 , a compression mechanism 6, a methyl mercaptan addition mechanism 7, a methyl mercaptan vulcanization mechanism 8, an incineration mechanism 9 and a methyl mercaptan synthesis mechanism 10, and the first reaction mechanism 1 has four output ends that are respectively connected to the finished product collection mechanism 3 , recombination mechanism, vacuum mechanism 4 and second reaction mechanism 2 are connected, and described second reaction mechanism 2 has four output ends and described finished product collection mechanism 3, incineration mechanism 9, methyl mercaptan vulcanization mechanism 8 and the first reaction mechanism respectively Agency 1 is connected.

[0022] 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com