Composite electrode material and preparation method thereof

An electrode material and nano-composite technology, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problems of volume change, battery capacity drop, electrode active material falling off, etc., and achieve simple synthesis process, easy operation, and improved diffusion speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

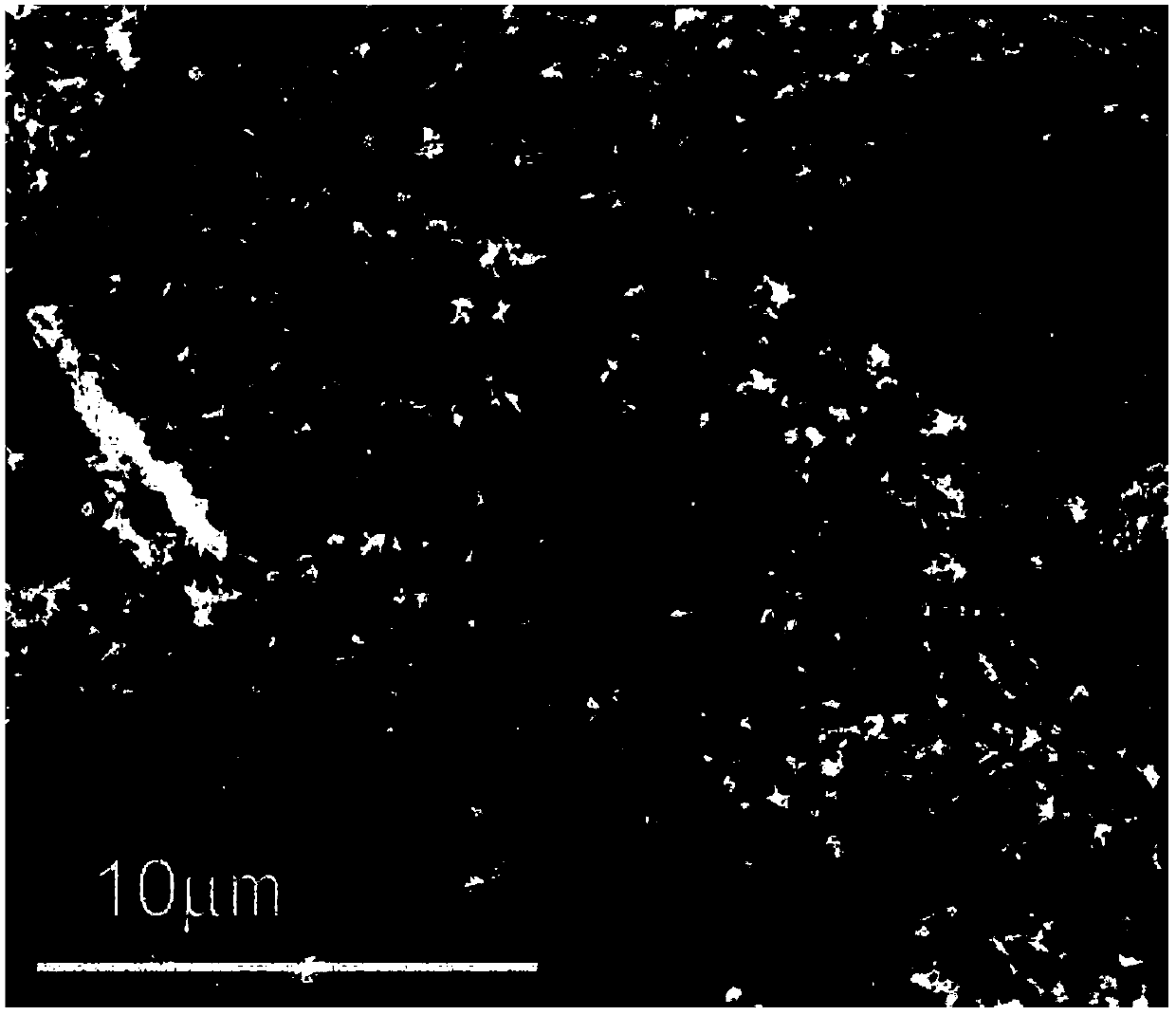

[0026] Embodiment 1: prepare graphene / nickel sulfide nanocomposite electrode material mass ratio is the composite material of 5: 95 and measure its electrochemical lithium storage performance, concrete steps are as follows:

[0027] (1): prepare the graphene oxide organic solution of 0.2mg / mL;

[0028] (2): Weigh 1.64g of nickel acetate tetrahydrate and dissolve it in the graphene oxide organic solution. After stirring and dissolving, add 20uL of carbon disulfide and continue stirring for 5 minutes. In a blast drying oven, the reaction was carried out at 180° C. for 12 hours to obtain a block graphene / nickel sulfide gel, and the graphene / nickel sulfide nanocomposite material was obtained after freeze-drying.

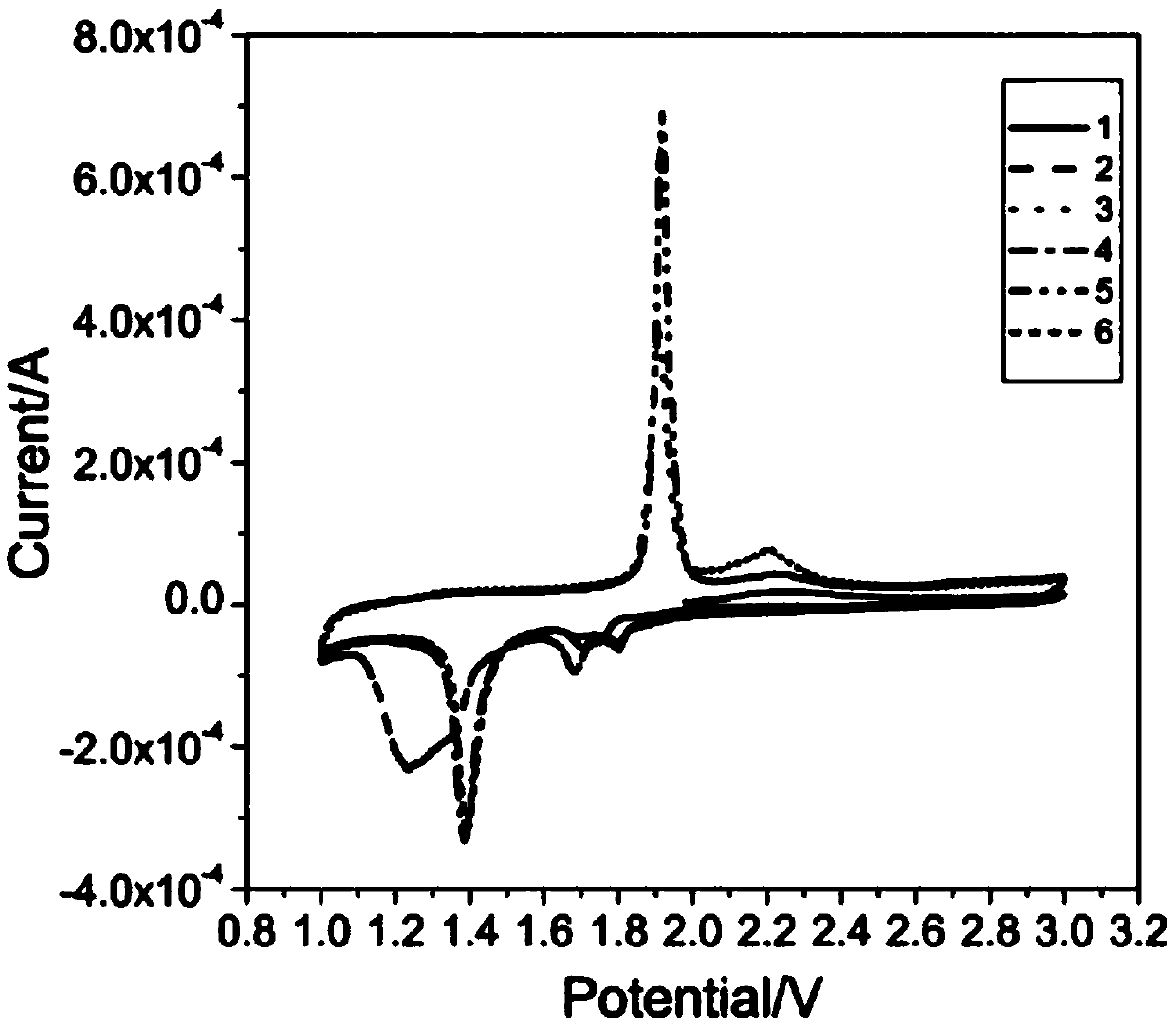

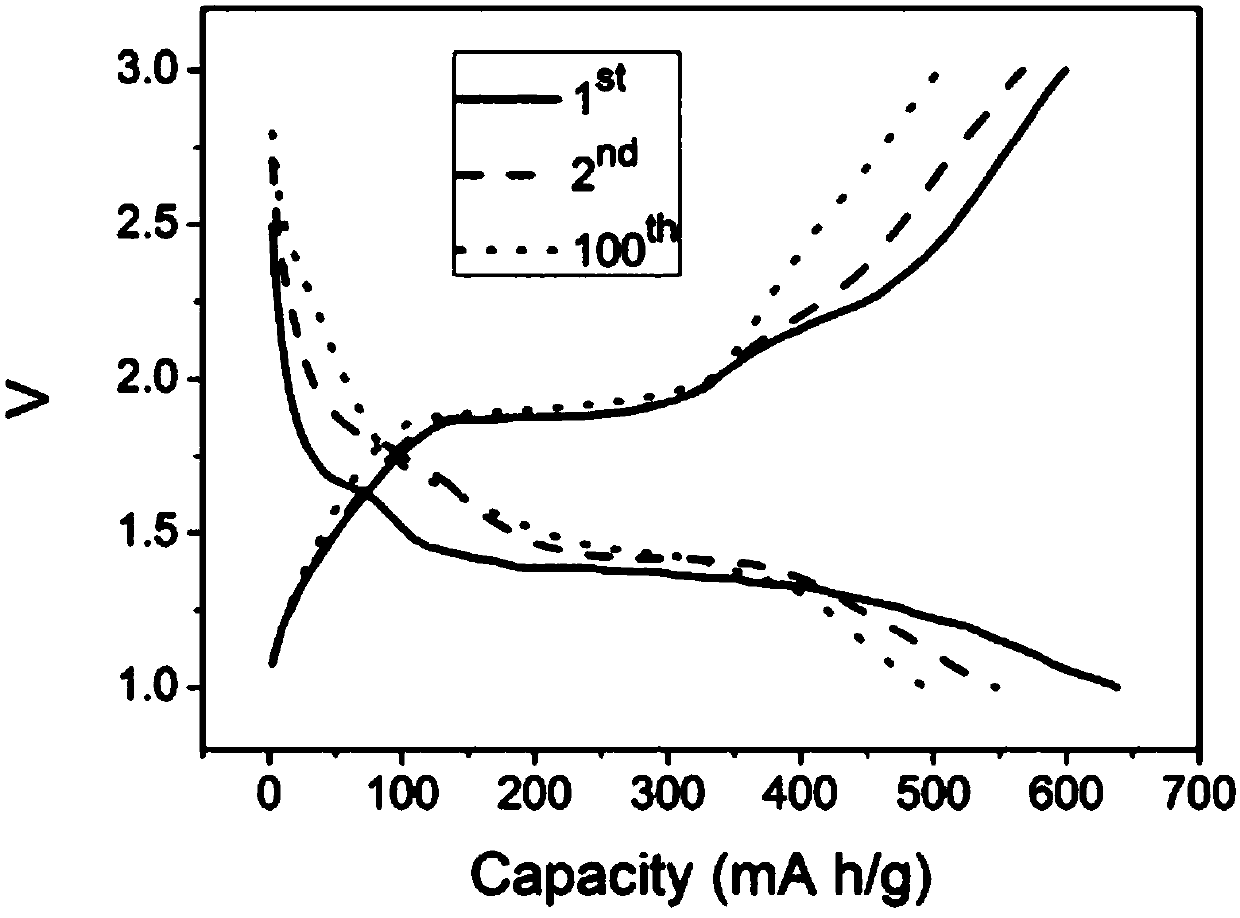

[0029] (3): Electrochemical lithium storage performance test of graphene / nickel sulfide nanocomposite:

[0030] A certain mass ratio of graphene / nickel sulfide nanocomposite (80%) and a certain mass ratio of super carbon black (10%) and a mass ratio of 10% PVDF are disp...

Embodiment 2

[0031] Embodiment 2: preparation graphene / nickel sulfide nanocomposite electrode material mass ratio is the composite material of 10:90 and measures its electrochemical lithium storage performance, concrete steps are as follows:

[0032] (1): prepare the graphene oxide organic solution of 0.5mg / mL;

[0033] (2): Weigh 1.64g of nickel acetate tetrahydrate and dissolve it in the graphene oxide organic solution. After stirring and dissolving, add 20uL of carbon disulfide and continue stirring for 5 minutes. In a blast drying oven, the reaction was carried out at 180° C. for 12 hours to obtain a block graphene / nickel sulfide gel, and the graphene / nickel sulfide nanocomposite material was obtained after freeze-drying.

[0034] (3): Electrochemical lithium storage performance test of graphene / nickel sulfide nanocomposite:

[0035] A certain mass ratio of graphene / nickel sulfide nanocomposite (80%) and a certain mass ratio of super carbon black (10%) and a mass ratio of 10% PVDF are...

Embodiment 3

[0036] Embodiment 3: preparation graphene / nickel sulfide nanocomposite electrode material mass ratio is the composite material of 20:80 and measures its electrochemical lithium storage performance, and concrete steps are as follows:

[0037] (1): prepare the graphene oxide organic solution of 1.0mg / mL;

[0038] (2): Weigh 1.64g of nickel acetate tetrahydrate and dissolve it in the graphene oxide organic solution. After stirring and dissolving, add 20uL of carbon disulfide and continue stirring for 5 minutes. In a blast drying oven, the reaction was carried out at 180° C. for 12 hours to obtain a massive graphene / nickel sulfide gel, which was freeze-dried to obtain a graphene / nickel sulfide nanocomposite material.

[0039](3): Electrochemical lithium storage performance test of graphene / nickel sulfide nanocomposite:

[0040] A certain mass ratio of graphene / nickel sulfide nanocomposite (80%) and a certain mass ratio of super carbon black (10%) and a mass ratio of 10% PVDF are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com