Compound protein formaldehyde scavenger as well as preparation method and application of compound protein formaldehyde scavenger

A formaldehyde scavenger and composite protein technology, which is applied in the field of formaldehyde scavenger, can solve the problems of high toxicity of scavenger compounds, limited adsorption capacity, and insufficient environmental protection, and achieve the effects of wide application range, low raw material cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

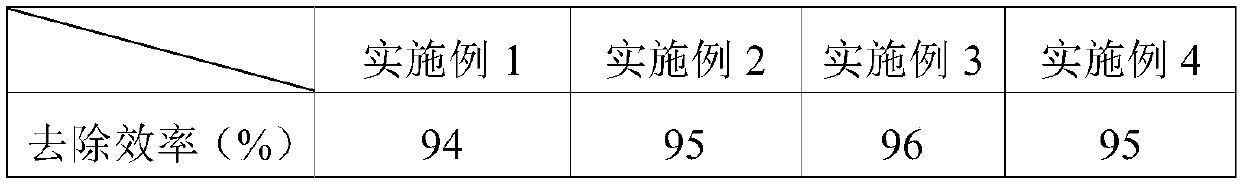

Examples

Embodiment 1

[0024] A compound protein formaldehyde scavenger comprises the following raw materials by weight percentage: 10% vegetable protein, 0.2% acid protease, 10% animal protein, 0.2% alkaline protease, 0.3% oxidizing agent, 0.3% decolorizing agent, and 1.0% penetrant , Moisturizer 8%, Water 70%.

[0025] Its preparation method is as follows:

[0026] (1) Take vegetable protein, add water with 3 times the mass of vegetable protein, stir evenly, add acid protease, heat to 50°C for enzymatic hydrolysis for 3 hours, add oxidizing agent for oxidation for 3 hours, add decolorizing agent, heat to 80°C, decolorize for 2 hours, filter , the filtrate is cooled, crystallized, and dried to obtain vegetable protein decomposition products;

[0027] (2) Take animal protein, add water with 3 times the mass of animal protein, stir evenly, add compound protease, heat to 60°C for enzymolysis for 3 hours, add oxidizing agent for oxidation for 4 hours, add decolorizing agent, heat to 80°C, decolorize f...

Embodiment 2

[0030] A compound protein formaldehyde scavenger comprises the following raw materials by weight percentage: 12% vegetable protein, 0.4% acidic protease, 12% animal protein, 0.4% alkaline protease, 0.5% oxidizing agent, 0.2% decolorizing agent, and 1.5% penetrating agent , Humectant 5%, Water 68%.

[0031] Its preparation method is as follows:

[0032] (1) Take vegetable protein, add water twice the mass of vegetable protein, stir evenly, add acid protease, heat to 45°C for enzymatic hydrolysis for 4 hours, add oxidizing agent for oxidation for 4 hours, add decolorizing agent and heat to 85°C, decolorize for 1.5 hours, Filtrate, cool the filtrate, crystallize, and dry to obtain vegetable protein decomposition products;

[0033] (2) Take animal protein, add water twice the mass of animal protein, stir evenly, add alkaline protease, heat to 50°C for enzymatic hydrolysis for 4 hours, add oxidizing agent for oxidation for 4 hours, add decolorizing agent, heat to 85°C, and decolor...

Embodiment 3

[0036] A compound protein formaldehyde scavenger comprises the following raw materials by weight percentage: 15% vegetable protein, 0.6% acidic protease, 15% animal protein, 0.6% alkaline protease, 1.0% oxidizing agent, 1.0% decolorizing agent, 1.8% penetrating agent , Humectant 8%, Water 57%.

[0037] Its preparation method is as follows:

[0038] (1) Take vegetable protein, add water with 1.5 times the mass of vegetable protein, stir evenly, add acid protease, heat to 40°C for enzymatic hydrolysis for 5 hours, add oxidizing agent for oxidation for 5 hours, add decolorizing agent, heat to 90°C, decolorize for 1 hour, filter , the filtrate is cooled, crystallized, and dried to obtain vegetable protein decomposition products;

[0039] (2) Take animal protein, add water with 1.5 times the mass of animal protein, stir evenly, add alkaline protease, heat to 40°C for enzymolysis for 5 hours, add oxidizing agent for oxidation for 5 hours, add decolorizing agent, heat to 85°C, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com