Graphene modified waterborne polyurethane resin and preparation method thereof

A water-based polyurethane and graphene modification technology, applied in polyurea/polyurethane coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of easy foaming, high surface tension, and poor water resistance of the coating film, and achieve Good antistatic properties, UV resistance, anti-corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

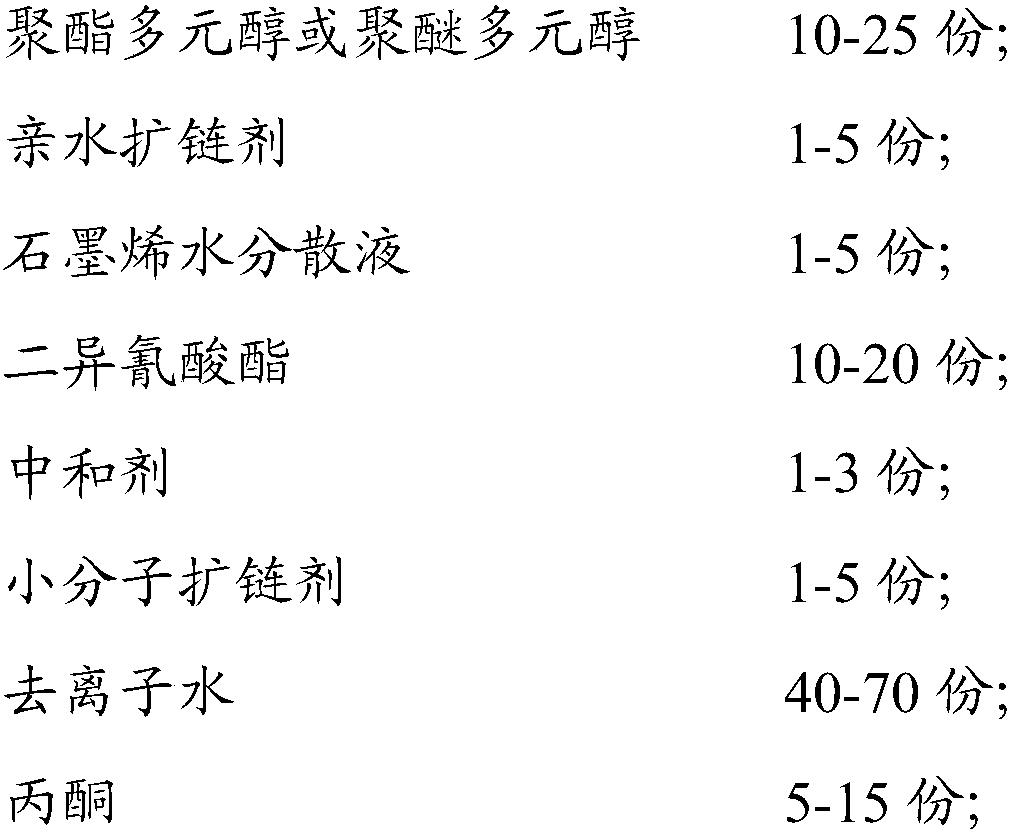

Method used

Image

Examples

Embodiment 1

[0026] A kind of graphene modified waterborne polyurethane resin and preparation method thereof, its preparation technology is as follows:

[0027] a. In a four-necked bottle equipped with a thermometer, a condenser, and an agitator, add 10 parts of polyester polyol, 2 parts of dimethylol propionic acid, and 1 part of graphene aqueous dispersion, and heat to 100 ℃, stir for 1.5 hours to fully remove the moisture in the raw materials;

[0028] b. Immediately pass nitrogen after the vacuum is stopped, cool the four-neck bottle to 60°C, add 10 parts of TDI, and react for 3 hours; add 7 parts of acetone, measure the NCO value, and stop the reaction when the measured value is close to the theoretically calculated value;

[0029] c. Stop feeding nitrogen, continue stirring, lower the temperature to 40°C, add 1 part of triethylamine to react for 10 minutes, add 67 parts of deionized water under vigorous stirring, and continue stirring at high speed for 10 minutes;

[0030] d. Slowly...

Embodiment 2

[0032] A kind of graphene modified waterborne polyurethane resin and preparation method thereof, its preparation technology is as follows:

[0033] a. Add 18 parts of polyester polyol, 3 parts of methyldiethanolamine, and 2 parts of graphene aqueous dispersion into a four-necked bottle equipped with a thermometer, condenser, and stirrer, and heat to 105°C under vacuum conditions. Stir for 1.5h to fully remove the moisture in the raw materials;

[0034] b. Immediately pass nitrogen after the vacuum is stopped, cool the four-necked bottle to 65°C, add 13 parts of HDI, and react for 3.5 hours; add 12 parts of acetone, measure the NCO value, and stop the reaction when the measured value is close to the theoretically calculated value;

[0035] c. Stop feeding nitrogen, continue stirring, cool down to 38°C, add 1.5 parts of ammonia water to react for 13 minutes, add 48 parts of deionized water under vigorous stirring, and continue stirring at high speed for 15 minutes;

[0036] d. ...

Embodiment 3

[0038] A kind of graphene modified waterborne polyurethane resin and preparation method thereof, its preparation technology is as follows:

[0039] a. In a four-necked bottle equipped with a thermometer, a condenser, and an agitator, add 18 parts of polyether polyol, 3 parts of sodium ethylenediaminoethanesulfonate, and 3 parts of graphene aqueous dispersion, and heat under vacuum conditions To 115°C, stir for 1.5 hours to fully remove the moisture in the raw materials;

[0040] b. Immediately pass nitrogen after the vacuum is stopped, cool the four-necked bottle to 80°C, add 15 parts of IPDI, and react for 4 hours; add 13 parts of acetone, measure the NCO value, and stop the reaction when the measured value is close to the theoretically calculated value;

[0041] c. Stop feeding nitrogen, continue stirring, lower the temperature to 40°C, add 2.5 parts of dimethylethanolamine to react for 20 minutes, add 41.5 parts of deionized water under vigorous stirring, and continue stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com