A kind of polyimide nanofiber film and preparation method thereof

A nanofiber membrane, polyimide technology, applied in the chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., can solve the problem of reducing the heat-resistant temperature of polyimide membranes, increasing the production steps of fiber membranes, and having limited strengthening effect. and other problems, to achieve the effect of improving mechanical properties and heat resistance, improving mechanical properties, and enhancing designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

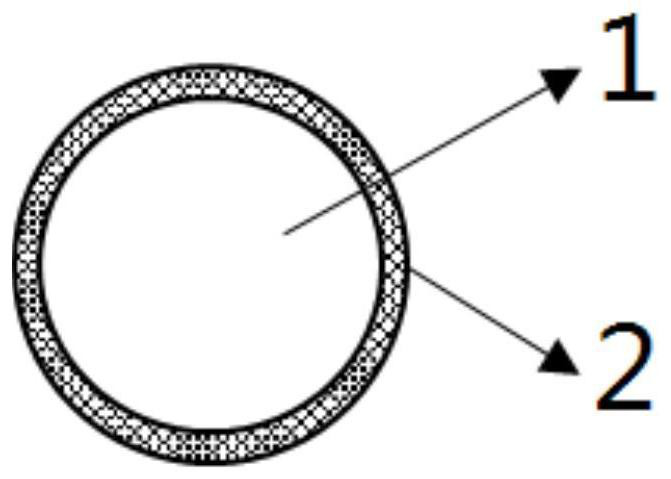

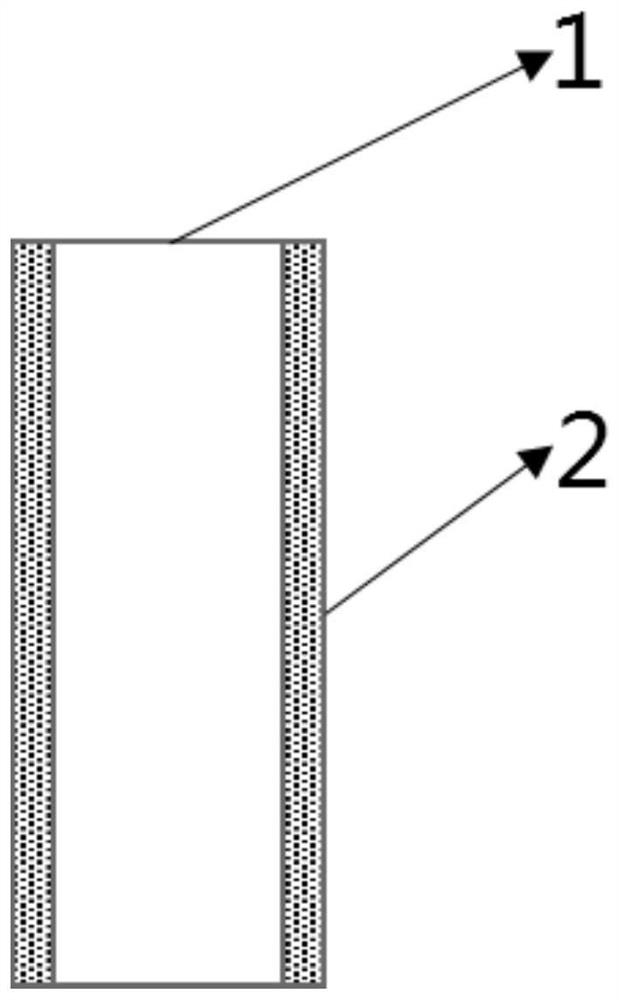

[0064] Such as figure 2 The polyimide nanofiber membrane shown can use a nested concentric electrospinning material nozzle, the first polyimide is located in the inner layer, and the second polyimide is located in the outer layer, completely covering the All sides of the first polyimide.

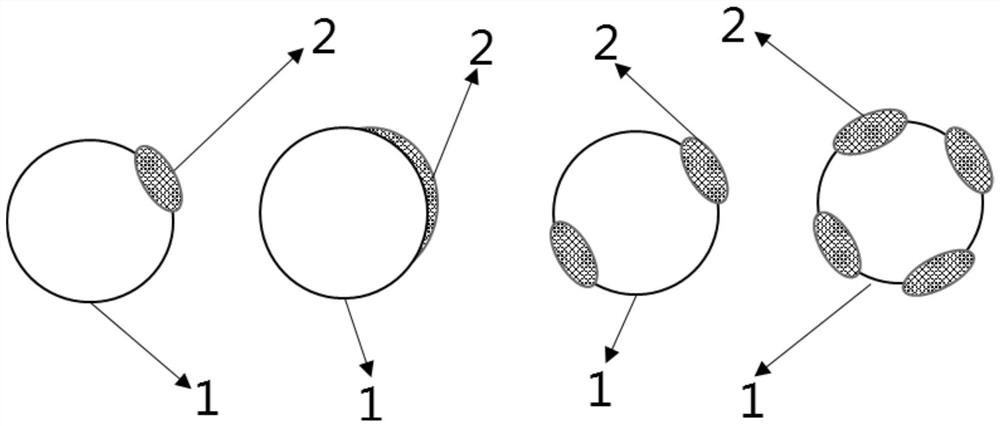

[0065] Such as Figure 4 In the polyimide nanofiber membrane shown, the second polyimide is located on the outer layer of the first polyimide, but only covers part of the surface of the first polyimide. Equally, those skilled in the art can also design according to common common sense can prepare such as Figure 4 The material nozzles described in and similar positional relationships.

[0066] The heat-resistant temperature measuring method of the present invention is: thermomechanical analysis (TMA)

[0067] The method for measuring the mechanical strength of the present invention is as follows: use a standard dumbbell-shaped cutter to cut the nanofiber membrane into a stretched sample...

Embodiment 1

[0069] Take polyimide A and polyimide C and dissolve them in DMAc respectively, and their respective concentrations are both: 20%. The rotational viscosity of solution A is 400cp (25°C, 600rpm), and the rotational viscosity of solution C is 900cp (25°C, 600rpm); put grade A polyimide in the storage material connected to the inner spray hole of coaxial electrospinning room; place the brand C polyimide solution in the storage room connected to the outer spray hole of coaxial electrospinning; control the liquid supply speed of the outer layer to be 5 times the liquid supply speed of the inner layer; at a voltage of 15Kv, Receiving at a receiving distance of 20cm, forming a film, drying the polyimide nanofiber primary product film, and then placing it under a flat vulcanizing machine for hot pressing at a temperature of about 230°C to obtain polyimide nanofibers membrane.

Embodiment 2

[0071] Take brand B polyamic acid and brand C polyimide and dissolve them in DMAc respectively, wherein the concentration of solution B is 10%, and the rotational viscosity is 1200cp (25°C, 600rpm), the concentration of solution C is 23%, and the rotational viscosity is 1300cp (25°C, 600rpm); put the brand B polyimide solution in the storage room connected to the inner spray hole of the coaxial electrospinning; put the brand C polyimide solution in the coaxial electrospinning The storage chamber connected to the outer spray hole of the outer layer; the liquid feeding speed of the outer layer is controlled to be 7 times of the liquid feeding speed of the inner layer; under the voltage of 20Kv and the receiving distance of 20cm, it is received and formed into a film, and the polyimide The primary amine nanofiber film was dried, and then placed in a gradient heating environment for gradient heating. The temperature was gradually raised to 250°C within 2 hours, and kept at 250°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| rotational viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com