Method for preparing microfluidic channels in glass by simple hot-pressing process

A technology of microfluidic channel and hot-pressing process, which is applied in the directions of laboratory containers, chemical instruments and methods, laboratory utensils, etc. The effect of non-toxic pollution, simple and easy preparation method and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

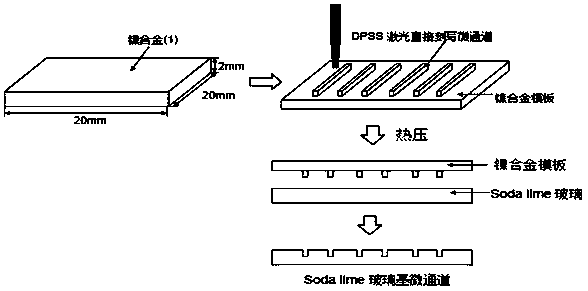

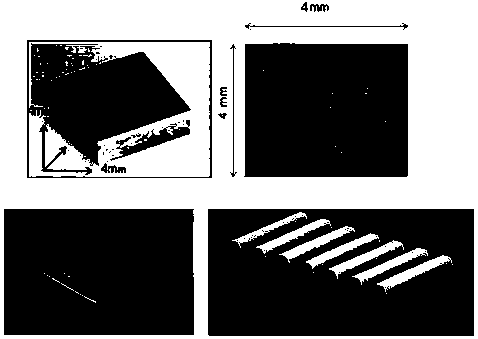

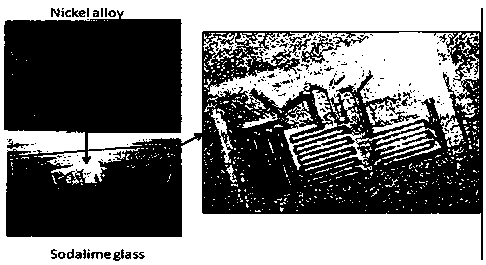

Embodiment 1

[0020] 1) Nickel alloy & template and glass surface treatment: use an optical polisher to polish the surface so that the roughness does not exceed 100 microns and the flatness is good, then wash with acetone, and then rinse and dry repeatedly with deionized water. 2) Make a template pattern according to actual needs, make it by drawing software and send it to the computer connected to the laser. The parameters of DPSS laser writing nickel alloy microchannel template are set as: 30kHz frequency, 15W laser power, 120mm / s writing speed, and repeat 100 times. 3) Hot-pressed glass-based microfluidic channel: put nickel alloy template and slide glass on Align under the microscope, place the compact in the muffle furnace, raise the temperature to 580 degrees at 15 degrees per minute, hold for 5 minutes to release the internal tension of the template and glass, and then raise the temperature to 660 degrees at a rate of 10 degrees per minute , and kept for 20 minutes, then cooled to 58...

Embodiment 2

[0025] 1) Nickel alloy & template and glass surface treatment: use an optical polisher to polish the surface so that the roughness does not exceed 100 microns and the flatness is good, then wash with acetone, and then rinse and dry repeatedly with deionized water. 2) Make a template pattern according to actual needs, make it by drawing software and send it to the computer connected to the laser. The parameters of DPSS laser writing nickel alloy microchannel template are set as: 30kHz frequency, 15W laser power, 120mm / s writing speed, and repeat 100 times. 3) Hot-pressed glass-based microfluidic channel: put nickel alloy template and slide glass on Align under the microscope, place in the furnace and raise the temperature to 580 degrees at 15 degrees per minute, keep for 5 minutes to release the internal tension of the template and glass, then raise the temperature to 660 degrees at a rate of 10 degrees per minute, and keep it for 20 minutes. The temperature is lowered to 580 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com