Preparation method of large-particle-size porous high-specific-surface silicon dioxide microspheres

A technology of high specific surface area and silicon dioxide, applied in the direction of silicon dioxide and silicon oxide, can solve the problems of narrow particle size control range, poor structure controllability, cumbersome process, etc., and achieve good uniformity, low cost, and easy preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

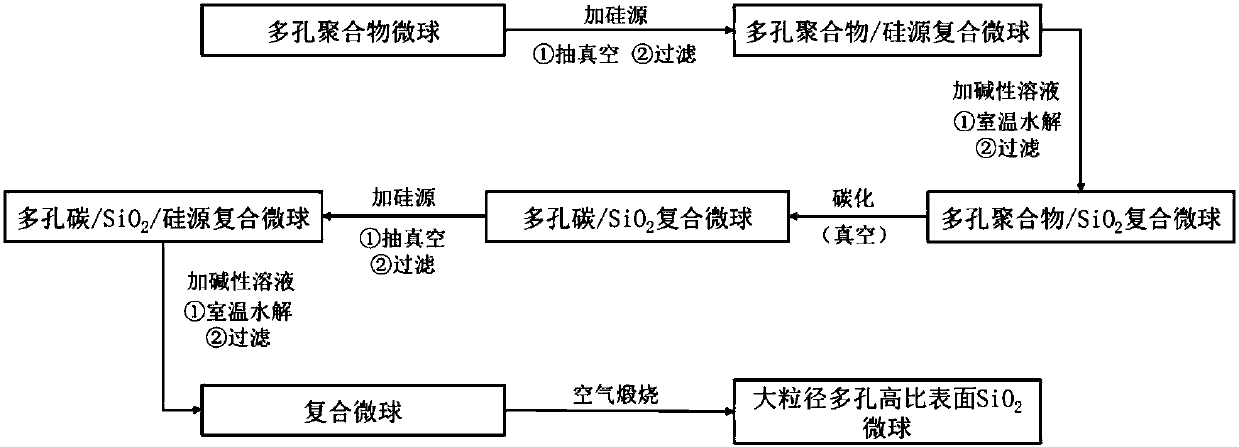

Method used

Image

Examples

Embodiment 1

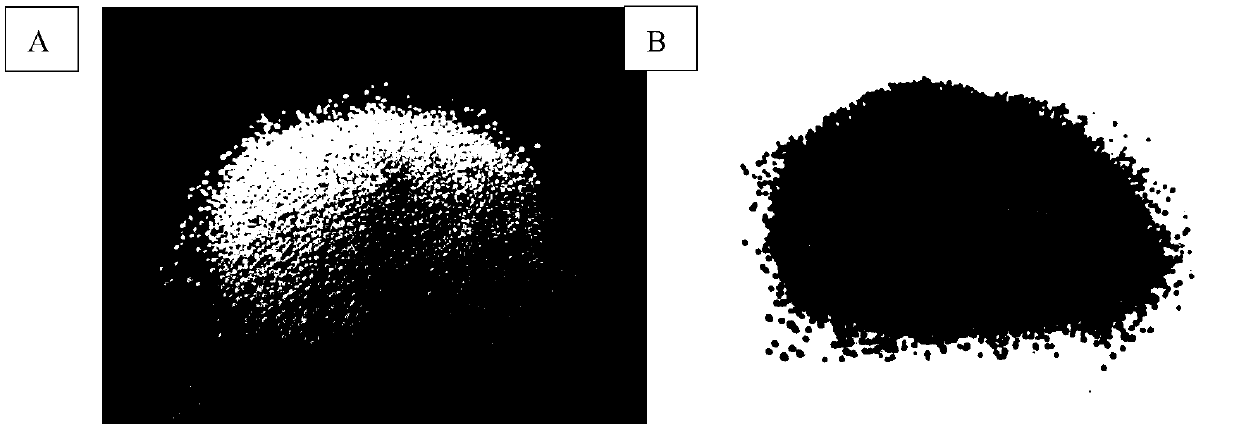

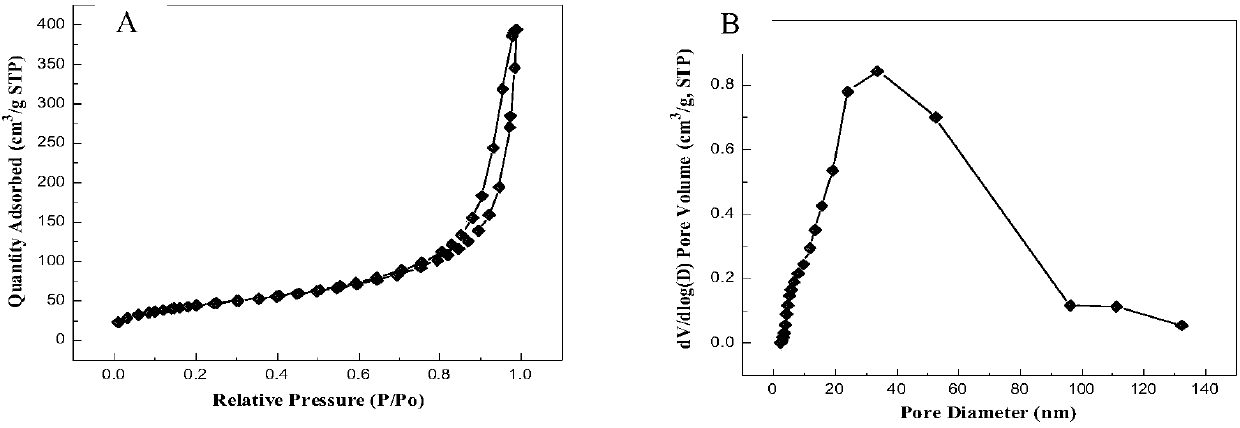

[0024] Example 1: Large particle size porous high specific surface silica microspheres

[0025] Take porous polystyrene microspheres, put them into a reaction bottle, and add tetraethyl orthosilicate to it until the liquid level does not exceed the porous polystyrene microspheres; vacuumize until no bubbles overflow in tetraethyl orthosilicate, and filter to obtain Porous polystyrene / tetraethyl orthosilicate composite microspheres; the obtained porous polystyrene / tetraethyl orthosilicate composite microspheres were transferred to a three-neck flask, and ammonia water was added thereto, stirring was started, and the porous polystyrene The volume ratio of tetraethyl orthosilicate composite microspheres to ammonia water is 1:5, and the pH of ammonia water is 10; after reacting at room temperature for 60 minutes, filter to obtain porous polystyrene / SiO 2 Composite microspheres; the resulting porous polystyrene / SiO 2 The composite microspheres were vacuum carbonized at 500 °C for ...

Embodiment 2

[0026] Example 2: Large particle size porous high specific surface silica microspheres

[0027] Take porous polymethyl methacrylate microspheres, put them into a reaction bottle, and add methyl orthosilicate to it until the liquid level does not exceed the porous polymethyl methacrylate microspheres; After the bubbles overflowed, filter to obtain porous polymethyl methacrylate / orthosilicate composite microspheres; transfer the obtained porous polymethyl methacrylate / orthosilicate composite microspheres to a three-necked flask, Add sodium hydroxide aqueous solution to it, start stirring, wherein the volume ratio of porous polymethyl methacrylate / orthosilicate composite microspheres and sodium hydroxide aqueous solution is 1:7, and the pH of sodium hydroxide aqueous solution is 12; room temperature reaction After 40min, filter to obtain porous polymethyl methacrylate / SiO 2 Composite microspheres; the resulting porous polymethylmethacrylate / SiO 2 The composite microspheres were...

Embodiment 3

[0028] Example 3: Large particle size porous high specific surface silica microspheres

[0029] Take porous polyacrylonitrile microspheres, put them into a reaction bottle, and add propyl orthosilicate to it until the liquid level does not exceed the porous polyacrylonitrile microspheres; vacuumize until no bubbles overflow in the propyl orthosilicate, and filter to obtain Porous polyacrylonitrile / orthopropyl silicate composite microspheres; transfer the obtained porous polyacrylonitrile / orthopropyl silicate composite microspheres into a three-neck flask, and add potassium hydroxide aqueous solution to it, start stirring, and the porous polyacrylonitrile The volume ratio of polyacrylonitrile / propyl orthosilicate composite microspheres to potassium hydroxide aqueous solution is 1:6, and the pH of potassium hydroxide aqueous solution is 14; after reacting at room temperature for 30 minutes, filter to obtain porous polyacrylonitrile / SiO 2 Composite microspheres; the resulting por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com