Method for synthesizing ammonia

A technology of synthetic ammonia and gas furnace, applied in the field of synthetic ammonia, which can solve the problems of high environmental pollution, low oxygen concentration, and low gas production of a single furnace, and achieve the effects of wide adaptability of coal types, low fuel requirements, and low gas outlet temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and embodiments.

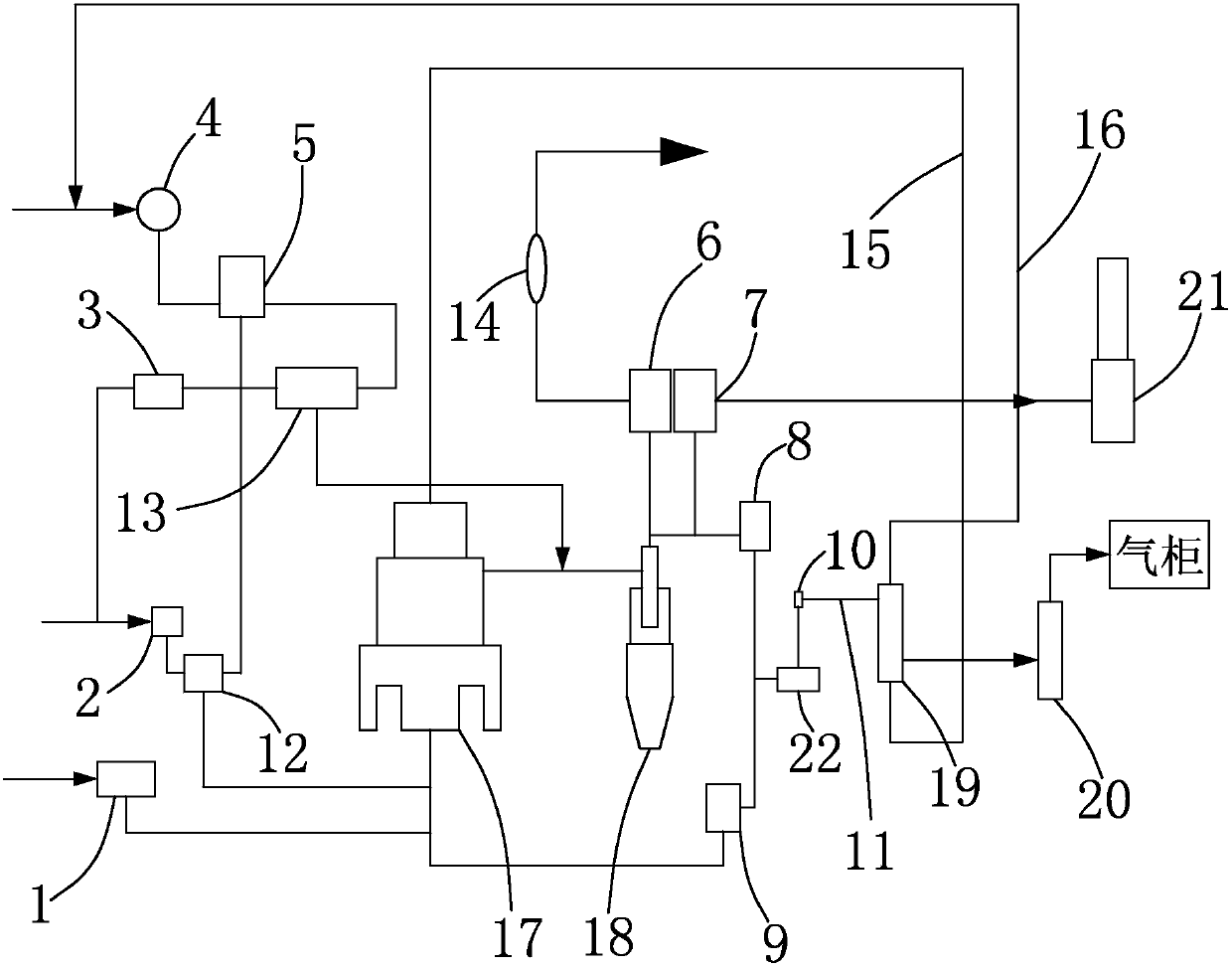

[0020] see figure 1 , is a schematic diagram of the method of the present invention for synthesizing ammonia in a fixed bed. The method for synthesizing ammonia comprises the following steps: providing an air separation system, an oxygen-enhancing blower, an upward-blowing oxygen-enhancing air valve 2, a gas furnace 17, a gas scrubber 20 and a gas cabinet, and mixing pure oxygen from the air separation system with air. The oxygen-enhancing air is prepared in the oxygen-enhancing blower, and enters the gas furnace 17 through the upward-blowing oxygen-enhancing air valve 2, where the oxygen-enhancing air and steam react with the carbon in the gas furnace 17 to generate high-temperature gas. It enters the scrubber tower 20 through the upper air blowing device, and enters the gas cabinet after recovering the sensible heat.

[0021] The upward blowing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com