Electrophoresis coating process for automobile part

An auto parts, electrophoretic coating technology, applied in electrophoretic coatings, metal material coating technology, electrolytic coatings, etc. Good temperature variability and good rust resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

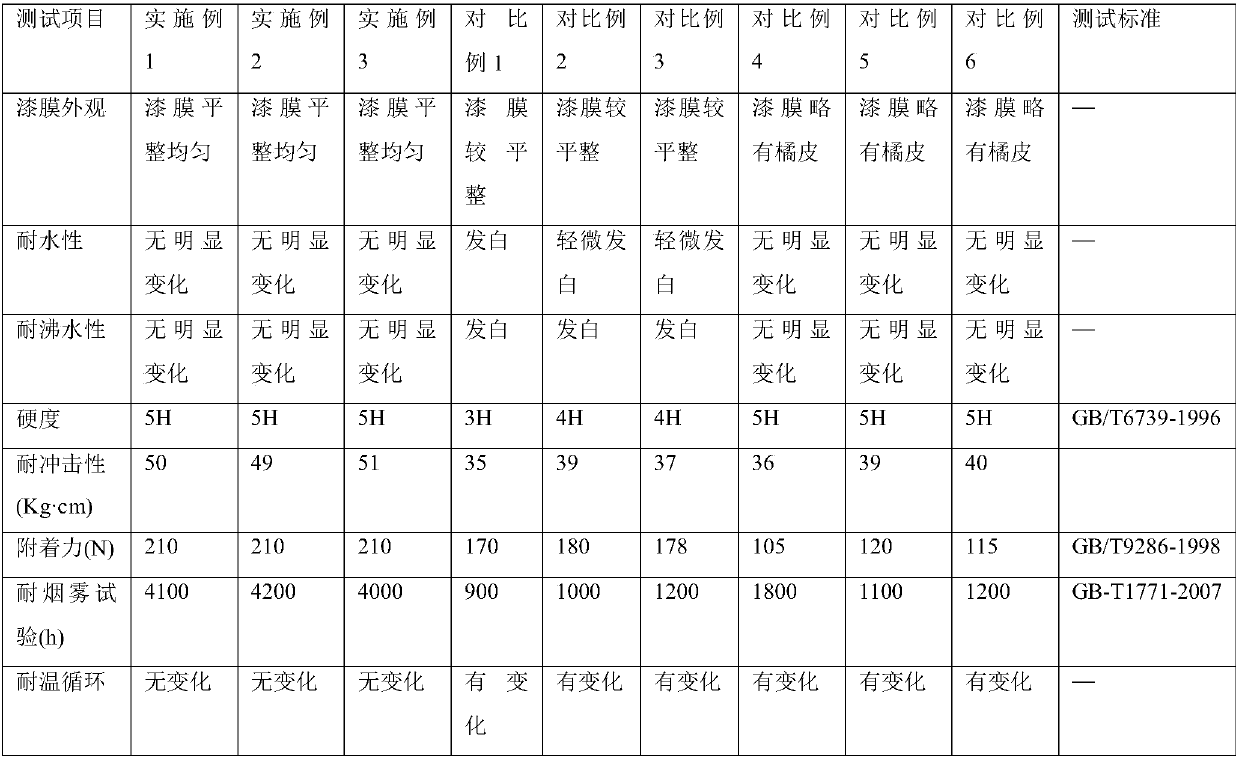

Embodiment 1

[0036]Preparation of silicon-fluorine modified cationic acrylic resin: under nitrogen atmosphere and stirring conditions, 20g propylene glycol methyl ether and 10g methyl methacrylate were mixed, and then added to the mixture of propylene glycol methyl ether and methyl methacrylate monomer At the same time, 20g of acrylate monomer (2g of butyl acrylate, 2g of isobornyl methacrylate, 4g of hydroxyethyl methacrylate, 6g of dimethylaminoethyl methacrylate and 6g of N-(isobutoxy) methyl Acrylic acid amide) and the mixture of 5g azobisisobutyronitrile and the mixture of 5g vinyltripropoxysilane and 5g perfluoropropyl ethyl methacrylate, the dropping temperature is 95 ℃, and the dropping time is 3 hours After the dropwise addition, 10g of propylene glycol methyl ether and 1g of azobisisobutyronitrile were added, the temperature was raised to 100°C, and then kept for 2h. After the reaction, the temperature was lowered to 65°C, and the pH was adjusted to 5~ 6. Obtain silicon-fluorine ...

Embodiment 2

[0049] Preparation of silicon-fluorine modified cationic acrylic resin: under nitrogen atmosphere and stirring conditions, 20g propylene glycol methyl ether and 13g methyl methacrylate were mixed, and then added to the mixture of propylene glycol methyl ether and methyl methacrylate monomer At the same time, 25g acrylate monomer (2.5g butyl acrylate, 2.5g isobornyl methacrylate, 5g hydroxyethyl methacrylate, 7.5g dimethylaminoethyl methacrylate and 7.5g N-(isobutoxy Base) methacrylic acid amide) and the mixture of 5g azobisisobutyronitrile and the mixture of 3g vinyltripropoxysilane and 4.5g perfluoropropyl ethyl methacrylate, the dropping temperature is 95 ℃, drop The addition time is 3 hours. After the dropwise addition, 5g of propylene glycol methyl ether and 1.5g of azobisisobutyronitrile are added. The temperature is raised to 100°C, and then kept for 2h. After the reaction is completed, the temperature is lowered to 65°, and added Lactic acid is used to adjust the pH to ...

Embodiment 3

[0062] Preparation of silicon-fluorine modified cationic acrylic resin: under nitrogen atmosphere and stirring conditions, 20g propylene glycol methyl ether and 15g methyl methacrylate were mixed, and then added to the mixture of propylene glycol methyl ether and methyl methacrylate monomer At the same time, 22g acrylate monomer (2.2g butyl acrylate, 2.2g isobornyl methacrylate, 4.4g hydroxyethyl methacrylate, 6.6g dimethylaminoethyl methacrylate and 6.6gN-(isobutyl Oxygen) methacrylic acid amide) and the mixture of 5g azobisisobutyronitrile and the mixture of 6g vinyltripropoxysilane and 3g perfluoropropyl ethyl methacrylate, the dropping temperature is 95 ℃, drop The addition time is 3 hours. After the dropwise addition, 7.5g of propylene glycol methyl ether and 2g of azobisisobutyronitrile are added. The temperature is raised to 100°C, and then kept for 2h. After the reaction is completed, the temperature is lowered to 65°, and added Lactic acid is used to adjust the pH to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com