Anion solid wood composite floor

A technology of solid wood composite floor and negative ions, which is applied in the joining of wooden veneers, wood processing appliances, construction and other directions, can solve the problems of scarring and uneven flatness, and can not solve the problems of floor deformation and difficult to meet, etc. Achieve the effect of stable product structure, good cushioning performance and avoid floor deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

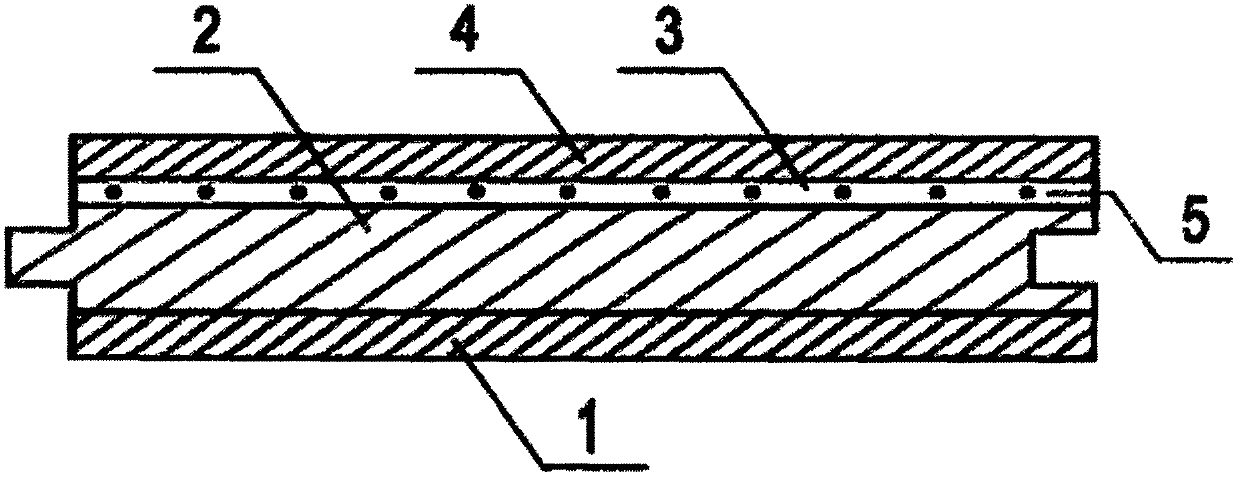

[0030] This embodiment is a four-layer structure, such as figure 1 shown.

[0031] Backplane 1 is selected as balanced film paper.

[0032] The core board 2 is selected as a poplar multilayer board.

[0033] Preparation of negative ion impregnated fiber layer 3: select the 0.4mm thick plant fiber paper produced by the three leftovers as the base layer, and prepare it in the adhesive containing negative ion powder 5 through one dipping and one drying. The specific steps are: The plant fiber paper is dipped once, and the dipping amount is 130% of the mass fraction of the plant fiber paper, wherein the anion powder 5 is evenly mixed into the adhesive, and the amount of the anion powder 5 is 12% of the mass fraction of the adhesive; then drying, drying temperature 140°C, drying time 46s, the pre-curing degree after drying is 38%; then cool to room temperature, cut, inspect, pack, and complete the preparation; the adhesive is selected as melamine resin adhesive; the negative ion ...

Embodiment 2

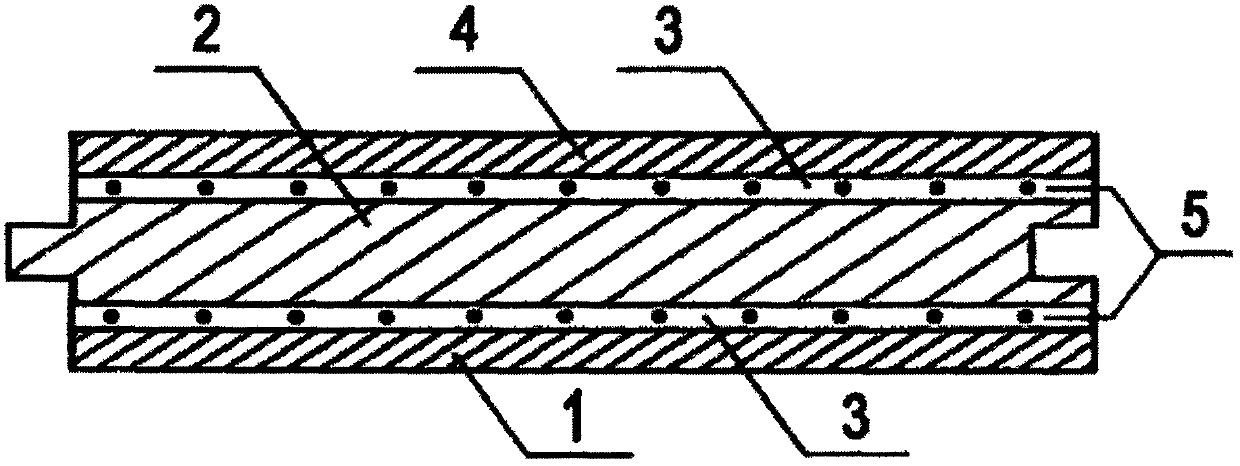

[0040] This embodiment is a five-layer structure, such as figure 2 shown.

[0041] The backboard 1 is selected as the eucalyptus veneer.

[0042] The core board 2 is selected as a poplar multilayer board.

[0043] The preparation of negative ion impregnated fiber layer 3, selects the thick non-woven fabric of 0.6mm as the base layer, it is prepared by dipping twice and drying twice in the adhesive containing negative ion powder, the specific steps are as follows:

[0044] A, first dipping the non-woven fabric for the first time, the dipping amount is 85% of the mass fraction of the non-woven fabric, wherein the anion powder 5 is evenly mixed into the adhesive, and the amount of the anion powder 5 is 15% of the mass fraction of the adhesive %, adhesive is selected as urea-formaldehyde resin modified adhesive, negative ion powder 5 is selected as 1000 purpose tourmaline powder and hexacyclic stone powder mixture (mass ratio 6: 4);

[0045] B. Then carry out the first drying,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com