A method for preparing complex high-strength aluminum alloys using laser-induced arc additive manufacturing technology

A laser-induced and additive manufacturing technology, applied in the field of additive manufacturing, can solve problems affecting the performance of parts, low dimensional accuracy, composition segregation, etc., and achieve the effects of suppressing cracks, improving forming quality, and shortening the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

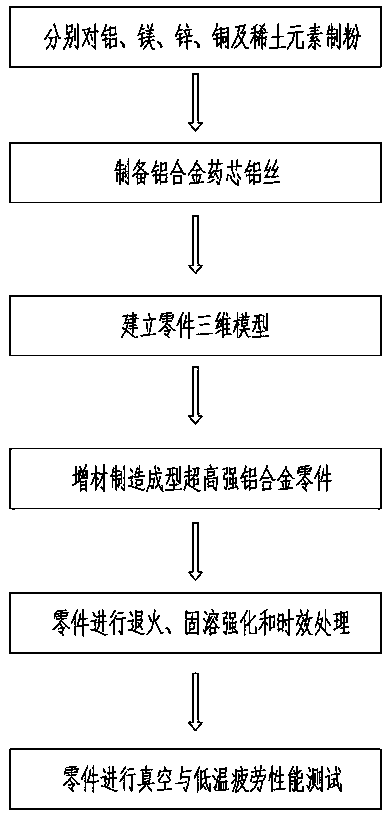

Image

Examples

Embodiment 1

[0032] A method for preparing complex high-strength aluminum alloys using laser-induced arc additive manufacturing technology in this embodiment includes the following steps:

[0033] (1) In an argon environment, aluminum, magnesium, zinc, and copper are pulverized by atomization pulverization method to obtain aluminum powder, magnesium powder, zinc powder and copper powder respectively, and then the rare earth elements zirconium and scandium are pulverized. Mixing and milling to obtain rare earth powder;

[0034] (2) Mix according to the mass fractions of aluminum powder, magnesium powder, zinc powder, copper powder and rare earth powder to be 85.1%, 3.3%, 8.3%, 2.3% and 1.0% respectively to obtain alloy powder; Shaped high-strength aluminum alloy is rolled into a hollow tubular shape, and the alloy powder is filled into the tube core of the tubular high-strength aluminum alloy to obtain an aluminum alloy flux-cored aluminum wire, and the diameter of the aluminum alloy flux-c...

Embodiment 2

[0048] A method for preparing complex high-strength aluminum alloys using laser-induced arc additive manufacturing technology in this embodiment includes the following steps:

[0049] (1) In an argon environment, aluminum, magnesium, zinc, and copper are pulverized by atomization pulverization method to obtain aluminum powder, magnesium powder, zinc powder and copper powder respectively, and then the rare earth elements zirconium and scandium are pulverized. Mixing and milling to obtain rare earth powder;

[0050] (2) According to the mass fraction of aluminum powder, magnesium powder, zinc powder, copper powder and rare earth powder are respectively 84.6%, 3.3%, 8.3%, 2.3% and 1.5%, the alloy powder is obtained; Shaped high-strength aluminum alloy is rolled into a hollow tubular shape, and the alloy powder is filled into the tube core of the tubular high-strength aluminum alloy to obtain an aluminum alloy flux-cored aluminum wire, and the diameter of the aluminum alloy flux-c...

Embodiment 3

[0064] A method for preparing complex high-strength aluminum alloys using laser-induced arc additive manufacturing technology in this embodiment includes the following steps:

[0065] (1) In an argon environment, aluminum, magnesium, zinc, and copper are pulverized by atomization pulverization method to obtain aluminum powder, magnesium powder, zinc powder and copper powder respectively, and then the rare earth elements zirconium and scandium are pulverized. Mixing and milling to obtain rare earth powder;

[0066] (2) Mix according to the mass fractions of aluminum powder, magnesium powder, zinc powder, copper powder and rare earth powder to be 84.1%, 3.3%, 8.3%, 2.3% and 2.0% respectively to obtain alloy powder; Shaped high-strength aluminum alloy is rolled into a hollow tubular shape, and the alloy powder is filled into the tube core of the tubular high-strength aluminum alloy to obtain an aluminum alloy flux-cored aluminum wire. The diameter of the aluminum alloy flux-cored...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com