Preparation method of 2,3,5-trichloropyridine

A technology of trichloropyridine and tetrachloropyridine, which is applied in the field of preparation of 2,3,5-trichloropyridine, achieves the effects of short reaction time, non-corrosion, and reduced treatment cost of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

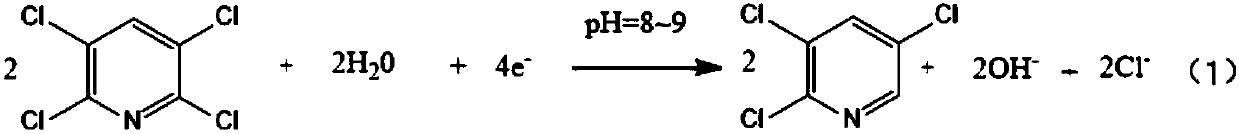

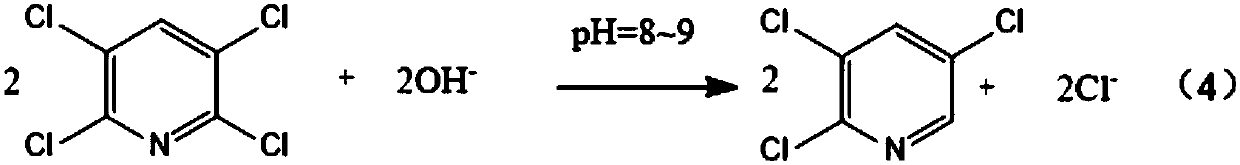

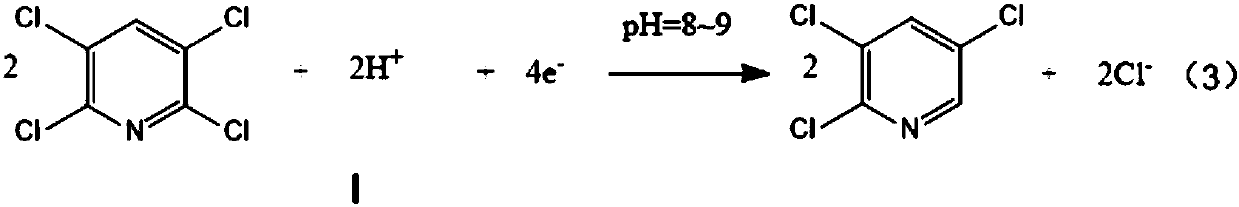

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The diaphragm plate frame tank is an electrolytic reactor, the perfluorosulfonic acid membrane is a diaphragm, the lead sheet is a cathode, and the graphite plate is an anode. 1000mL 0.1mol / L 2,3,5,6-tetrachloropyridine (TeCP) (21.8g, GC content 99.1%)+0.3mol / L NH 4 The methanol solution of Cl (16.2g) + 1% vol ammonia water (ammonia content 25% ~ 28%) + 9% vol water is the catholyte; 1000mL0.1mol / L sodium hydroxide aqueous solution is the anolyte. During the electrolysis process, the temperature is controlled at 45-50°C, and the current density is controlled at 3A / dm 2 , the initial pH of catholyte=8. Stop electrolysis after electrifying for 4.2h (that is, a theoretical electric quantity Q*). GC analysis of the catholyte showed:

[0054] 3,5-Dichloropyridine: 7.671%

[0055] 2,5-Dichloropyridine: 4.238%

[0056] 2,3,5-Trichloropyridine: 60.46%

[0057] 2,3,6-Trichloropyridine: 5.152%

[0058] 2,3,5,6-Tetrachloropyridine: 21.38%

[0059] After distilling the cath...

Embodiment 2

[0062] Same operation with embodiment 1, but change anolyte sodium hydroxide concentration into 0.15mol / L, the GC analysis of catholyte shows:

[0063] 3,5-Dichloropyridine: 5.405%

[0064] 2,5-Dichloropyridine: 3.139%

[0065] 2,3,5-Trichloropyridine: 56.91%

[0066] 2,3,6-Trichloropyridine: 5.143%

[0067] 2,3,5,6-Tetrachloropyridine: 28.46%

[0068] The products obtained by the comprehensive treatment of the reaction solution are respectively:

[0069] 0.99g of 3,5-dichloropyridine, 0.66g of 2,5-dichloropyridine, 12.11g of 2,3,5-trichloropyridine, 1.03g of 2,3,6-trichloropyridine and unreacted 2,3 , 5,6-tetrachloropyridine 5.96g, in summary, the yield of 2,3,5-trichloropyridine is 55.55%.

Embodiment 3

[0071] Same operation as embodiment 1, but ammoniacal liquor is changed into triethylamine, and the GC analysis of catholyte shows:

[0072] 3-chloropyridine: 5.498%

[0073] 2,5-Dichloropyridine: 3.452%

[0074] 2,3,5-Trichloropyridine: 70.24%

[0075] 2,3,6-Trichloropyridine: 5.795%

[0076] 2,3,5,6-Tetrachloropyridine: 14.43%

[0077] The products obtained by the comprehensive treatment of the reaction solution are respectively:

[0078] 0.83g of 3-chloropyridine, 0.58g of 2,5-dichloropyridine, 14.43g of 2,3,5-trichloropyridine, 1.02g of 2,3,6-trichloropyridine and unreacted 2,3,5, 3.06 g of 6-tetrachloropyridine. In summary, the yield of 2,3,5-trichloropyridine is 66.19%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com