Multifunctional reaction tank

A multi-functional, reaction tank technology, applied in chemical/physical/physical-chemical stationary reactors, plant raw materials, mixers, etc., can solve the problems of difficult market requirements and high production costs of artemisia gum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

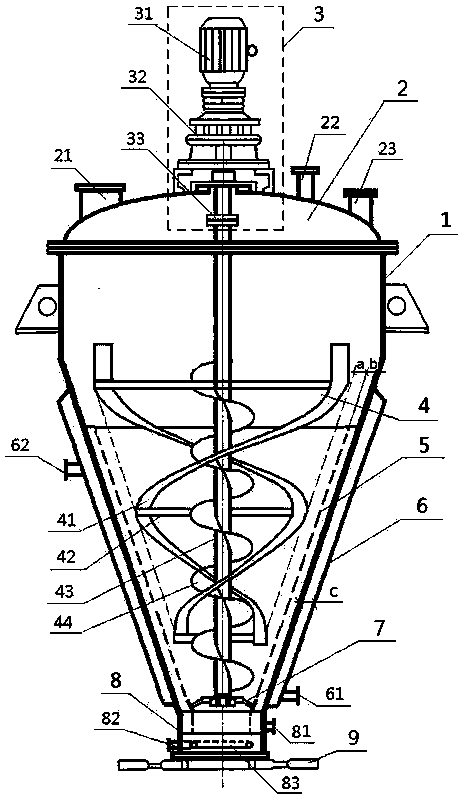

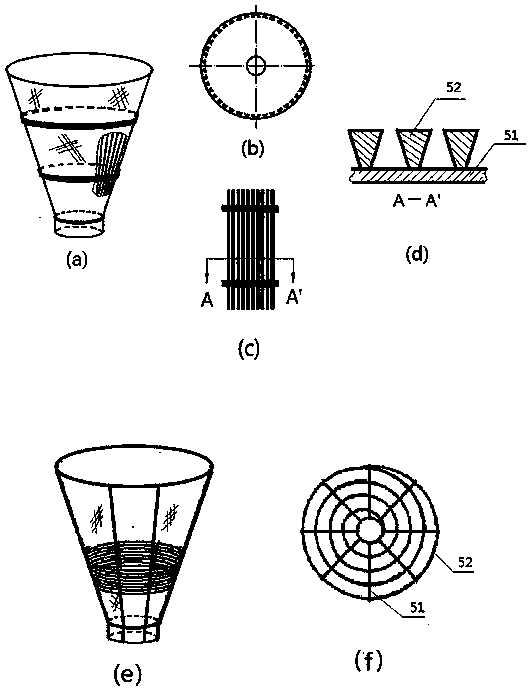

[0018] figure 1 A specific composition of the multifunctional reaction tank of the present invention is given. It includes a tank body 1, an upper sealing head 2, a driver 3, an agitator 4, a built-in filter screen 5, a heating jacket 6, a shaft frame 7, a lower sealing head 8 and a discharge valve 9.

[0019] The tank body 1 is a cone-shaped pressure vessel made of stainless steel coils, with a pressure resistance of not less than 0.2 MPa. Its upper half is a cylinder and the lower half is a cone. A heating jacket 6 is arranged outside the tank body 1, and an agitator 4, a shaft frame 7, and a built-in filter screen 5 are arranged inside the tank body 1; The lower end of the head is connected to the discharge valve 9 through a flange.

[0020] The upper head 2 is an arc-shaped head, which has the advantage of high compressive strength and can increase the volume ratio of the tank. The upper head 2 is provided with a feeding port 21, a condensation port 22, and a pressure ...

Embodiment 2

[0032] Using the multifunctional reaction tank of Example 1 of the present invention to prepare Artemisia gum, the specific production process is as follows.

[0033] 1) Put 300Kg of Artemisia sativa seed raw material and 450Kg of 75% edible alcohol preheated to 65°C-75°C and 10Kg of degumming agent into reaction tank 1 through feed port 21, and the reaction tank conducts heat through heating jacket 6 The oil temperature is controlled at about 75°C.

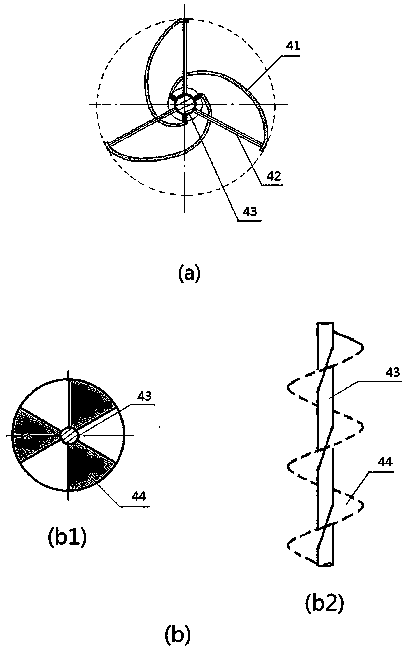

[0034] 2) Start the motor 31, drive the agitator 4 to perform strong mixing and shearing friction at 65rmp / min on the materials in the tank, and at the same time, enter compressed air from the intake pipe 82 of the lower head 8 to remove the materials deposited at the bottom of the tank Floating up, under the dual agitation and friction of pneumatic agitation and mechanical agitation, the raw materials and the degumming agent undergo rapid and homogeneous mass transfer and heat transfer, and the degumming reaction is completed in...

Embodiment 3

[0038] Using the multi-functional reaction tank of Example 1 of the present invention, the specific production process for preparing the Artemisia Artemisiae oil product is as follows.

[0039] About 220kg of the Artemisia artemisia seed meal degummed in Example 2 is discharged out of the tank after pre-drying and desolventizing, and is subjected to tableting or puffing treatment, and then mixed with petroleum ether or n-hexane with an equivalent distillation range of 65°C-90°C (light gasoline) together into the reaction tank, leaching at room temperature for 1-2 hours, solid-liquid separation is carried out through the built-in filter 5, and the mixed oil is discharged from the liquid outlet 81 for further refining into Artemisia oil; degreased material The meal is discharged out of the tank from the discharge valve 9 after passing into the steam drying from the air inlet 82, and is used for further production of artemisia protein powder, or as animal feed. The solvent vapor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com