Nitrogen-doped mesoporous -carbon-wrapped titanium dioxide composite photocatalyst as well as preparation method and application thereof

A nitrogen-doped mesoporous carbon, titanium dioxide technology, applied in catalyst activation/preparation, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc., can solve the problem of VOCs reducing photocatalytic efficiency, sunlight Low utilization rate and other problems, to achieve the effect of efficient solar photocatalytic degradation of VOCs, improved catalytic activity and stability, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

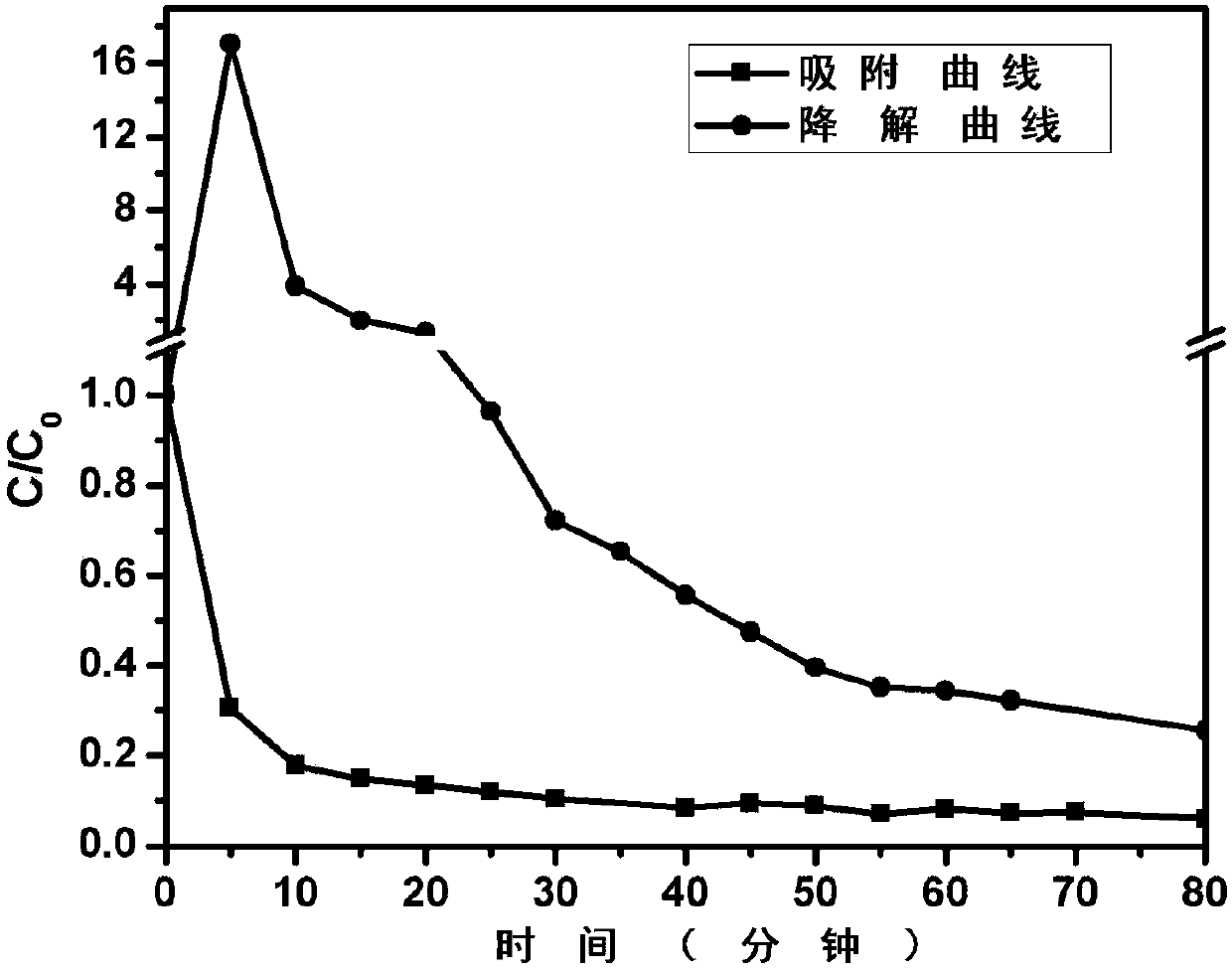

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Photocatalytic material preparation

[0032] S1. 2-aminoterephthalic acid, Ti(OC) with a molar ratio of 3:2:23:118 3 h 7 ) 4 , methanol and DMF are mixed and then added to the reaction kettle with polytetrafluoroethylene;

[0033] S2. Place the reaction kettle in an oven, set the program, raise it to 150°C at a rate of 1°C / min, then keep it for 48h, and lower it to room temperature at a rate of 5°C / h to obtain a precipitate;

[0034]S3. Cross-washing the precipitate obtained in step S2 with methanol and DMF, centrifuging, and vacuum drying at 150° C. for 12 hours to obtain an activated titanium-based MOFs material;

[0035] S4. Put an appropriate amount of the activated titanium-based MOFs material prepared in step S3 into a tube furnace, raise it from room temperature to 600° C. at a rate of 1° C. / min under an Ar atmosphere, and keep it at this temperature for 6 hours; then Replace Ar with CO when cooling down to 500°C at a rate of 1°C / min 2 , and keep it for 3...

Embodiment 2

[0039] S1. A mixture of 2-aminoterephthalic acid and terephthalic acid with a molar ratio of 3:2:23:118, Ti(OC 3 h 7 ) 4 , methanol and DMF are mixed and then added to the reaction kettle with polytetrafluoroethylene;

[0040] S2. Put the reaction kettle in an oven, set the program, raise it to 150°C at a rate of 5°C / min, then keep it for 72h, and lower it to room temperature at a rate of 5°C / h to obtain a precipitate;

[0041] S3. The precipitate obtained in step S2 is cross-washed with methanol and DMF, centrifuged, and then vacuum-dried at 120° C. for 24 hours to obtain an activated titanium-based MOFs material;

[0042] S4. Put an appropriate amount of the catalyst prepared in step S3 into a tube furnace, raise the temperature from room temperature to 700° C. at a rate of 2° C. / min under an Ar atmosphere, and keep it at this temperature for 7 hours; Nitrogen-doped mesoporous carbon-wrapped TiO can be prepared by lowering the rate at room temperature 2 composite photoca...

Embodiment 3

[0044] S1. 2-aminoterephthalic acid, Ti(OC) with a molar ratio of 3:2:23:118 3 h 7 ) 4 , methanol and DMF are mixed and then added to the reaction kettle with polytetrafluoroethylene;

[0045] S2. Put the reaction kettle in an oven, set the program, raise it to 150°C at a rate of 1°C / min, then keep it for 48 hours, and lower it to room temperature at a rate of 5°C / h to obtain a precipitate;

[0046] S3. The precipitate obtained in step S2 is cross-washed with methanol and DMF, centrifuged, and then vacuum-dried at 150° C. for 8 hours to obtain an activated titanium-based MOFs material;

[0047] S4. Put an appropriate amount of the catalyst prepared in step S3 into a tube furnace, raise the temperature from room temperature to 500° C. at a rate of 3° C. / min under an Ar atmosphere, and keep this temperature for 9 hours; When the rate of min drops to 300°C, Ar is replaced by CO 2 , keep for 60min; finally switch back to the Ar atmosphere, and continue to cool down to room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com