Method and device for preparing diphenylmethane series diamine and polyamine with low N-methyl impurity content and catalyst

A technology of diphenylmethane and catalyst, applied in the field of diphenylmethane series di- and polyamines, to achieve the effects of reducing content, improving product quality, and increasing reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

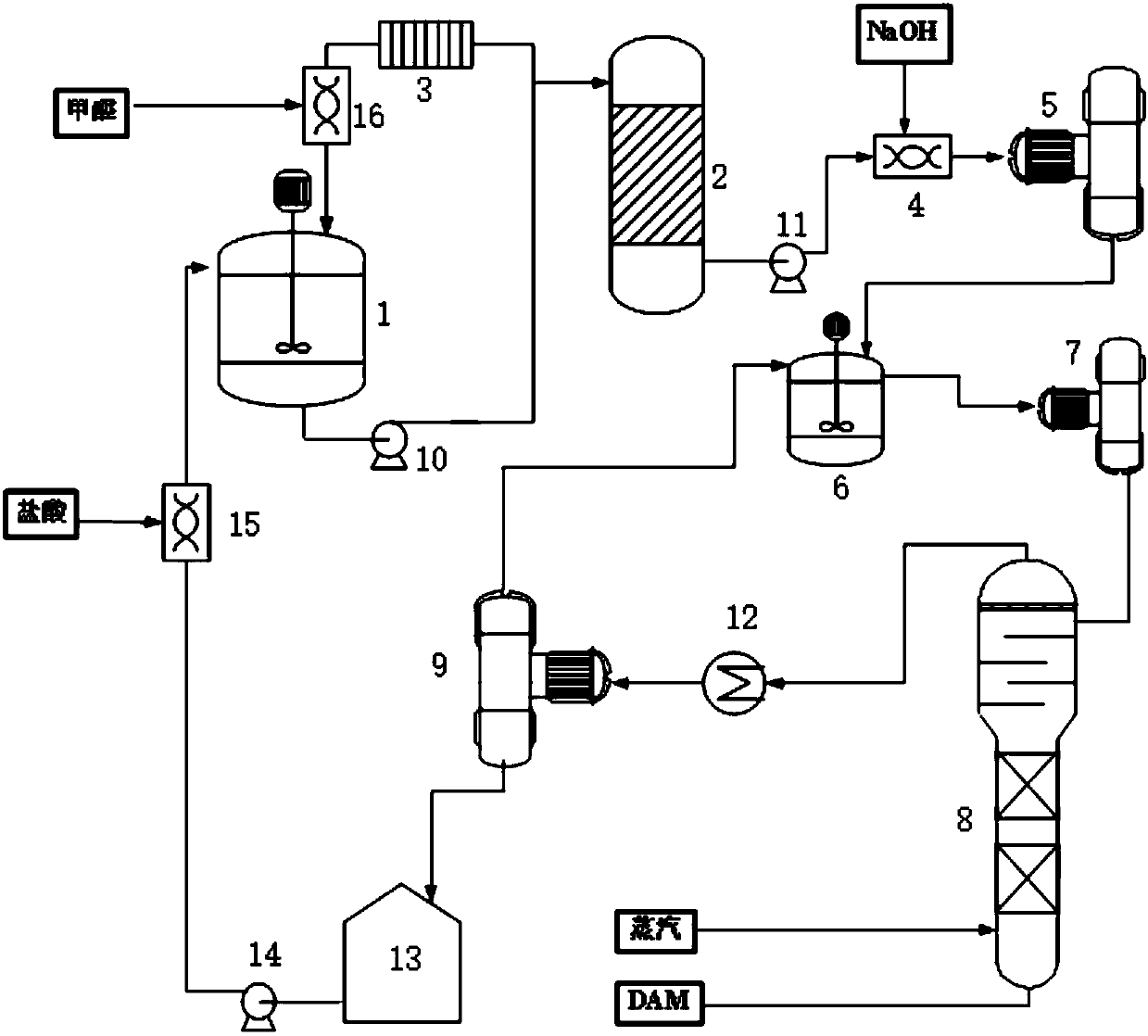

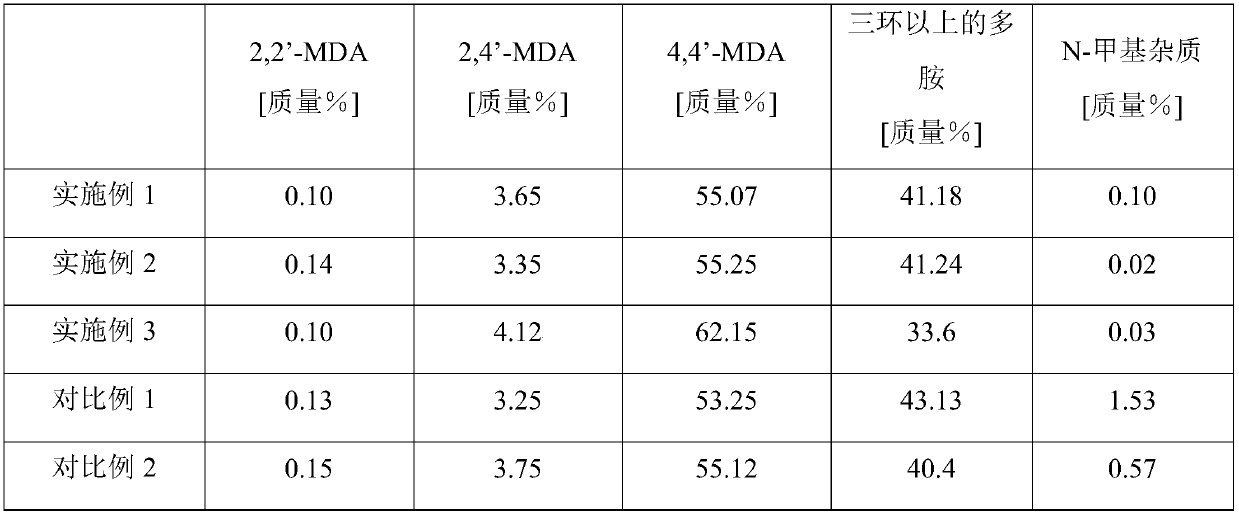

[0044] The reaction process is as figure 1 As shown in the process flow chart, the active component of the transposition rearrangement reaction catalyst vanadium phosphate oxide carrier is γ-Al 2 o 3 , aniline material (mass concentration is 94%) and formaldehyde material (formaldehyde mass concentration is 37%) enters condensation reactor 1, and the mol ratio of hydrochloric acid and aniline is 0.41:1, and formaldehyde and aniline mol ratio are 0.60:1, residence time Are 60min, the condensation reaction occurred. A reaction mixture containing polyaminobenzylaniline salt is generated, which enters a vanadium phosphate oxide catalyst (supported on γ-Al 2 o 3 , based on the metal element, the mass fraction of the active component of the catalyst is 0.01%, and the vanadium phosphate oxide is prepared by roasting a mixture of vanadium pentoxide and phosphoric acid, and the mass ratio of the raw materials is 1:3). In the fixed-bed reactor 2, the catalyst Transposition rearrange...

Embodiment 2

[0046] The reaction process is as figure 1 As shown in the process flow diagram, the transposition rearrangement reaction catalyst active component Pr 2 o 3 -Ce 2 o 3 The solid solution carrier is γ-Al 2 o 3 , aniline material (mass concentration is 94%) and formaldehyde material (formaldehyde mass concentration is 37%) enters condensation reactor 1, and the mol ratio of hydrochloric acid and aniline is 0.41:1, and formaldehyde and aniline mol ratio are 0.60:1, residence time Are 60min, the condensation reaction occurred. A reaction mixture containing polyaminobenzylaniline salt is generated, which is filled with Pr 2 o 3 -Ce 2 o 3 Solid solution catalyst (Pr 2 o 3 50%, Ce 2 o 3 50%, supported on γ-Al 2 o 3 , on the basis of metal element, the mass fraction of catalyst active components is 0.05%, Pr 2 o 3 -Ce 2 o 3 The solid solution is prepared by the co-precipitation method, the co-precipitation agent is NaOH, and the active component is loaded on the car...

Embodiment 3

[0048] The reaction process is as figure 1 As shown in the process flow chart, the active component of the transposition rearrangement reaction catalyst is Nb 2 o 5 -La 2 o 3 Solid solution, the carrier is γ-Al 2 o 3 , aniline material (mass concentration is 94%) and formaldehyde material (formaldehyde mass concentration is 37%) enters condensation reactor 1, and the mol ratio of hydrochloric acid and aniline is 0.21:1, and formaldehyde and aniline mol ratio are 0.40:1, residence time Are 60min, the condensation reaction occurred. A reaction mixture containing polyaminobenzylaniline salt is generated, which enters the Nb-filled 2 o 5 -La 2 o 3 Solid solution (Nb 2 o 5 50% by mass, La 2 o 3 50% by mass, loaded on γ-Al 2 o 3, on the basis of metal element, the mass fraction of catalyst active components is 0.05%, Nb 2 o 5 -La 2 o 3 The solid solution is prepared by the co-precipitation method, the co-precipitation agent is NaOH, and the active component is lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com