Modification method for improving electrochemical performance of lithium-rich manganese-based material

A lithium-rich manganese-based, electrochemical technology, applied in the direction of circuits, electrical components, battery electrodes, etc., can solve undesirable and inefficient problems, achieve high electronic conductivity and lithium ion diffusion rate, high efficiency, and tight integration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

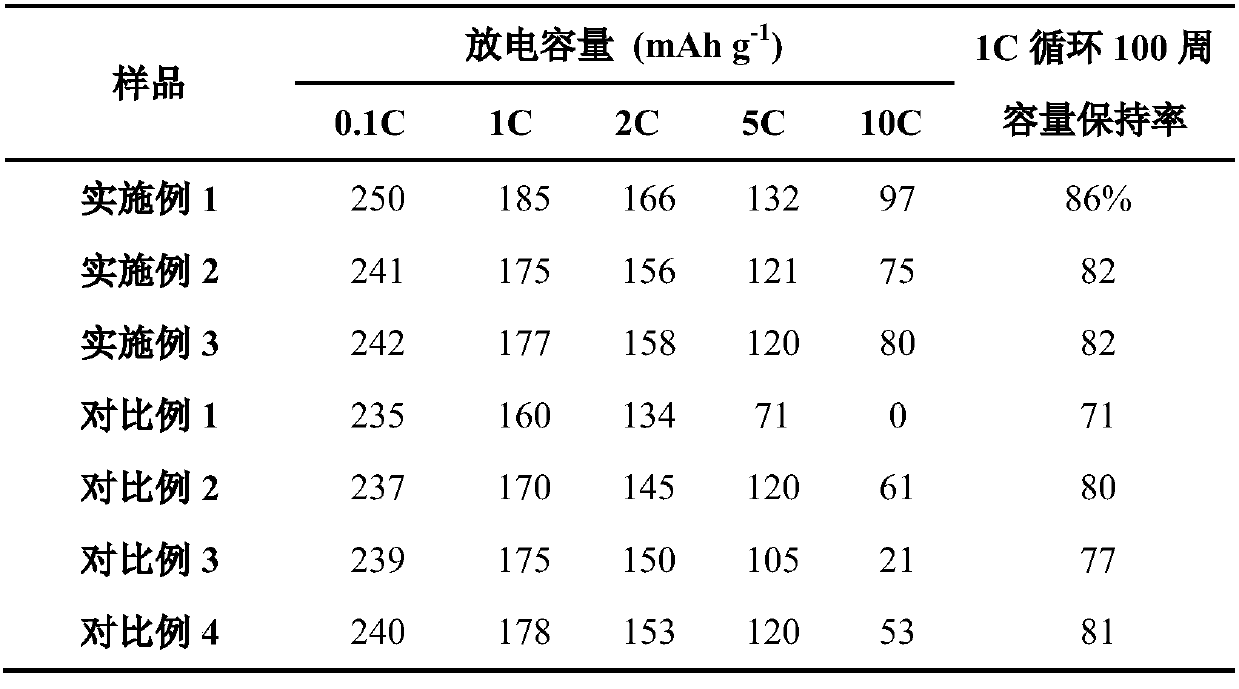

Examples

preparation example Construction

[0039] At the same time, the present invention provides a method for preparing the above-mentioned lithium-ion battery lithium-rich manganese-based material positive electrode with a comprehensive three-dimensional conductive network, which includes: two parts for preparing the three-dimensional conductive network between the active materials of the positive electrode material and the conductive network of the current collector, including the following steps:

[0040]Step 1: The preparation of the three-dimensional conductive network between the active materials of the positive electrode material, as an optimization, there are two methods:

[0041] the first method:

[0042] (1) Disperse one or more of the above-mentioned certain amount of graphene, carbon nanotubes, carbon fiber materials and lithium-rich manganese-based materials in a solvent, and disperse them ultrasonically for 5-60 minutes;

[0043] (2) Add the obtained conductive agent solution dropwise into the lithium-...

Embodiment 1

[0057] Example 1: A modified preparation for improving the rate performance of lithium-rich manganese-based materials

[0058] The positive electrode sheet includes: a current collector, a conductive network coated on the current collector, and an active material with a three-dimensional conductive network.

[0059] The current collector is a common commercial aluminum foil;

[0060] The surface conductive network of the current collector is composed of 1 part of PVDF and 20 parts of graphene;

[0061] The active material coating consists of 75 parts lithium-rich manganese-based material Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 , 2.5 parts of graphene, 2.5 parts of carbon nanotubes, 10 parts of SP, and 10 parts of PVDF.

[0062] The preparation method is as follows:

[0063] (1) Disperse the weighed graphene, carbon nanotubes and lithium-rich manganese-based materials in ethanol, and disperse them ultrasonically for 30 minutes;

[0064] (2) Graphene solution is added dropwis...

Embodiment 2

[0071] The positive electrode sheet includes: a current collector, a conductive network coated on the current collector, and an active material with a three-dimensional conductive network.

[0072] The current collector is a common commercial aluminum foil;

[0073] The surface conductive network of the current collector is composed of 1 part of PVDF and 20 parts of graphene;

[0074] The active material coating consists of 75 parts lithium-rich manganese-based material Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 , 5 parts of graphene, 10 parts of SP, 10 parts of PVDF.

[0075] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com