Particle spacing control method for ordered precious metal nano-particle array

A nanoparticle array and control method technology is applied in the field of particle spacing control of ordered noble metal nanoparticle arrays, and can solve problems such as inability to accurately design the spacing between adjacent particles of the array and obstacles to noble metal nanoparticle arrays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for controlling the particle spacing of an ordered noble metal nanoparticle array, comprising the steps of:

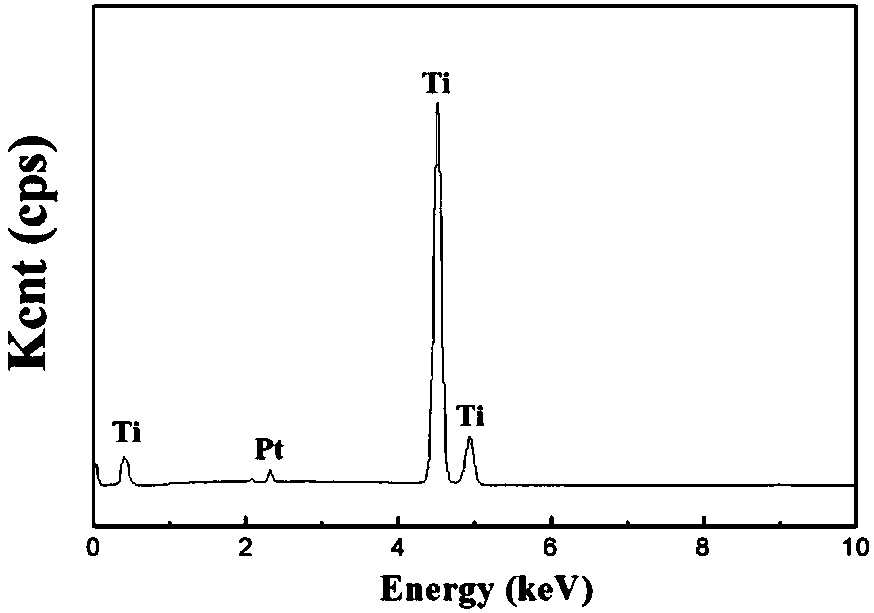

[0046] 1) Diblock copolymer template method to implant the initial ordered array of platinum nanoparticles

[0047] Add solid chloroplatinic acid to the PS-b-P4VP spherical micelles / tetrahydrofuran solution at a molar ratio of chloroplatinate to pyridine of 1:8, magnetically stir at a rotor speed of 400 rpm for 6 hours at room temperature, and prepare a platinum content of 0.125 mg / ml of precursor / copolymer THF solution.

[0048] A titanium sheet with a size of 10mm*10mm and a thickness of 0.2mm was pickled in hydrochloric acid with a mass fraction of 10% at 80°C for 10min, and then rinsed several times with deionized water. The titanium sheets after pickling were polished with No. 600, No. 1000, No. 2000 and No. 3000 metallographic sandpaper in sequence, and ultrasonically cleaned in absolute ethanol and deionized water for 10 min in sequence.

[00...

Embodiment 2

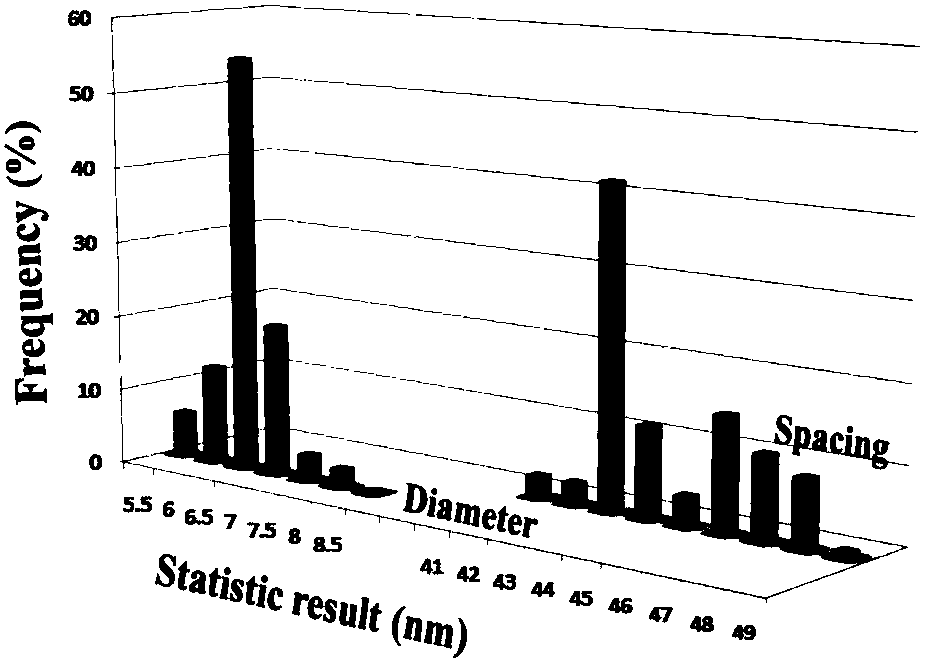

[0054] The steps are basically the same as those in Example 1, the only difference being that the total number of implants is designed to be S=9, so as to obtain an ordered array of platinum nanoparticles whose spacing is 1 / 3 times that of the initial array. After finishing the preparation, the calculated l n =14nm, in line with the design value, and the particle arrangement form and main particle diameter are consistent with the initial array, that is, when S=3 n , then the center-to-center distance l between adjacent particles in the ordered noble metal nanoparticle array n Satisfies the following formula: l n = l 0 / 3 n / 2 ,Such as Figure 3a with Figure 3b They are the photo of the morphology of the titanium-loaded ordered platinum nanoparticle array, the statistical results of the particle diameter and the center-to-center distance of adjacent particles, respectively.

Embodiment 3

[0056] The steps are basically the same as in Example 1, the only difference is that the total number of implants designed is S=27, so that the spacing is 1 / 3 of the initial array 3 / 2 times the ordered array of platinum nanoparticles. After finishing the preparation, the calculated l n =8nm, in line with the design value, and the particle arrangement and main particle diameter are consistent with the original array, Figure 4a with Figure 4b They are the photo of the morphology of the titanium-loaded ordered platinum nanoparticle array, the statistical results of the particle diameter and the center-to-center distance of adjacent particles, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com