Rotating electrode tube type electrochemical reactor and application thereof

A technology of rotating electrodes and reactors, used in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. Increase investment and other issues to achieve the effect of small footprint, small length and electrode area, and fast removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

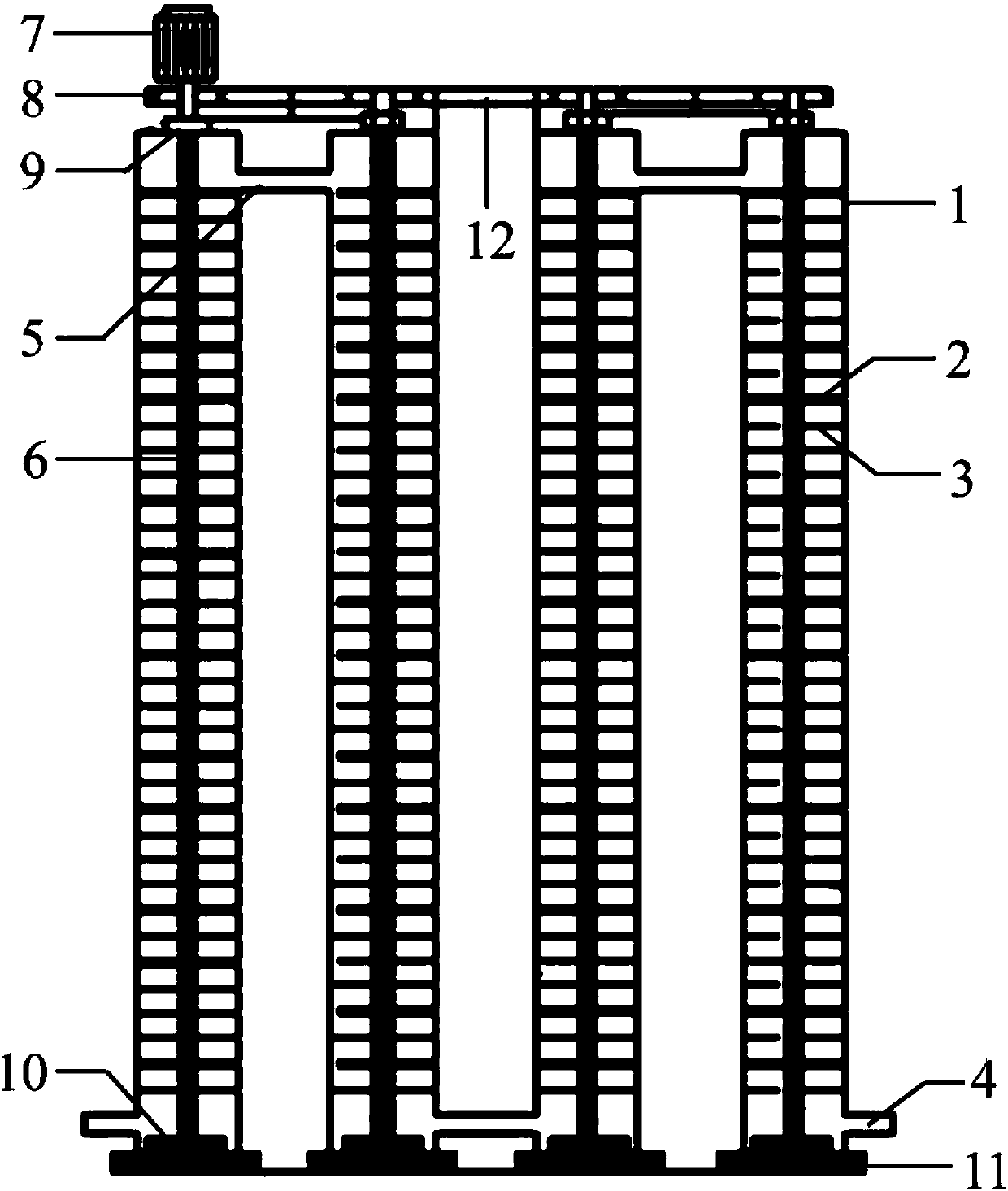

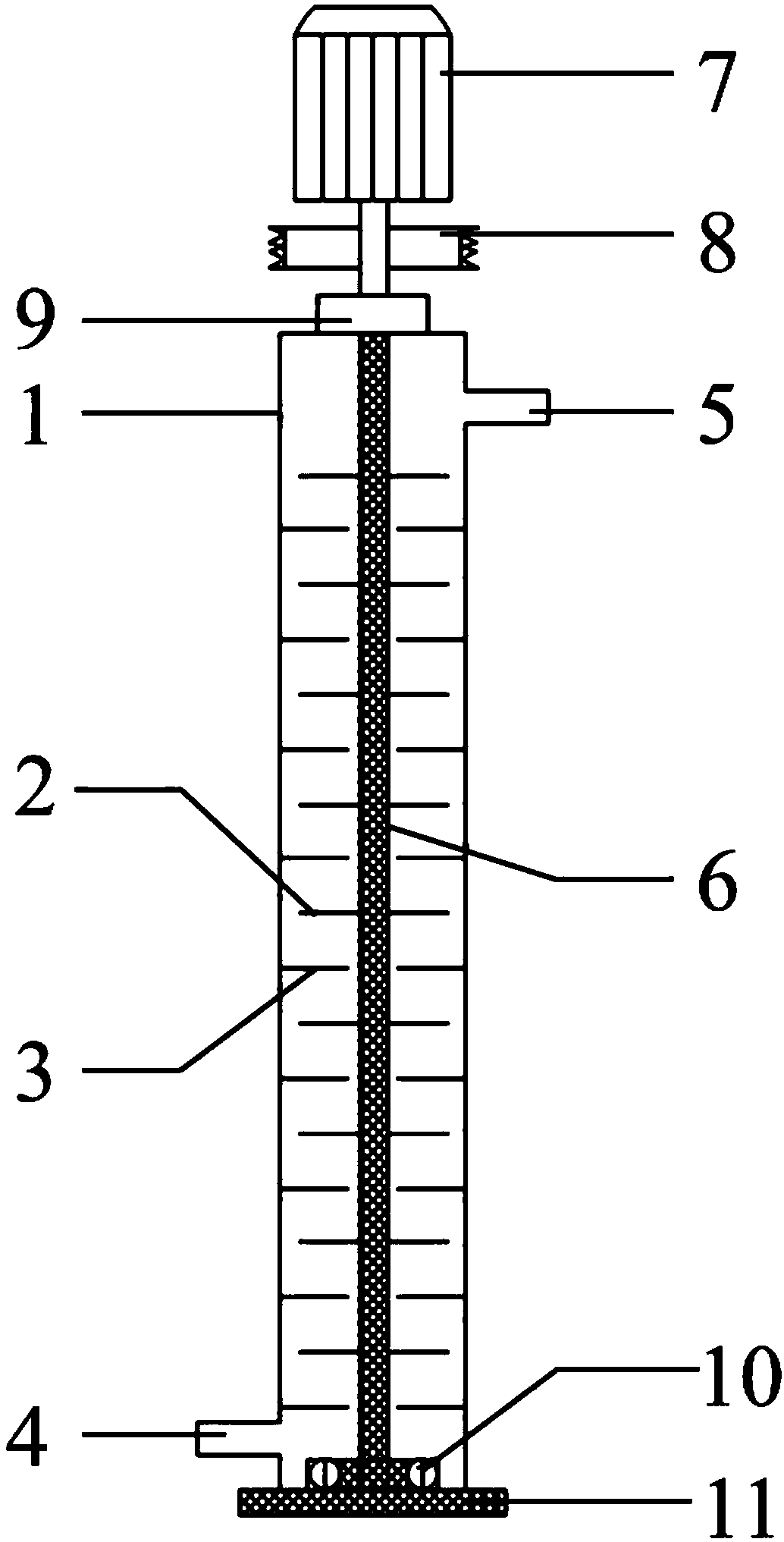

[0030] see figure 1 As shown, a rotating electrode electrochemical reactor includes an electrochemical reactor housing 1, a rotating anode 2, a stationary cathode 3, a rotating shaft 6, a motor 7, a conductive slip ring 9, and a bearing 10, and the electrochemical reactor housing 1 is a vertical tubular or vertical cylindrical body with an insulated inner wall. The electrochemical reactor housing 1 is provided with a liquid inlet 4 at the lower part and a liquid outlet 5 at the upper part; the rotating shaft 6 is longitudinally arranged on the electrochemical reactor housing 1, the upper end of the rotating shaft 6 passes through the top of the electrochemical reactor housing 1 and is connected to the output shaft of the motor 7, and the lower end of the rotating shaft 6 is fixedly arranged in the bearing 10 at the bottom of the electrochemical reactor housing 1; the rotating anode 2 is fixed on the rotating shaft 6, the static cathode 3 is fixed on the inner wall of the elect...

Embodiment 2

[0041] see figure 2 As shown, the four-stage rotating electrode tubular electrochemical reactor includes the first rotating electrode tubular electrochemical reactor, the second rotating electrode tubular electrochemical reactor, the third rotating electrode tubular electrochemical reactor, and the fourth rotating electrode tubular electrochemical reactor. Rotating electrode tubular electrochemical reactor; the output shaft of the motor of the first rotating electrode tubular electrochemical reactor is provided with a first transmission gear, the second rotating electrode tubular electrochemical reactor, the third rotating electrode The upper ends of the tubular electrochemical reactor and the fourth rotating electrode tubular electrochemical reactor are correspondingly provided with a second transmission gear, a third transmission gear and a fourth transmission gear. the second transmission gear, the third transmission gear and the fourth transmission gear;

[0042]The uppe...

Embodiment 3

[0044] Take the treatment of phenol-containing wastewater as an example.

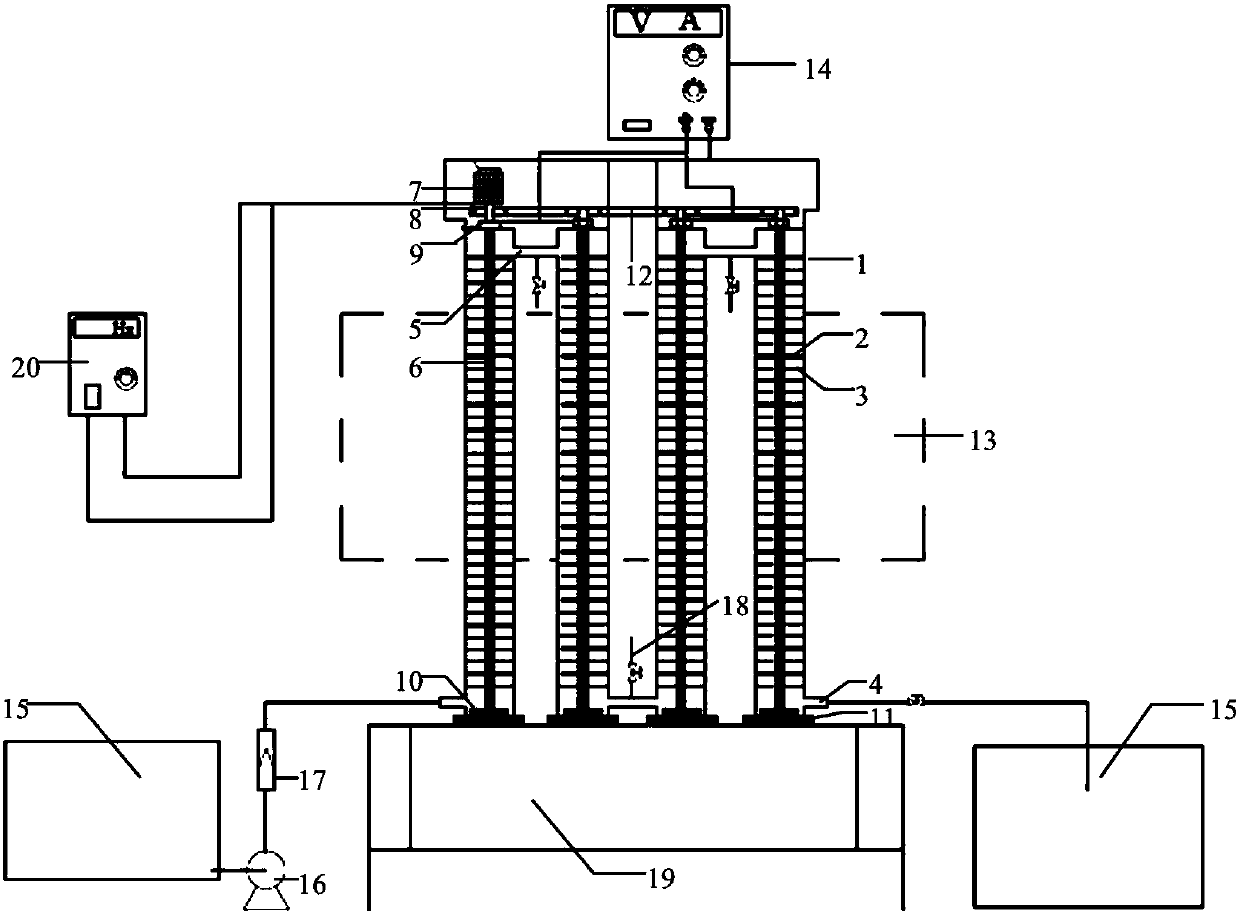

[0045] For the experimental apparatus used in this experiment, see image 3 As shown, it includes a reactor group 13 composed of four separate rotating electrode tubular electrochemical reactors, a single reactor shell 1, a rotating anode 2, a stationary cathode 3, a liquid inlet 4, a liquid outlet 5, and a rotating shaft 6 , motor 7, reaction shaft connection gear 8, conductive slip ring 9, bearing 10, reactor flange 11, transmission chain 12, DC regulated power supply 14, liquid storage tank 15, infusion pump 16, flow meter 17, sampling valve 18 , device support 19, frequency conversion instrument 20. Such as image 3 As shown, the reactor group 13 is connected by 4 separate rotating electrode electrochemical reactors, and all the rotating shafts 6 are driven to rotate through the transmission chain 12 connected with the gear 8; the shell of each reactor is 1000mm long and 100mm in diameter. The ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com