Silicon nitride-lithium niobate heterogeneous integrated waveguide device structure and preparation method of the same

An integrated waveguide and device structure technology, applied in the direction of optical waveguide light guide, light guide, instrument, etc., can solve the problems of incompatibility of semiconductor processing technology, limitation of large-scale batch production, difficulty of real-time monitoring of polishing process, etc., to achieve compact structure, The effect of compatible processing technology and high extinction ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

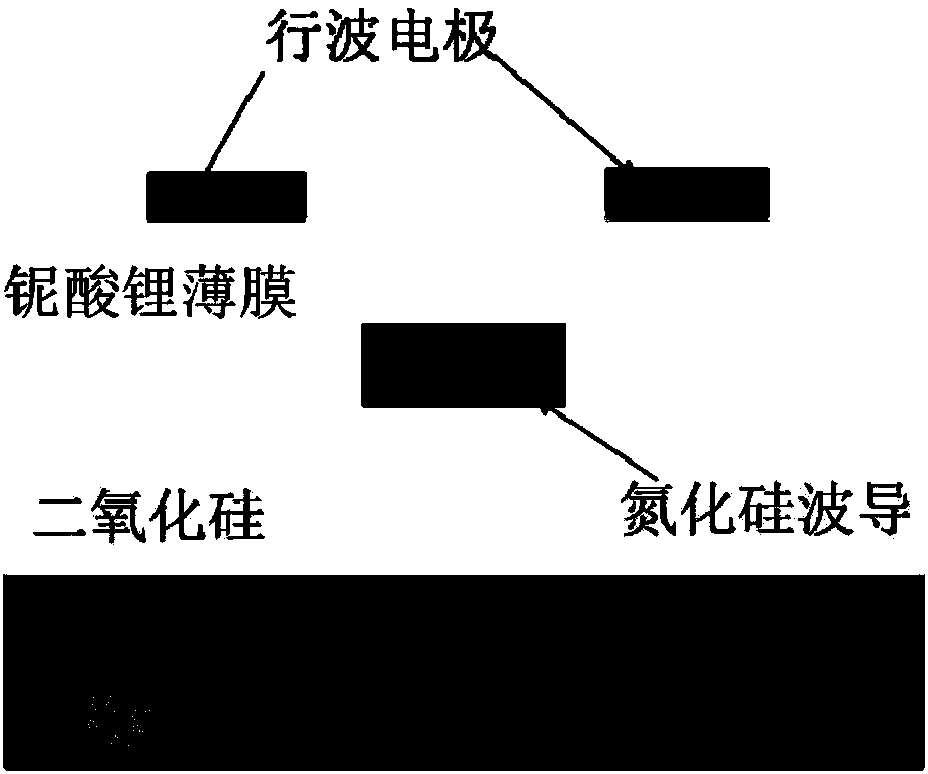

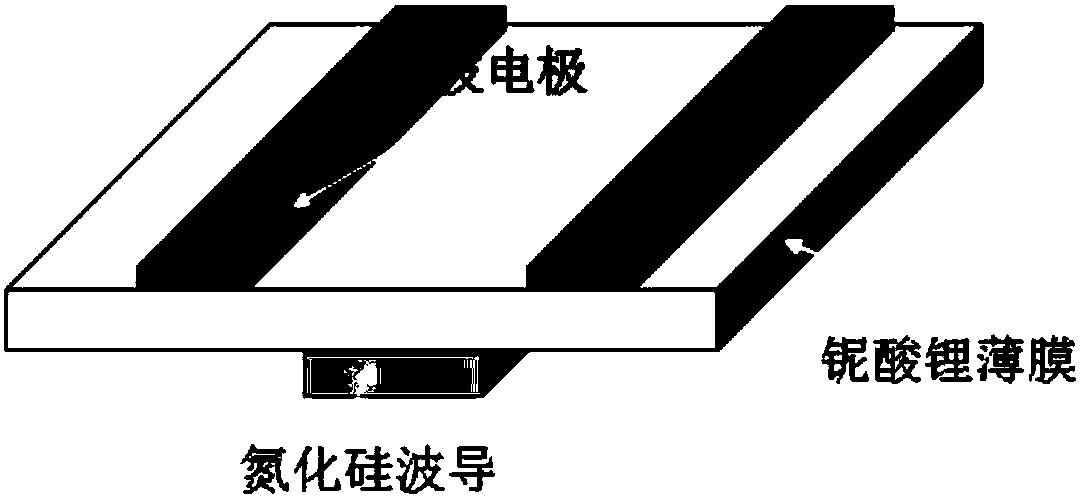

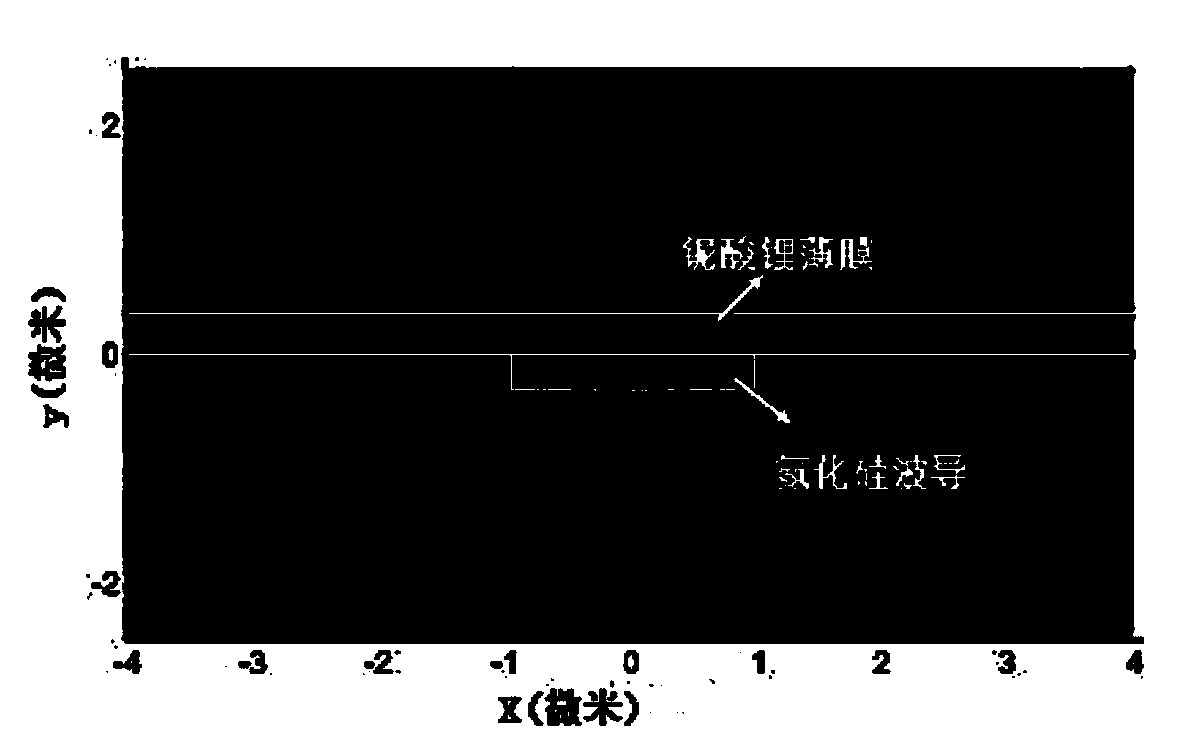

[0023] like figure 1 The cross-sectional view of the silicon nitride waveguide structure of the heterogeneously integrated lithium niobate film is shown. Silicon dioxide is deposited on the surface of the silicon material, and then silicon nitride is deposited and etched to obtain a 350-nanometer thick nitrogen in the silicon dioxide cladding layer. Silicon nitride waveguide, the silicon nitride waveguide is surrounded by silicon dioxide, and then a layer of 400nm thick lithium niobate film is attached. Prepare two traveling wave electrodes on both sides; figure 2 The perspective schematic diagram of the ridge waveguide in the silicon nitride waveguide with heterogeneous integrated lithium niobate thin film shown. like image 3 It describes the mode field diagram simulated by the finite-difference time-domain algorithm of a high-speed optical modulation chip based on heterogeneous integration of silicon nitride and lithium niobate. The upper layer is the modulable content o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com