Multi-dimensional porous electrode applied to flow battery, and preparation method and application of multi-dimensional porous electrode

A liquid flow battery and porous electrode technology, applied in battery electrodes, fuel cells, regenerative fuel cells, etc., can solve the problems of increased electrolyte flow resistance and pump work, reduced electrode permeability, and battery performance deterioration, and is easy to operate , Increase the specific surface area of the electrode and improve the catalytic activity of the electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

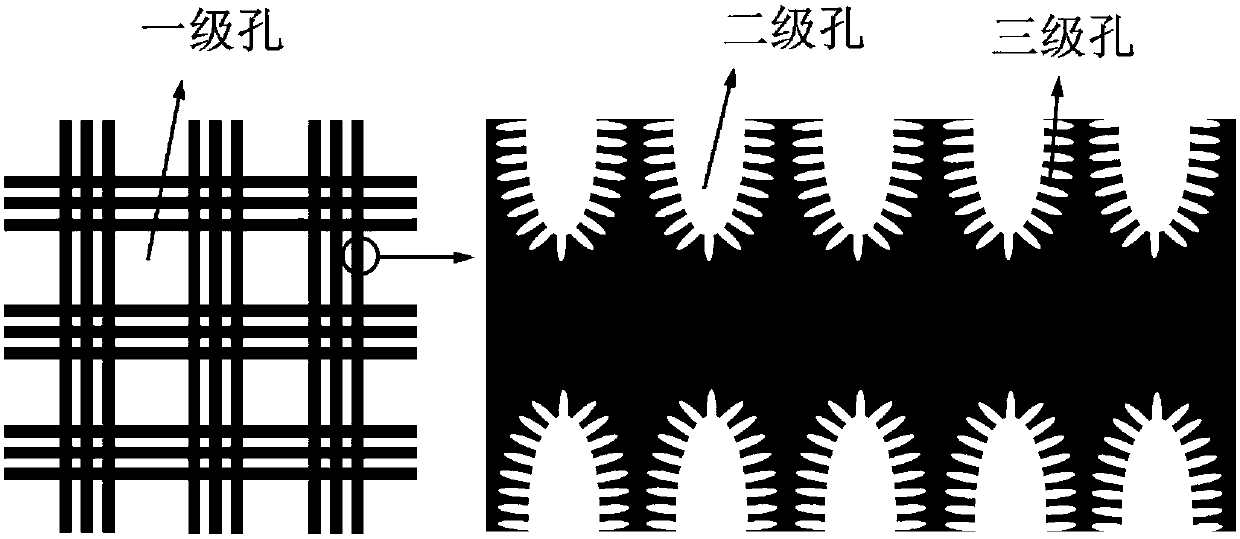

[0038] An embodiment of the present invention is a multi-scale porous electrode applied to a flow battery (the schematic diagram of the structure is shown in figure 1 shown), including a porous electrode skeleton formed by carbon fibers, secondary pores are distributed on the surface of the carbon fibers, and tertiary pores are distributed on the inner surface of the secondary pores. Carbon fiber diameter is 8μm, length is 9mm; secondary hole diameter is 300-500nm, hole depth is 50-100nm, hole spacing is 50-100nm; tertiary hole diameter is 5-10nm, hole depth is 10-30nm, hole spacing 5-10mm (scanning electron microscope photo, scanning electron microscope picture as figure 2 shown).

[0039] The above method for preparing a multi-scale porous electrode applied to a flow battery includes the following steps:

[0040]Using carbon cloth as the initial material, the initial material was placed in an acetone solution containing nickel nitrate (15% by mass), impregnated and ultras...

Embodiment 2

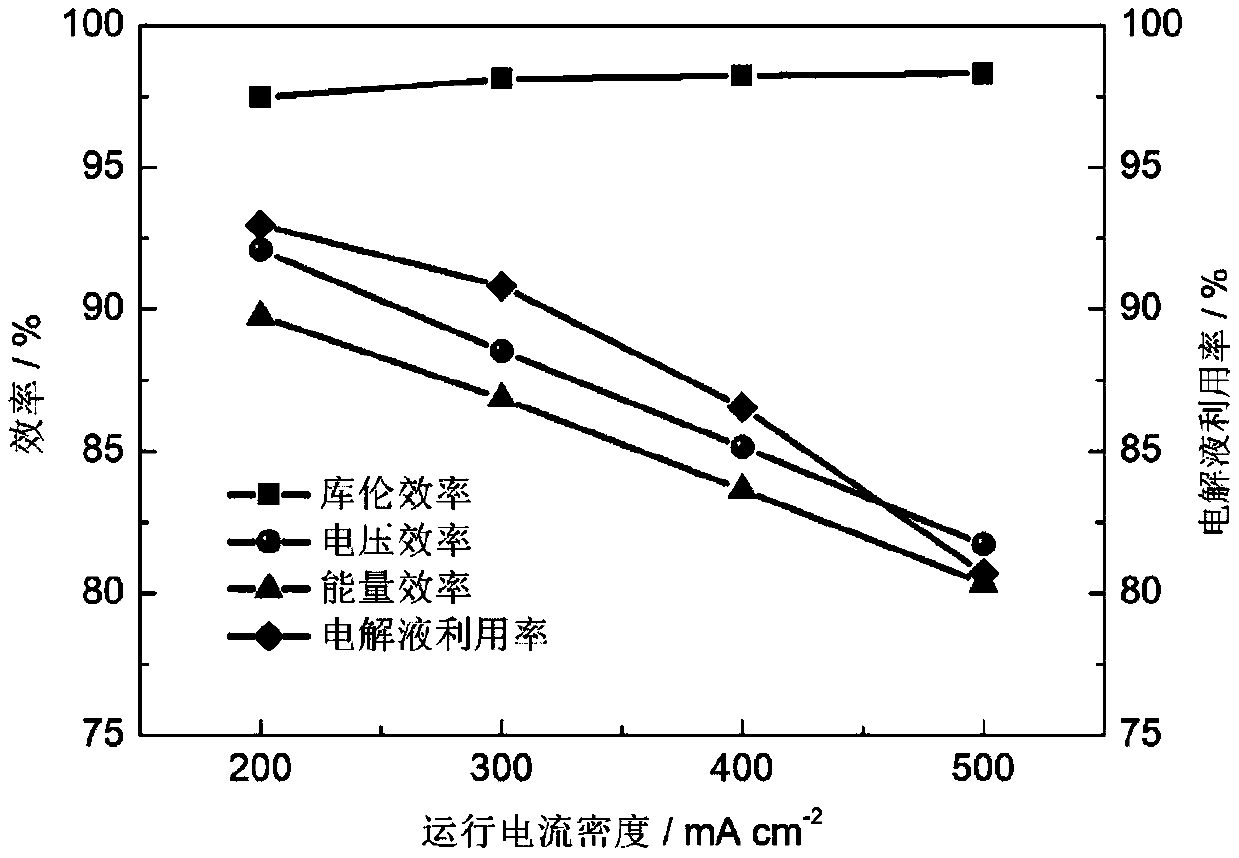

[0042] An embodiment of the present invention is an assembly of an all-vanadium redox flow battery.

Embodiment 3

[0048] An embodiment of the present invention is a multi-scale porous electrode applied to a flow battery, comprising a porous electrode skeleton formed of carbon fibers, secondary pores distributed on the surface of the carbon fibers, and tertiary pores distributed on the inner surface of the secondary pores. Carbon fiber diameter is 9μm, length is 5mm; secondary hole diameter is 400-600nm, hole depth is 80-110nm, hole spacing is 70-110nm; tertiary hole diameter is 5-10nm, hole depth is 10-30nm, hole spacing 5-10mm.

[0049] The preparation method comprises the steps of:

[0050] Using carbon felt as the initial material, the initial material was placed in an aqueous solution containing ferric chloride (25% by mass), impregnated and ultrasonicated for 20 min, and then taken out and dried at 80°C. The obtained material was put into a tube furnace for heat treatment, the atmosphere was a mixture of carbon dioxide and nitrogen, the volume fraction of carbon dioxide was 20%, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com