Preparation method of Fe-BiOBr/MOF-SO3@TiO2 photocatalyst

A MOF-SO3, photocatalyst technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problem of low utilization of light energy, easy decomposition of harmful substances Material, instability and other problems, to achieve the effect of large specific surface area, conducive to degradation, high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

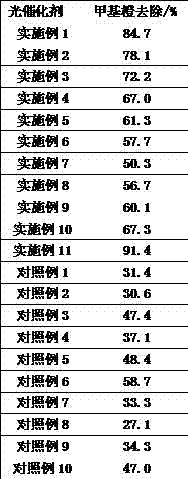

Examples

Embodiment 1

[0012] 1. A Fe-BiOBr / MOF-SO 3 @TiO 2 The preparation method of photocatalyst is characterized in that the method comprises the following steps:

[0013] Step 1 weighed 4.8gBi (NO 3 ) 3 ·5H 2 O, 0.8gFeCl 3 ·6H 2 O and 8.0 g MOF-SO 3 @TiO 2 Dissolve the nanomaterial in 35ml of ethylene glycol, then weigh 0.5gNaBr and slowly add it to the above solution, stir until it is completely dissolved, add 0.4gPVP to it, stir evenly and then ultrasonically oscillate for 30min;

[0014] Step 2. Transfer the above shaken solution to a 50ml polytetrafluoroethylene autoclave, react at 160°C for 6h, wash with deionized water three times to remove excess ions and other impurities in the precipitate, and wash with absolute ethanol Three times to remove residual organic matter, after washing, place it in an air-dried oven at 80°C for 6 hours to obtain nano-photocatalyst Fe-BiOBr / MOF-SO 3 @TiO 2 .

[0015] The MOF-SO 3 @TiO 2 Nanomaterial preparation method is as follows:

[0016] Ste...

Embodiment 2

[0019] Step 1 weighed 2.4gBi (NO 3 ) 3 ·5H 2 O, 0.8gFeCl 3 ·6H 2 O and 8.0 g MOF-SO 3 @TiO 2 Dissolve the nanomaterial in 35ml of ethylene glycol, then weigh 0.5gNaBr and slowly add it to the above solution, stir until it is completely dissolved, add 0.4gPVP to it, stir evenly and then ultrasonically oscillate for 30min;

[0020] All the other steps are the same as in Example 1.

Embodiment 3

[0022] Step 1 Weigh 1.2gBi (NO 3 ) 3 ·5H 2 O, 0.8gFeCl 3 ·6H 2 O and 8.0 g MOF-SO 3 @TiO 2 Dissolve the nanomaterial in 35ml of ethylene glycol, then weigh 0.5gNaBr and slowly add it to the above solution, stir until it is completely dissolved, add 0.4gPVP to it, stir evenly and then ultrasonically oscillate for 30min;

[0023] All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com