Cut-off carbon nanotube and TiO2 nanotube array heterostructure and preparation method and device thereof

A technology of nanotube arrays and carbon nanotubes, applied in capacitors, photosensitive devices, electrical components, etc., can solve problems such as limited development, complex organic synthesis, and high price, and achieve cheap, easy to obtain, and simple production methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

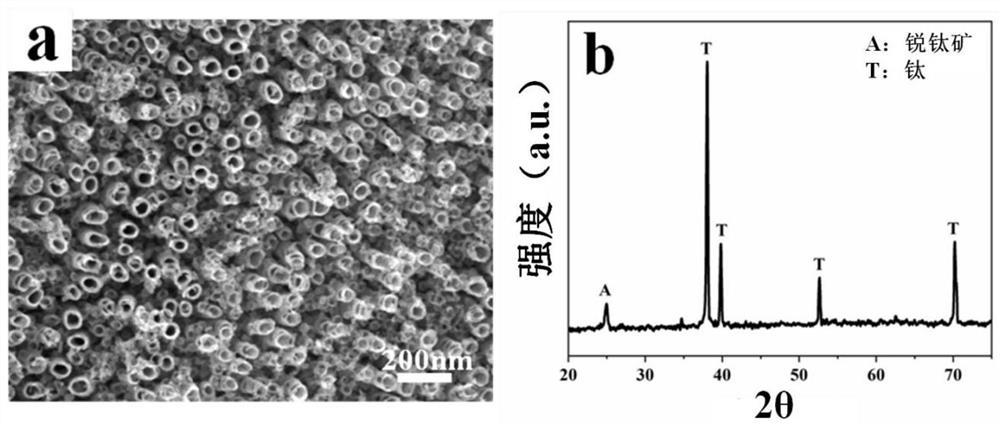

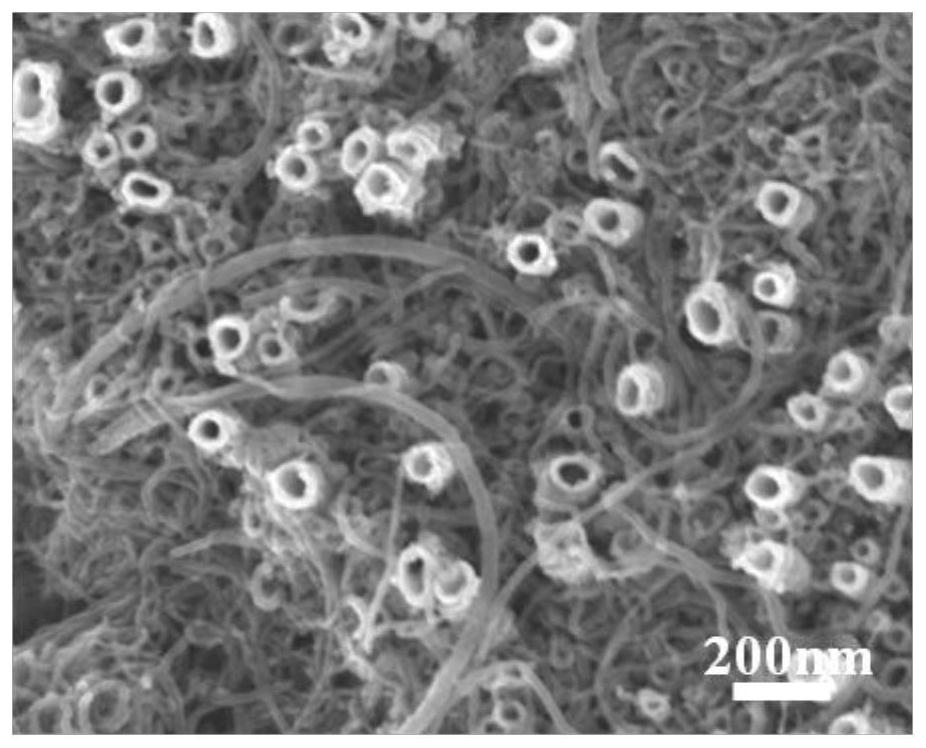

[0032] The titanium metal substrate (pure titanium foil) was polished with sandpaper, cleaned and polished, and stored in deionized water for later use. Platinum foil was used as the counter electrode. The electrolyte solution is 95% diethylene glycol by volume, 2% hydrofluoric acid solution, 3% deionized water. Anodizing at room temperature at 55 V for 1 h to form TiO on metallic titanium substrates 2 nanotube arrays such as Figure 5 As shown, TiO is formed by anodizing on the metal titanium substrate 7 2 Nanotube array 5, while in TiO 2 TiO forms at the bottom of the nanotube array 2 barrier layer 6. with TiO 2 The metallic titanium substrates of nanotube arrays were sequentially rinsed in isopropanol and deionized water to remove electrolytes, and dried in a fume hood, and then the dried samples were annealed at 530 °C for 3 h in an air atmosphere to obtain the crystal structure. figure 1 for pure TiO 2 Field Emission Scanning Electron Microscopy (FESEM) pattern (F...

Embodiment 2

[0036] The titanium metal substrate (pure titanium foil) was polished with sandpaper, cleaned and polished, and stored in deionized water for later use. Platinum foil was used as the counter electrode. The electrolyte solution is 95% diethylene glycol by volume, 2% hydrofluoric acid solution, 3% deionized water. Anodizing at room temperature 55 V for 2 h to form TiO on metallic titanium substrates 2 Nanotube arrays. with TiO 2 The metallic titanium substrates of nanotube arrays were sequentially rinsed in isopropanol and deionized water to remove electrolytes, and dried in a fume hood, and then the dried samples were annealed at 530 °C for 3 h in an air atmosphere to obtain the crystal structure.

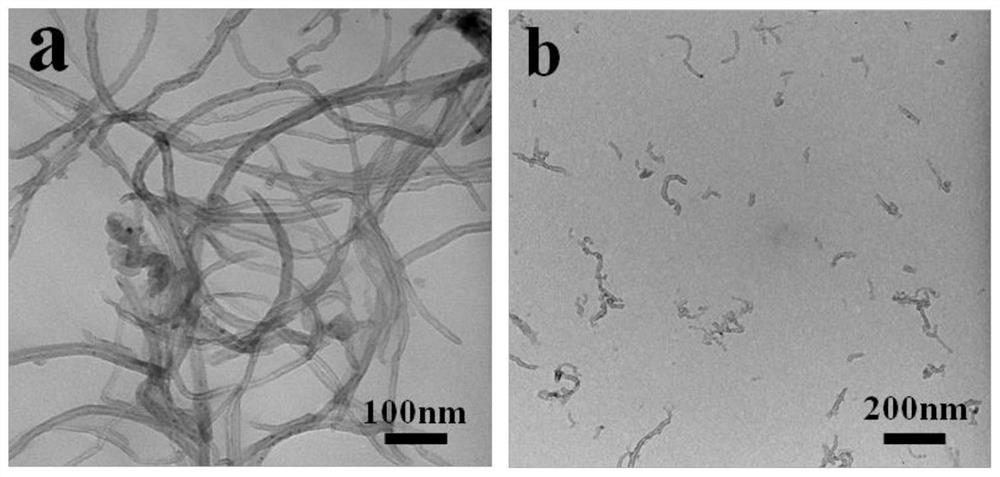

[0037] Suspend 100 mg of carbon nanotubes in 30 mL of concentrated H 2 SO 4 , stirred at room temperature for 30 min, and then added 18 mL of concentrated HNO 3 , heated and stirred at 70 ~ 80 ℃ for 10h. The cut carbon nanotubes are collected by centrifugation, repeatedly was...

Embodiment 3

[0040] The titanium metal substrate (pure titanium foil) was polished with sandpaper, cleaned and polished, and stored in deionized water for later use. Platinum foil was used as the counter electrode. The electrolyte solution is 95% diethylene glycol by volume, 2% hydrofluoric acid solution, 3% deionized water. Anodizing at room temperature at 55 V for 4 h to form TiO on metallic titanium substrates 2 Nanotube arrays. with TiO 2 The metal titanium substrate of the nanotube array was sequentially rinsed in isopropanol and deionized water to remove the electrolyte, and dried in a fume hood, and then the dried array was annealed at 530 °C for 3 h in an air atmosphere to obtain the crystal structure.

[0041] Suspend 100 mg of carbon nanotubes in 30 mL of concentrated H 2 SO 4 , stirred at room temperature for 30 min, and then added 18 mL of concentrated HNO 3 , heated and stirred at 70-80°C for 12h. The cut carbon nanotubes are collected by centrifugation, repeatedly wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com