Method for preparing nitrogen-doped graphene quantum dot material

A graphene quantum dot, nitrogen doping technology, applied in the field of nanomaterials, can solve the problems of unstable luminescence, difficult doping of graphene quantum dots, etc., to improve the charge transport capability, realize mass production, and strong fluorescence emission performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

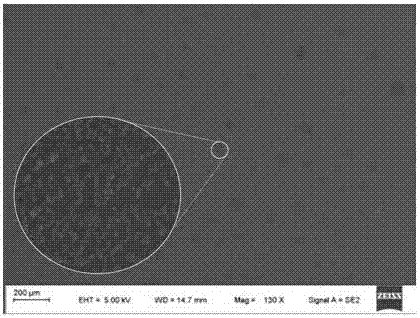

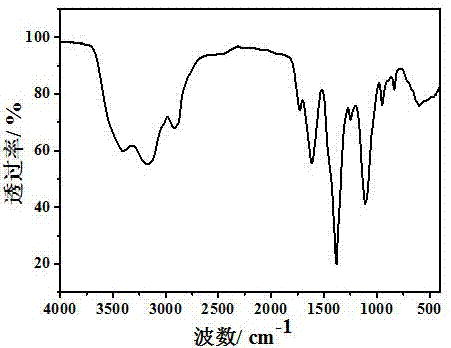

[0033] Take 0.1g of network-like reduced graphene oxide, disperse it in 100ml of 65% by mass concentrated nitric acid, stir it magnetically, heat the oil bath to 150℃ while condensing the circulating water, react at a constant temperature for 12h; then remove the condensed water and continue to evaporate at a constant temperature for 2h; Cool to room temperature, then add ultra-pure water and ultrasonically disperse for 15 minutes; filter, rotary evaporate and concentrate the filtrate to 10 mL, and put it into a 3000Da dialysis bag for dialysis for 2 days; the resulting dialysate is concentrated by rotary evaporation again to obtain high-concentration nitrogen-doped graphene quantum Dots; finally, vacuum freeze-drying at -50~-60℃ for 10h to obtain brown nitrogen-doped graphene quantum dots with a yield of 70%.

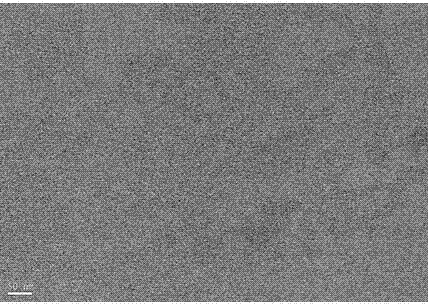

[0034] The particle size of brown nitrogen-doped graphene quantum dots is about 8nm; the fluorescence emission color of quantum dots under the irradiation of a 365nm ultra...

Embodiment 2

[0036] Take 0.1g of network-shaped reduced graphene oxide and disperse it in 100ml of 65% by mass concentrated nitric acid. Under magnetic stirring, the oil bath is heated to 150°C while circulating water is condensed and reacted at a constant temperature for 24h; then the condensed water is removed and the constant temperature evaporation is continued for 2h; Cool to room temperature, add ultrapure water and ultrasonically disperse for 15min; filter, and concentrate the filtrate by rotary evaporation to 15mL; then put it into a 3000Da dialysis bag for dialysis for 1 day; the dialysate is concentrated by rotary evaporation again to obtain high-concentration nitrogen-doped graphene Quantum dots; finally, vacuum freeze-drying at -50~-60℃ for 10h to obtain yellow nitrogen-doped graphene quantum dots. The yield was 54%.

[0037] The particle size of the yellow nitrogen-doped graphene quantum dots is about 5nm; the fluorescent emission color of the quantum dots under the irradiation o...

Embodiment 3

[0039] Take 0.1g of network-shaped reduced graphene oxide and disperse it in 100ml of 65% by mass concentrated nitric acid. Under magnetic stirring, the oil bath is heated to 150°C while circulating water is condensed, reacting at a constant temperature for 48h; then the condensed water is removed and evaporation is continued at constant temperature for 1.5h ; Cool to room temperature, add ultra-pure water and ultrasonically disperse for 10 min; filter, rotary evaporate and concentrate the filtrate to 15 mL, and put it into a 3000Da dialysis bag for 2 days; the dialysate is concentrated by rotary evaporation again to obtain high-concentration nitrogen-doped graphene quantum dots ; Finally, vacuum freeze-drying at -50~-60℃ for 10h to obtain light yellow nitrogen-doped graphene quantum dots. The yield was 35%.

[0040] The particle size of the light yellow nitrogen-doped graphene quantum dots is about 4nm; the fluorescent emission color of the quantum dots under the irradiation of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com