A kind of preparation method for treating oily sewage flocculant

A flocculant and sewage technology, applied in the direction of chemicals for biological control, water/sewage treatment, chemical instruments and methods, etc., can solve the difficult to meet the requirements of water treatment, a large amount of sludge and scum, dosing Large volume and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

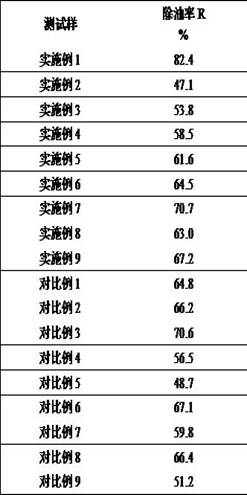

Examples

Embodiment 1

[0010] Weigh 16 parts by weight of chitosan into a three-necked flask, add 67 parts by weight of isopropanol, 19.5 parts by weight of NaOH solid and 100 parts by weight of deionized water, and stir and swell for 2 to 5 hours at a temperature of 60°C. Dissolve 10 parts by weight of chloroacetic acid in 30 parts by weight of isopropanol, and add it dropwise to the above solution while stirring, and complete the dropwise addition within 20 minutes. During the dropping process, the temperature is controlled at 60-70°C. Continue to react for 8h. After cooling, filter with a Buchner funnel, use 70% ethanol solution to remove salt and alkali from the filter residue, and filter 3 to 5 times. Then wash and filter with 95% ethanol by mass fraction, operate 3 times, and vacuum-dry the above-mentioned powder solid at 70°C to obtain sodium carboxymethyl chitosan.

[0011] 2) Take 5 parts by weight of the above-mentioned sodium carboxymethyl chitosan and put it in a beaker filled with acet...

Embodiment 2

[0015] It is exactly the same as Example 1, except that 10 parts by weight of chitosan is weighed in a beaker, and 60 parts by weight of isopropanol and 15.5 parts by weight of NaOH solid are added into the beaker.

Embodiment 3

[0017] It is exactly the same as Example 1, except that 11 parts by weight of chitosan is weighed in a beaker, and 62 parts by weight of isopropanol and 16.5 parts by weight of NaOH solid are added into the beaker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com