Strength sensitivity evaluation method for shale reservoir

An evaluation method and technology for shale reservoirs, applied in the field of sensitivity evaluation of shale reservoirs, can solve problems such as waste of heat energy, large water resources, and unused heat energy of thermal residues, and achieve the effect of overcoming limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

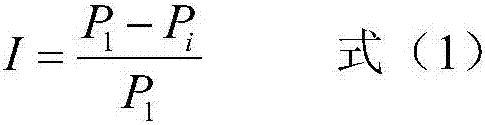

Method used

Image

Examples

Embodiment 1

[0039] Two inter-salt shale oil reservoir cores (named C-1 and C-2) with similar properties at adjacent positions were taken, both of which have a diameter of 2.5 cm and a height of 5 cm. Follow the steps below to evaluate water sensitivity:

[0040] 1) Put the core C-1 into the core holder, and fill the intermediate container with simulated formation water (for inter-salt shale oil reservoirs without water, the simulated formation water is the saturated brine);

[0041] 2) Turn on the pump, discharge the gas in the pipeline at the liquid inlet end of the core holder, so that the pipeline is completely filled with liquid, then adjust the flow rate of the advection pump to less than the critical flow rate (0.3ml / min), open the valve, and make the simulated formation Water flows through the core C-1 for displacement operation, the injection volume is 10 times the pore volume, and the injection flow rate is 0.2ml / min;

[0042] 3) Stop the pump, soak the core C-1 in the simulate...

Embodiment 2

[0046] Two shale gas reservoir cores with similar properties in adjacent positions (named C-3 and C-4) were taken, both of which have a diameter of 2.5 cm and a height of 4 cm. Follow the steps below to evaluate acid sensitivity:

[0047] 1) Put the core C-3 into the core holder, and fill the intermediate container with simulated formation water;

[0048] 2) Turn on the pump, discharge the gas in the pipeline at the liquid inlet end of the core holder, so that the pipeline is completely filled with liquid, then adjust the flow rate of the advection pump to be less than the critical flow rate, open the valve, and let the simulated formation water flow through the core C-3 For displacement operations, the injection volume is 1 times the pore volume, and the injection flow rate is 0.1ml / min;

[0049] 3) Stop the pump, soak the core C-3 in the simulated formation water for 2 hours, take it out, blot the moisture on its surface with filter paper, and measure the uniaxial compressi...

Embodiment 3

[0053] Two shale gas reservoir cores (named C-5 and C-6) with similar properties at adjacent positions were taken, both of which have a diameter of 2.5 cm and a height of 6 cm. Follow the steps below to evaluate alkali sensitivity:

[0054] 1) Put the core C-5 into the core holder, and fill the intermediate container with simulated formation water (the measured pH value is 7);

[0055] 2) Turn on the pump, discharge the gas in the pipeline at the liquid inlet end of the core holder, so that the pipeline is completely filled with liquid, then adjust the flow rate of the advection pump to less than the critical flow rate, open the valve, and let the simulated formation water flow through the core C-5 Carry out displacement operations, the injection volume is 15 times the pore volume, and the injection flow rate is 0.1ml / min;

[0056] 3) Stop the pump, soak the core C-5 in simulated formation water for 12 hours, take it out, blot the moisture on its surface with filter paper, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com