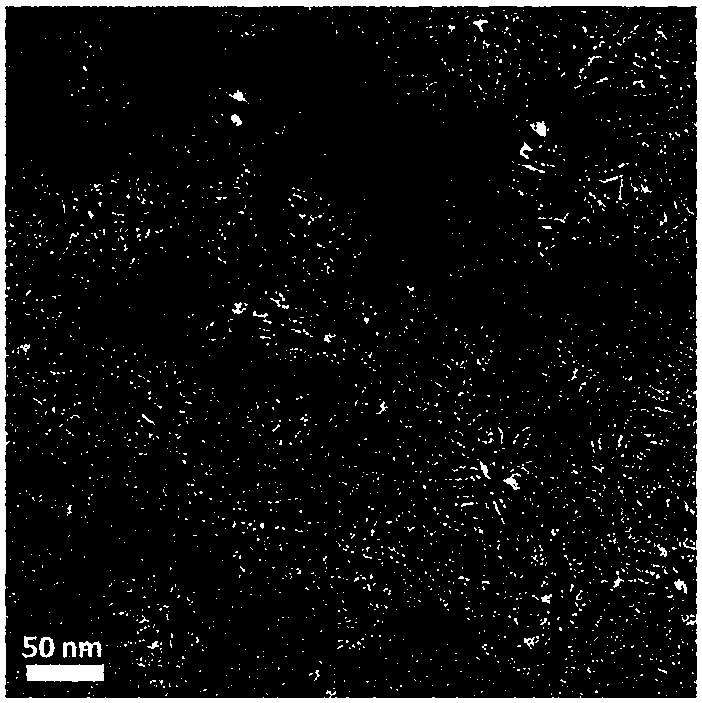

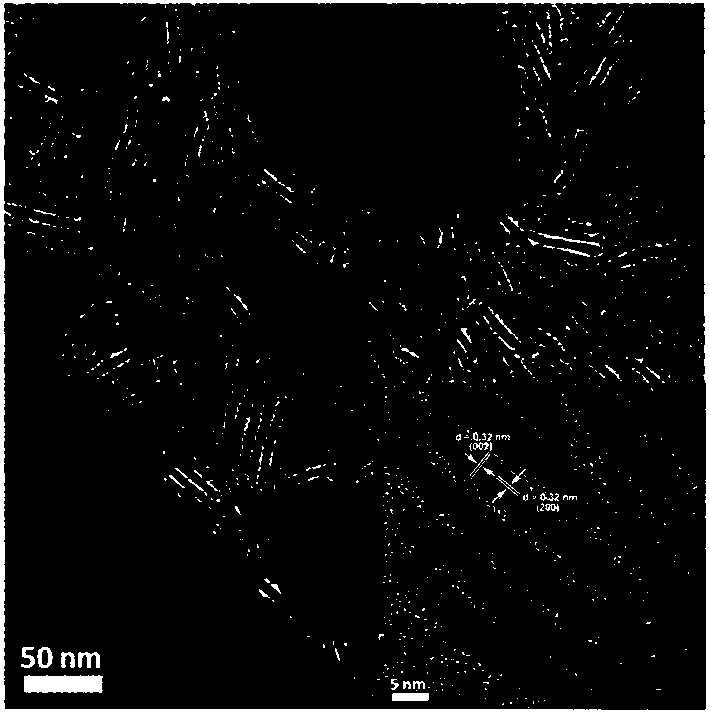

Lead telluride nano rod with uniform size, and preparation method and applications thereof

A nanorod and lead telluride technology is applied in the field of nanomaterials to achieve the effects of good solubility, uniform size distribution and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this example, lead telluride nanorods were synthesized at a temperature of 100 °C, and the specific steps are as follows:

[0030] 1) Preparation of lead precursor: under nitrogen protection, 89 mg (0.4 mmol) of lead oxide, 170 mg (1 mmol) of trans-2-decenoic acid and 8 g of octadecene were added to a 50 mL three-necked flask , stirring for 1 hour at a temperature of 120 °C until the solution becomes clear and transparent, then vacuumizing for 1 hour at a temperature of 110 °C to remove water and oxygen in the three-necked flask to obtain a lead precursor, stand-by;

[0031] 2) Preparation of tellurium precursor: In a nitrogen glove box, add 153 mg (1.2 mmol) tellurium element into a glass bottle containing 1.2 ml tris(diethylamino)phosphine, and stir at room temperature until the tellurium element Completely dissolved in the solution to obtain a tellurium precursor, ready for use;

[0032] 3) Synthesis reaction under preset lead-tellurium precursor ratio and tempe...

Embodiment 2

[0037] In this example, lead telluride nanorods were synthesized at a temperature of 120 °C, and the specific steps are as follows:

[0038] 1) Preparation of lead precursor: under nitrogen protection, 89 mg (0.4 mmol) of lead oxide, 170 mg (1 mmol) of trans-2-decenoic acid and 8 g of octadecene were added to a 50 mL three-necked flask , stirred at 120° C. for 1 hour until the solution became clear and transparent, then vacuumized at 110° C. for 1 hour to remove water and oxygen in the three-necked flask to obtain a lead precursor for use;

[0039] 2) Preparation of tellurium precursor: In a nitrogen glove box, add 153 mg (1.2 mmol) of tellurium into a glass bottle containing 1.2 ml of tris(diethylamino)phosphine, stir and dissolve at room temperature until tellurium The elemental substance is completely dissolved in the solution to obtain a tellurium precursor, which is ready for use;

[0040] 3) Reaction at preset lead-tellurium precursor ratio and temperature: 60 μL tellur...

Embodiment 3

[0045] In this example, lead telluride nanorods were synthesized at a temperature of 140 °C, and the specific steps are as follows:

[0046] 1) Preparation of lead precursor: under nitrogen protection, 89 mg (0.4 mmol) of lead oxide, 170 mg (1 mmol) of trans-2-decenoic acid and 8 g of octadecene were added to a 50 mL three-necked flask , stirred at 120° C. for 1 hour until the solution became clear and transparent, then vacuumized at 110° C. for 1 hour to remove water and oxygen in the three-necked flask to obtain a lead precursor for use;

[0047] 2) Preparation of tellurium precursor: In a nitrogen glove box, add 153 mg (1.2 mmol) of tellurium into a glass bottle containing 1.2 ml of tris(diethylamino)phosphine, stir and dissolve at room temperature until tellurium The elemental substance is completely dissolved in the solution to obtain a tellurium precursor, which is ready for use;

[0048] 3) Reaction at preset lead-tellurium precursor ratio and temperature: 60 μL tellur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com