Method for recovering bezafibrate from bezafibrate synthesis waste liquid

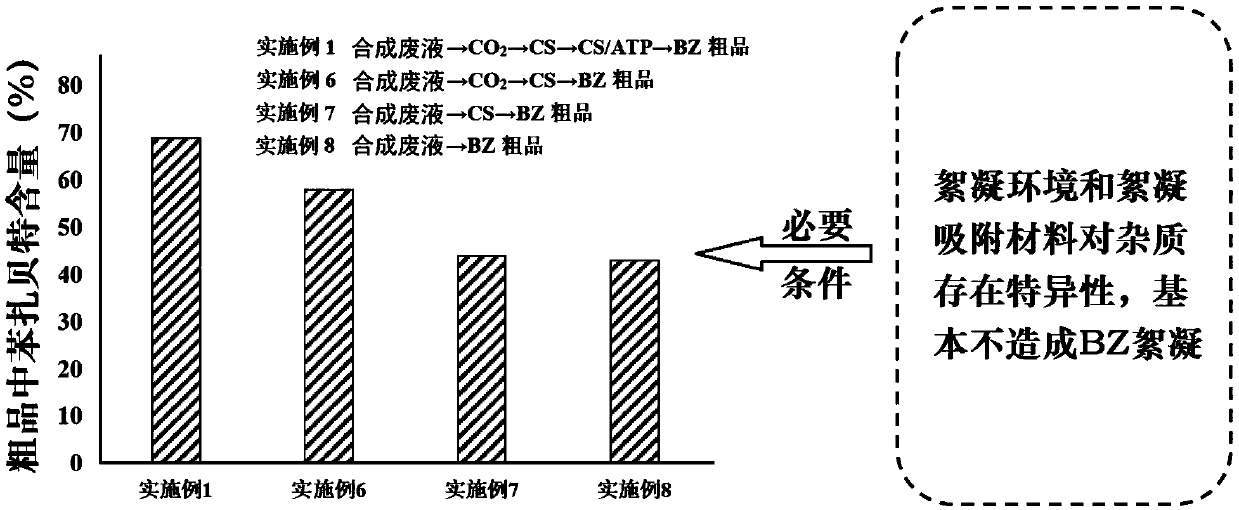

A technology of bezafibrate and waste liquid is applied in the field of drug synthesis, which can solve the problems of stickiness and blackening, increase production cost, difficulty in recycling and the like, and achieve the effects of high purity of crude product and simple and easy operation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 100mL of synthetic waste liquid, add 1L of water to dissolve and dilute, and pass CO into it at a rate of 200mL / min 2 After 30 minutes, add 15 mL of chitosan solution with a mass concentration of 1%, flocculate at room temperature for 30 minutes, and suction filter; then add 22 g of chitosan / attapulgite complex to the obtained filtrate, stir at room temperature for 15 minutes, and let stand for 30 minutes , after suction filtration, the filtrate was acidified with 15% hydrochloric acid to pH=3.5, stirred at room temperature for 1 h until the precipitation was complete, filtered, and the filter cake was dried to obtain 25 g of crude bezafibrate.

[0024] The preparation method of the 1% chitosan solution is as follows: 1 g of chitosan is dissolved in 100 mL of 1% acetic acid aqueous solution with a mass fraction.

[0025] The chitosan / attapulgite composite was prepared by the following method: 1 g of chitosan was dissolved in 100 mL of 1% acetic acid aqueous solutio...

Embodiment 2

[0027] Take 500mL of synthetic waste liquid, add 2.5L of water to dissolve and dilute, and pass CO into it at a rate of 200mL / min 2 After 20 minutes to pH 5, add 60 mL of chitosan solution with a mass concentration of 1%, suction filter after flocculation at room temperature for 20 minutes; After filtration, the filtrate was acidified with 15% hydrochloric acid to pH = 3, stirred at room temperature for 1 h until the precipitation was complete, filtered, and the filter cake was dried to obtain 102 g of crude bezafibrate.

[0028] The preparation method of the 1% chitosan solution is as follows: 1 g of chitosan is dissolved in 100 mL of 1% acetic acid aqueous solution with a mass fraction.

[0029] The chitosan / attapulgite composite was prepared by the following method: 1 g of chitosan was dissolved in 100 mL of 1% acetic acid aqueous solution to obtain a chitosan sol, 6 g of attapulgite was added to the sol and stirred continuously at room temperature for 48 h After standing ...

Embodiment 3

[0031] Take 1L of synthetic waste liquid, add 15L of water to dissolve and dilute, and pass CO into it at a rate of 200mL / min 2 To pH 6, after 40 minutes, add 160 mL of chitosan solution with a mass concentration of 1%, suction filter after 30 minutes of flocculation at room temperature; After suction filtration, the filtrate was acidified with 15% hydrochloric acid to pH=4, stirred at room temperature for 1 h until the precipitation was complete, filtered, and the filter cake was dried to obtain 225 g of crude bezafibrate.

[0032] The preparation method of the 1% chitosan solution is as follows: 1 g of chitosan is dissolved in 100 mL of 1% acetic acid aqueous solution with a mass fraction.

[0033] The chitosan / attapulgite composite was prepared by the following method: 1 g of chitosan was dissolved in 100 mL of 1% acetic acid aqueous solution to obtain a chitosan sol, 6 g of attapulgite was added to the sol and stirred continuously at room temperature for 48 h After standi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com