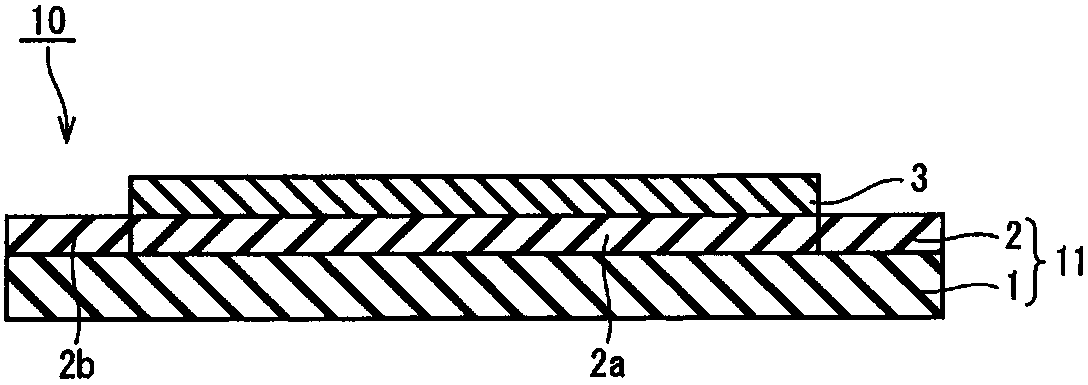

Dicing tape integrated adhesive sheet

A dicing sheet, integrated technology, applied in the direction of adhesive, adhesive type, electric solid device, etc., can solve the problem of inability to pick up properly, and achieve the effect of good flexibility, cost reduction, and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

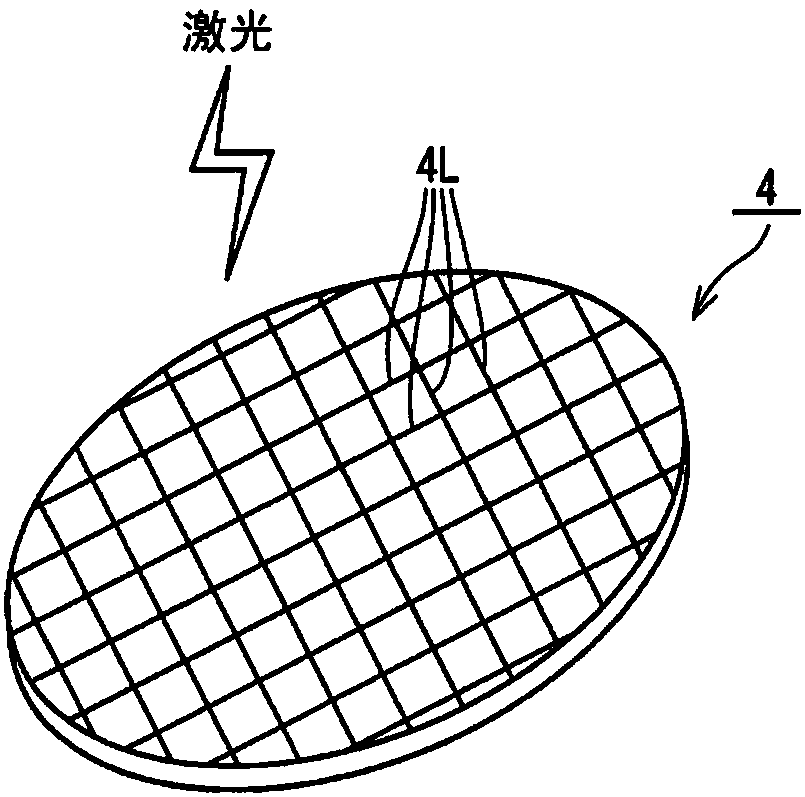

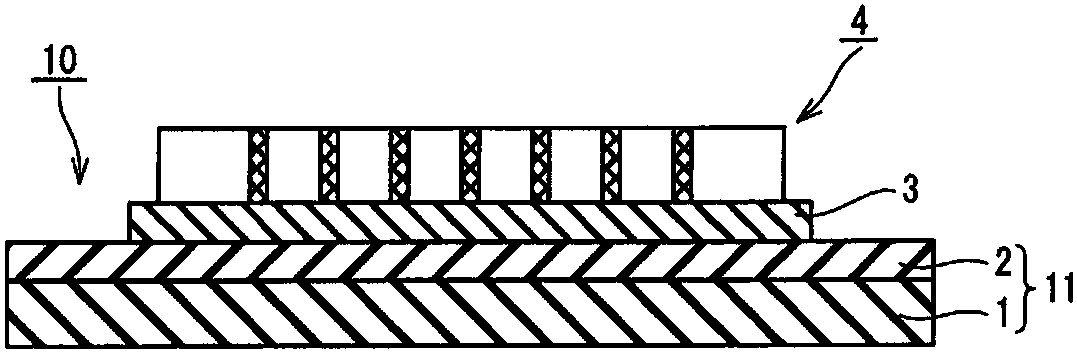

Method used

Image

Examples

Embodiment 1

[0194]

[0195] Heat-expandable microspheres A (Matsumoto Microsphere F-50D: manufactured by Matsumoto Yushi Pharmaceutical Co., Ltd.: average particle diameter: 13.4 μm) were prepared.

[0196] On the other hand, prepare 2-ethylhexyl acrylate-ethyl acrylate-methyl methacrylate (in terms of monomer ratio, 2-ethylhexyl acrylate: 30 parts by weight, ethyl acrylate: 70 parts by weight , methyl methacrylate: 5 parts by weight) in 100 parts by weight of copolymer-based adhesive (2 parts by weight of compounding polyurethane cross-linking agent), be compounded with the toluene solution of 30 parts by weight of the aforementioned heat-expandable microspheres A, to dry The resulting thickness was applied to a surface obtained by peeling one side of a PET film having a thickness of 50 μm so as to be 45 μm, followed by drying to obtain an adhesive layer A. The obtained pressure-sensitive adhesive layer was stuck to an 80-micrometer polyolefin film, and the dicing sheet A was obtained....

Embodiment 2

[0203]

[0204] Heat-expandable microspheres B (Matsumoto Microsphere FN-100SS: manufactured by Matsumoto Yuyu Pharmaceutical Co., Ltd.: average particle diameter: 8.5 μm) were prepared.

[0205] On the other hand, prepare 2-ethylhexyl acrylate-ethyl acrylate-methyl methacrylate (in terms of monomer ratio, 2-ethylhexyl acrylate: 30 parts by weight, ethyl acrylate: 70 parts by weight , methyl methacrylate: 5 parts by weight) 100 parts by weight of copolymer-based adhesive (2 parts by weight of compounding polyurethane cross-linking agent) is compounded with the toluene solution of 30 parts by weight of the aforementioned heat-expandable microspheres B, to dry The resulting thickness was applied to one side of a PET film having a thickness of 50 μm, which was subjected to a release treatment, and dried to obtain an adhesive layer B. The obtained pressure-sensitive adhesive layer was stuck to an 80-micrometer polyolefin film, and the dicing sheet B was obtained.

[0206]

[...

Embodiment 3

[0209]

[0210] For 100 parts of acrylic resin (trade name "SG-P3", manufactured by Nagase ChemteX Corporation, weight average molecular weight 850000), 12 parts of phenolic resin (trade name "MEH-7851-4H", manufactured by Meiwa Chemical Industry Co., Ltd.), filler (Brand name "SE-2050MC" manufactured by Admatechs Co. Ltd., average particle diameter: 0.5 μm): 170 parts were dissolved in methyl ethyl ketone to prepare an adhesive composition solution B having a solid content concentration of 18% by weight.

[0211] After applying the adhesive composition solution B to a release-treated film (release liner) formed of a polyethylene terephthalate film with a thickness of 50 μm that has been subjected to a silicone release treatment, the The drying was carried out at ℃ for 2 minutes. Thus, a die-bonding film B having a thickness (average thickness) of 10 μm was obtained.

[0212]

[0213] The PET film was peeled off from the dicing sheet A, and the die-bonding film B was attach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com