A kind of copper-sulfur separation flotation method

A copper-sulfur separation, copper-sulfur technology, applied in flotation, solid separation, etc., can solve the problems of mine wastewater not up to standard, high production cost, corrosion equipment, etc., achieve separation of copper and sulfur, reduce concentration, reduce adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

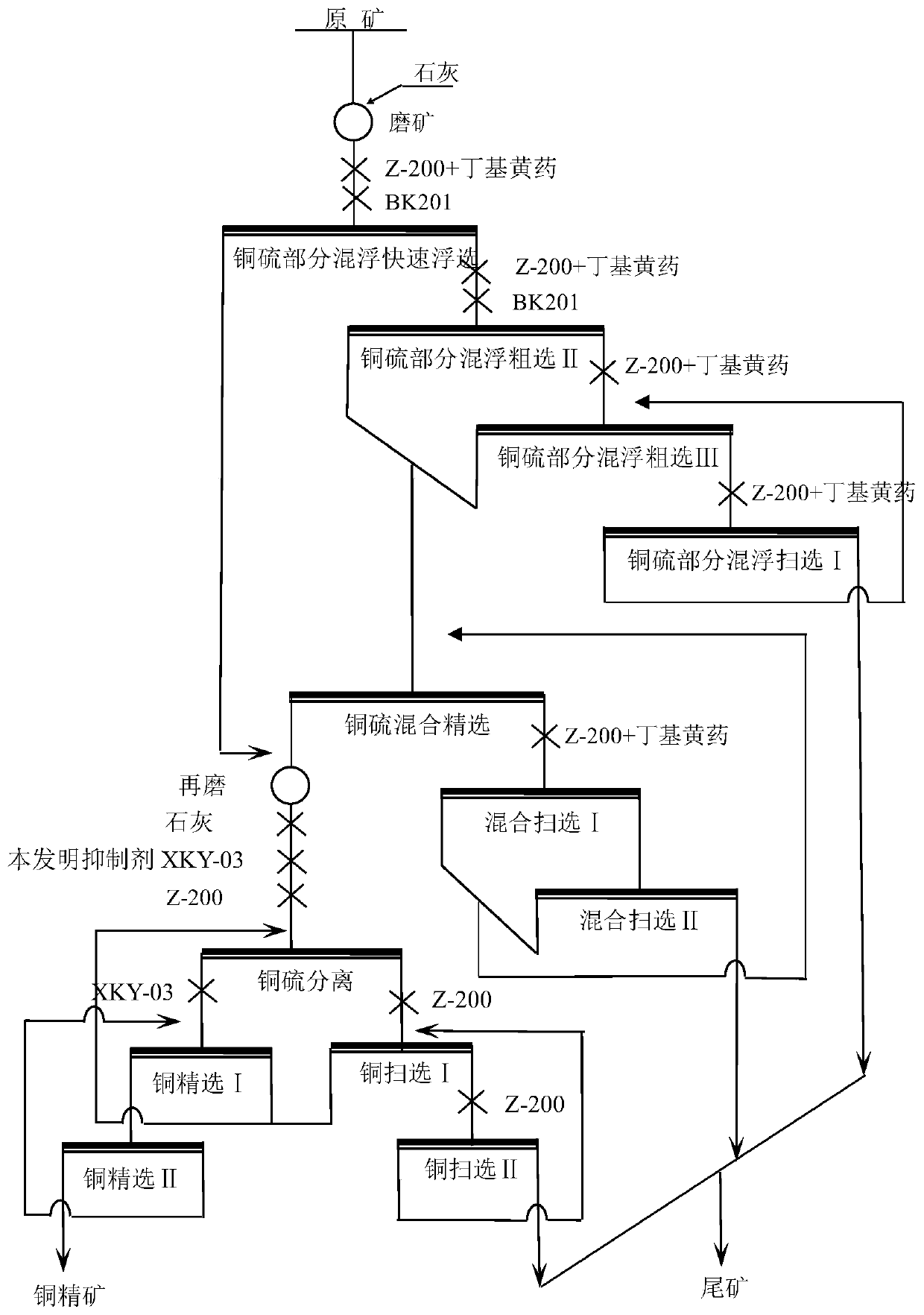

Image

Examples

Embodiment 1

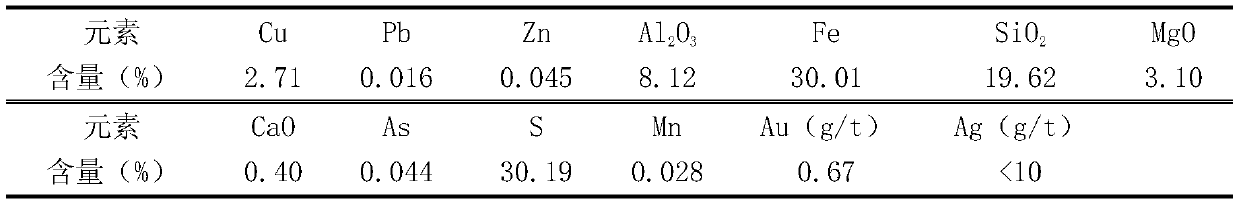

[0030] Embodiment 1, ore properties: the main metal minerals in the ore include chalcocite, chalcopyrite, blue chalcocite, copper blue, pyrite, magnetite, limonite, lead vanadium, etc., and the gangue minerals include quartz , halloysite, sericite, potash feldspar, etc. The results of multi-element analysis of raw ore are shown in Table 1, the phase analysis of copper is shown in Table 2, and the results of mineral composition measurement of ore are shown in Table 3.

[0031] Table 1 Chemical multi-element analysis results of raw ore

[0032]

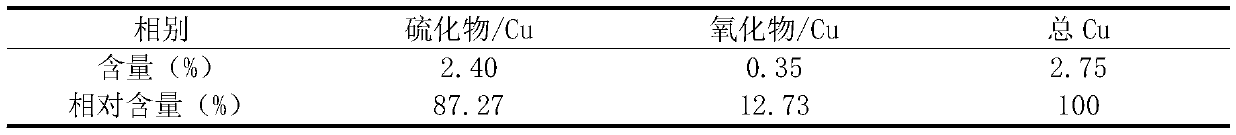

[0033] Table 2 The results of phase analysis of raw ore copper

[0034]

[0035] Table 3 Mineral content analysis results

[0036]

[0037]Lime inhibitor was added to the copper-sulfur separation roughing operation of this ore, the amount of lime was 10Kg / t relative to the raw ore, and under the conditions of pulp pH=12-13, the test results are shown in Table 4.

[0038] Table 4 lime as inhibitor test results

[0039]

...

Embodiment 2

[0053] Embodiment 2, preparation inhibitor XKY-03, raw material composition is as follows: sodium humate is 65.50%, potassium permanganate is 27.00%, C 2 h 3 NaO 2 S is 7.50%, and it is prepared under normal temperature and pressure with a beaker as a container and a magnetic stirrer for 40 to 50 minutes.

[0054] The technological process steps of copper sulfur separation are:

[0055] 1) Add ore, lime and water into the ball mill, and grind the ore until the particle size is -0.074mm and the content is 60%;

[0056] 2) Pour the ground pulp into the flotation machine, stir, and carry out the rapid flotation operation of mixed flotation of copper and sulfur to obtain mixed coarse concentrate I and rapid flotation tailings; the process conditions of rapid flotation of copper and sulfur For: add collector Z-200: 60g / t, collector butyl xanthate: 20g / t, action time 3min, add foaming agent BK201: 28g / t, action time 1min;

[0057] 3) The rapid flotation tailings obtained in step...

Embodiment 3

[0065] Embodiment 3, preparation inhibitor XKY-03, raw material composition is as follows: sodium humate is 66%, potassium permanganate is 29, C 2 h 3 NaO 2 S is 6%, and it is prepared under normal temperature and pressure with a beaker as a container and a magnetic stirrer for 40 to 50 minutes.

[0066] The technological process steps of copper sulfur separation are:

[0067] 1) Add ore, lime and water into the ball mill, and grind the ore until the particle size is -0.074mm and the content is 60%;

[0068] 2) Pour the ground pulp into the flotation machine, stir, and carry out the rapid flotation operation of mixed flotation of copper and sulfur to obtain mixed coarse concentrate I and rapid flotation tailings; the process conditions of rapid flotation of copper and sulfur For: add collector Z-200: 70g / t, collector butyl xanthate: 25g / t, action time 3min, add foaming agent BK201: 30g / t, action time 2min;

[0069] 3) The rapid flotation tailings obtained in step 2) are th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com