Fluorine waste liquid treatment method

A treatment method and technology for fluorine waste liquid, applied in the directions of fluorosilicic acid, tetrafluoroboric acid, halide silicon compounds, etc., can solve the problems such as restricting the production capacity of glass product manufacturers, unfavorable to the sustainable development of the glass industry, and restricting the sales of fluorine waste liquid, etc. To achieve the effect of promoting sustainable development, good economic benefits, and alleviating the pressure of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

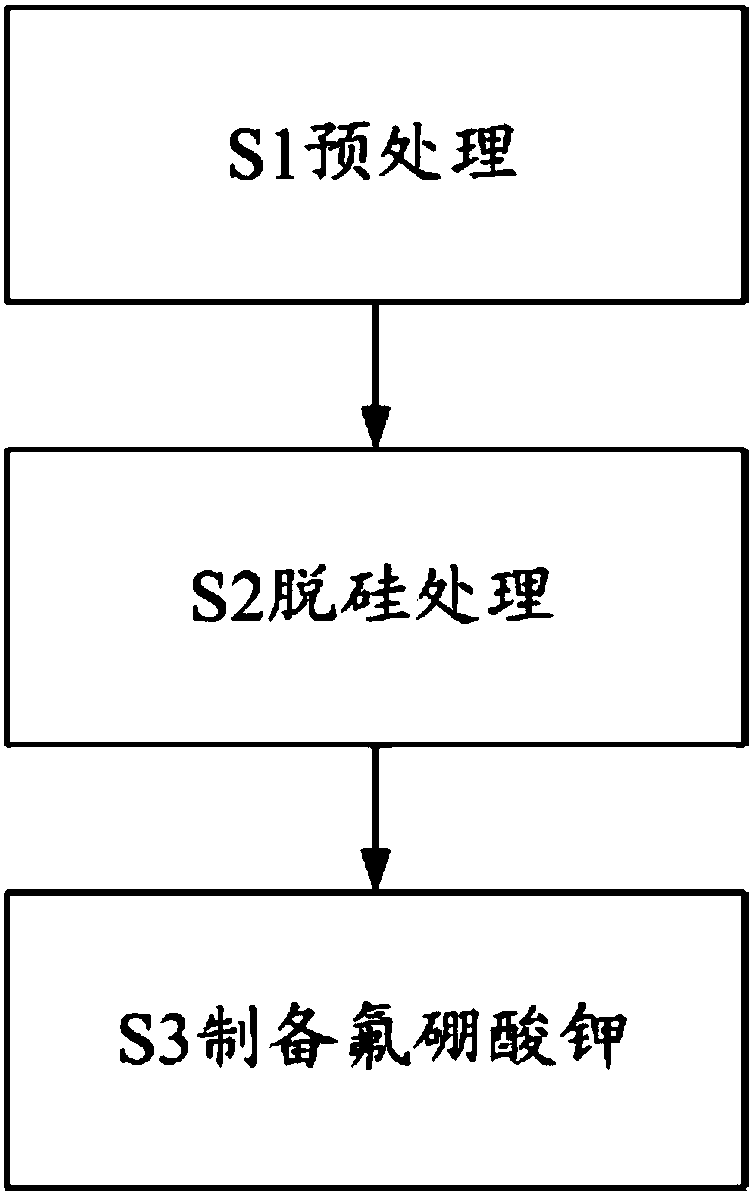

[0030] Such as figure 1 As shown, a kind of fluorine waste liquid treatment method is provided in the embodiment, implement according to the following steps:

[0031] S11 detects the content of hydrofluoric acid and fluorosilicic acid in the fluorine waste liquid;

[0032] S12 According to the content of hydrofluoric acid and fluosilicic acid, dissolving a theoretical amount of boric acid into hot water at 75-85°C to obtain a boric acid solution;

[0033] S21, adding boric acid solution and fluorine waste liquid to the desiliconization tank while hot, and reacting for 30 minutes to obtain cloudy liquid A;

[0034] S22, suction-filtering and washing the turbid solution A of S21 to obtain silica on the filter residue, aging the filtrate for 4 hours, reducing the content of silica in the mother liquor, and obtaining a supernatant and a turbid solution;

[0035] S23, returning the turbid liquid of S22 to suction filtration and circularly washing the filter residue silica to obta...

Embodiment 2

[0047] Such as figure 1 As shown, a kind of fluorine waste liquid treatment method is provided in the embodiment, implement according to the following steps:

[0048] S11 detects the content of hydrofluoric acid and fluorosilicic acid in the fluorine waste liquid;

[0049] S12 According to the content of hydrofluoric acid and fluosilicic acid, dissolving a theoretical amount of boric acid into hot water at 75-85°C to obtain a boric acid solution;

[0050] S21, adding boric acid solution and fluorine waste liquid to the desiliconization tank while hot, and reacting for 30 minutes to obtain cloudy liquid A;

[0051] S22, suction-filtering and washing the turbid solution A of S21 to obtain silica on the filter residue, aging the filtrate for 4 hours, reducing the content of silica in the mother liquor, and obtaining a supernatant and a turbid solution;

[0052] S23, returning the turbid liquid of S22 to suction filtration and circularly washing the filter residue silica;

[00...

Embodiment 3

[0063] Take 200 g of fluorine waste liquid, the hydrofluoric acid content of this fluorine waste liquid is 5.02% and the content of fluosilicic acid is 8.40% after testing. Put in a 1000ml plastic cup, take another 19.63g of boric acid into the beaker, add 100ml of water, heat to dissolve, or add 100ml of hot water at 75°C to dissolve, add the dissolved boric acid solution to the fluorine waste liquid while it is hot, and continuously Stir until cooling to obtain a mixture of fluoboric acid and silicon dioxide. Suction filter the fluoboric acid mixed solution and silicon dioxide obtained after cooling, wash the silicon dioxide, and keep the silicon dioxide for use. After the filtrate and the washing liquid are combined, place in a plastic beaker, then slowly add 58.62 g of 30% potassium hydroxide and keep stirring. Adjust the pH value of the mother liquor in the plastic beaker to 6, continue to stir and react for 30 minutes until it cools to room temperature; then stop stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com