Iron-Based Catalysts for Direct Synthesis of Light Olefins from Syngas

A technology of iron-based catalysts and low-carbon olefins, applied in the direction of physical/chemical process catalysts, heterogeneous catalyst chemical elements, metal/metal oxides/metal hydroxide catalysts, etc., can solve the problem of low selectivity of low-carbon olefins, Low CO conversion rate and other issues, to achieve the effect of improving selectivity, large specific surface area, and rich pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

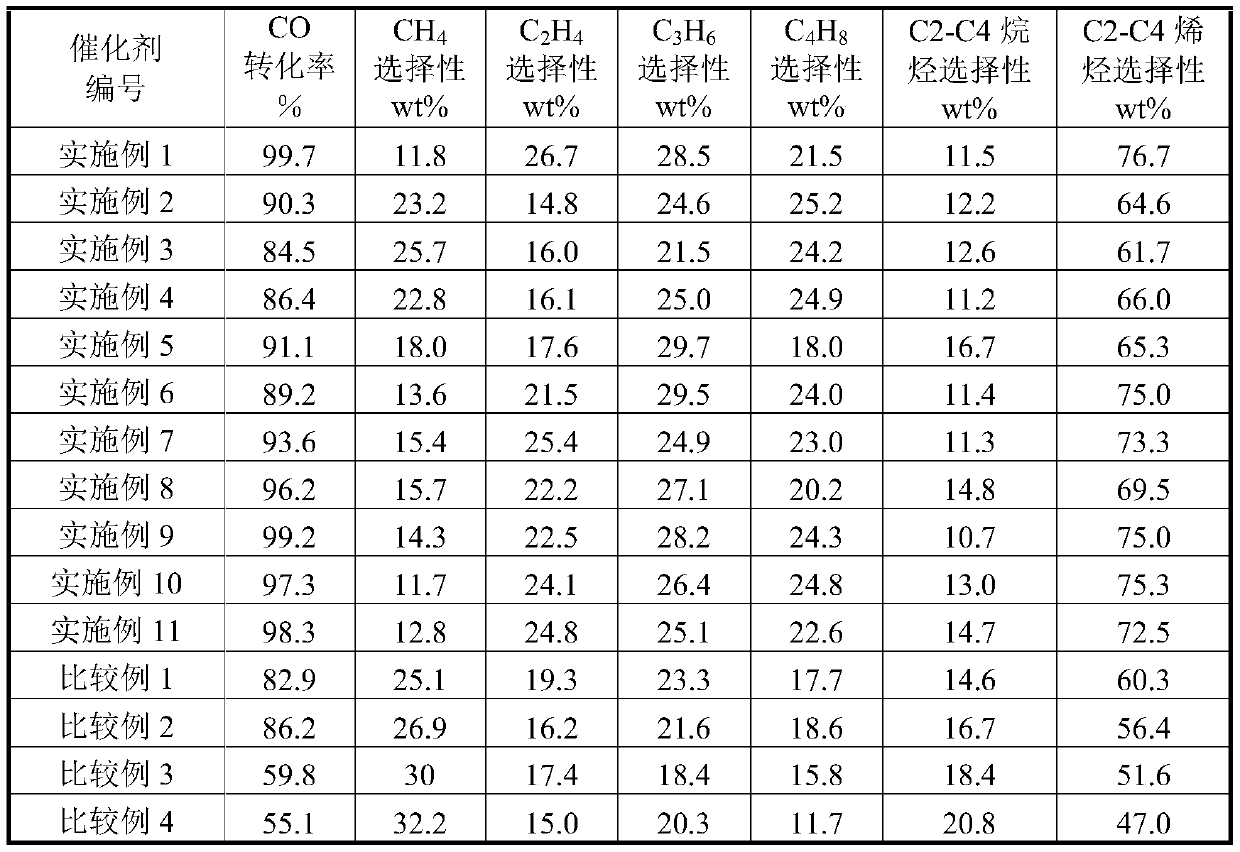

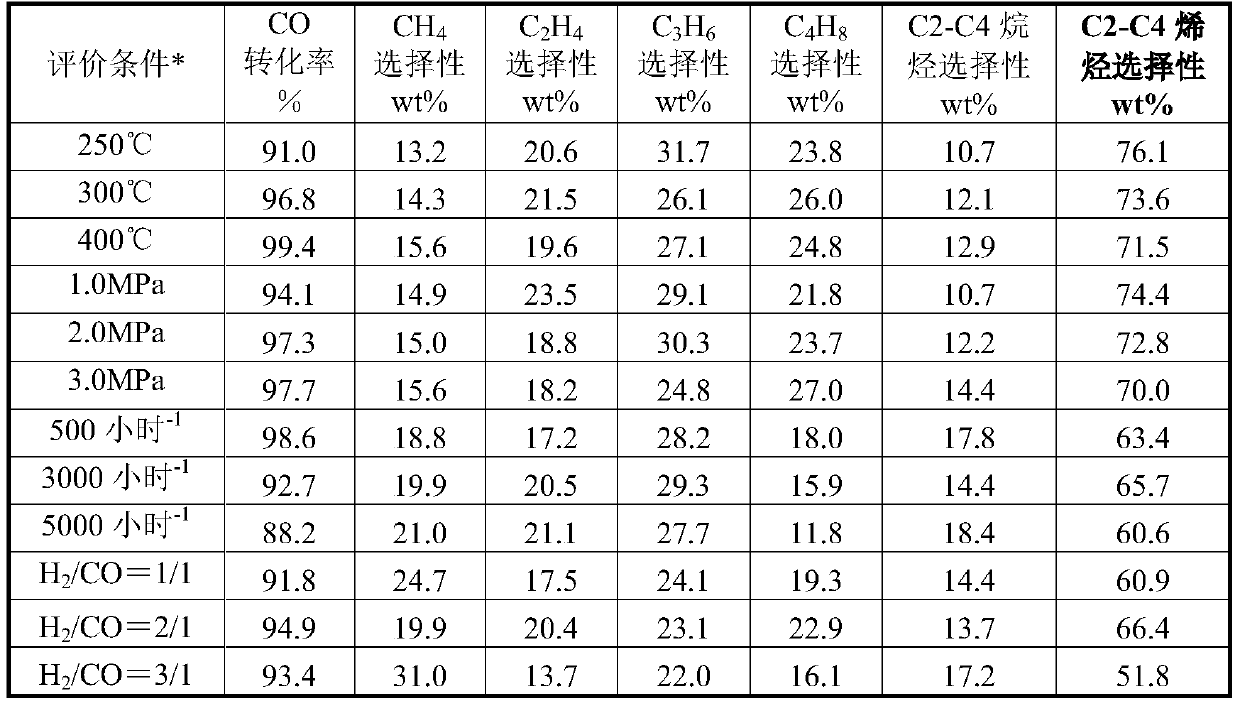

Examples

Embodiment 1

[0043] Weigh 30.0 grams of ferric oxide (Fe 2 o 3 ), 15.0 grams of manganese dioxide (MnO 2 ), 15.0 grams of magnesium oxide (MgO), 34.0 grams of α-alumina (α-Al 2 o 3 ), 3.0 grams of niobium pentoxide (Nb 2 o 5 ) and 3.0 grams of tantalum pentoxide (Ta 2 o 5 ) six kinds of raw materials and 4 grams of hydroxypropyl methylcellulose powder of 4% by weight according to the total amount of raw materials, milled and mixed for 4 hours in a ball mill; gram into the ground and mixed material, and knead until soft; the kneaded material is sent into the extruder, made into a strip with a diameter of 5mm, and cut into a column with a length of 20mm, and after natural drying, Send it to the drying equipment and dry it at 120°C for 8 hours for later use; put the dried precursor into a high-temperature furnace and calcinate it at 1600°C for 5.0 hours, and after cooling, crush and sieve it into 60-80 meshes to obtain the desired compound Fe-based catalysts for direct synthesis of li...

Embodiment 2

[0045] Weigh 50.0 grams of ferric oxide (Fe 2 o 3 ), 10.0 grams of manganese dioxide (MnO 2 ), 10.0 grams of magnesium oxide (MgO), 28.0 grams of α-alumina (α-Al 2 o 3 ), 1.0 g niobium pentoxide (Nb 2 o 5 ) and 1.0 g of tantalum pentoxide (Ta 2 o 5 ) six kinds of raw materials and 2 grams of hydroxypropyl methylcellulose powder with a percentage by weight of 2% by the total amount of raw materials, milled and mixed for 4 hours in a ball mill; gram into the ground and mixed material, and knead until soft; the kneaded material is sent into the extruder, made into a strip with a diameter of 5mm, and cut into a column with a length of 20mm, and after natural drying, Send it to the drying equipment and dry it at 120°C for 8 hours for later use; put the dried precursor into a high-temperature furnace and calcinate it at 1600°C for 5.0 hours, and after cooling, crush and sieve it into 60-80 meshes to obtain the desired compound Fe-based catalysts for direct synthesis of light...

Embodiment 3

[0047] Weigh 20.0 grams of ferric oxide (Fe 2 o 3 ), 25.0 grams of manganese dioxide (MnO 2 ), 25.0 grams of magnesium oxide (MgO), 20.0 grams of α-alumina (α-Al 2 o 3 ), 5.0 grams of niobium pentoxide (Nb 2 o 5 ) and 5.0 grams of tantalum pentoxide (Ta 2 o 5 ) six kinds of raw materials and 6 grams of hydroxypropyl methylcellulose powder of 6% by weight in the total amount of raw materials, milled and mixed for 4 hours in a ball mill; gram into the ground and mixed material, and knead until soft; the kneaded material is sent into the extruder, made into a strip with a diameter of 5mm, and cut into a column with a length of 20mm, and after natural drying, Send it to the drying equipment and dry it at 120°C for 8 hours for later use; put the dried precursor into a high-temperature furnace and calcinate it at 1600°C for 5.0 hours, and after cooling, crush and sieve it into 60-80 meshes to obtain the desired compound Fe-based catalysts for direct synthesis of light olefin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com