Preparation method of n-butylamine

A production method and a technology for n-butylamine, which are applied in the field of preparation of n-butylamine, can solve the problems of good product sales, equipment shutdown, product slowdown, etc., and achieve the effects of preventing slowdown, high production efficiency, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

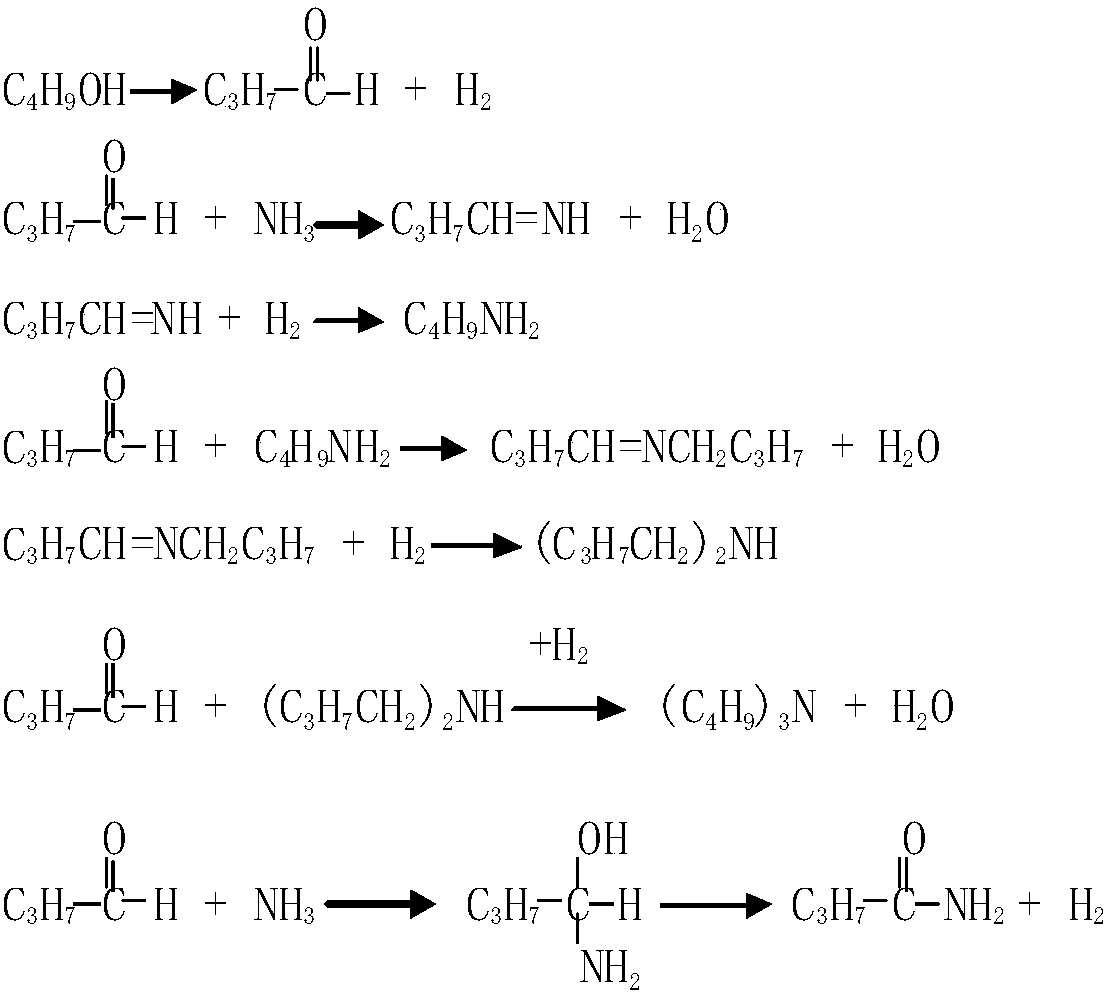

Method used

Image

Examples

Embodiment 1

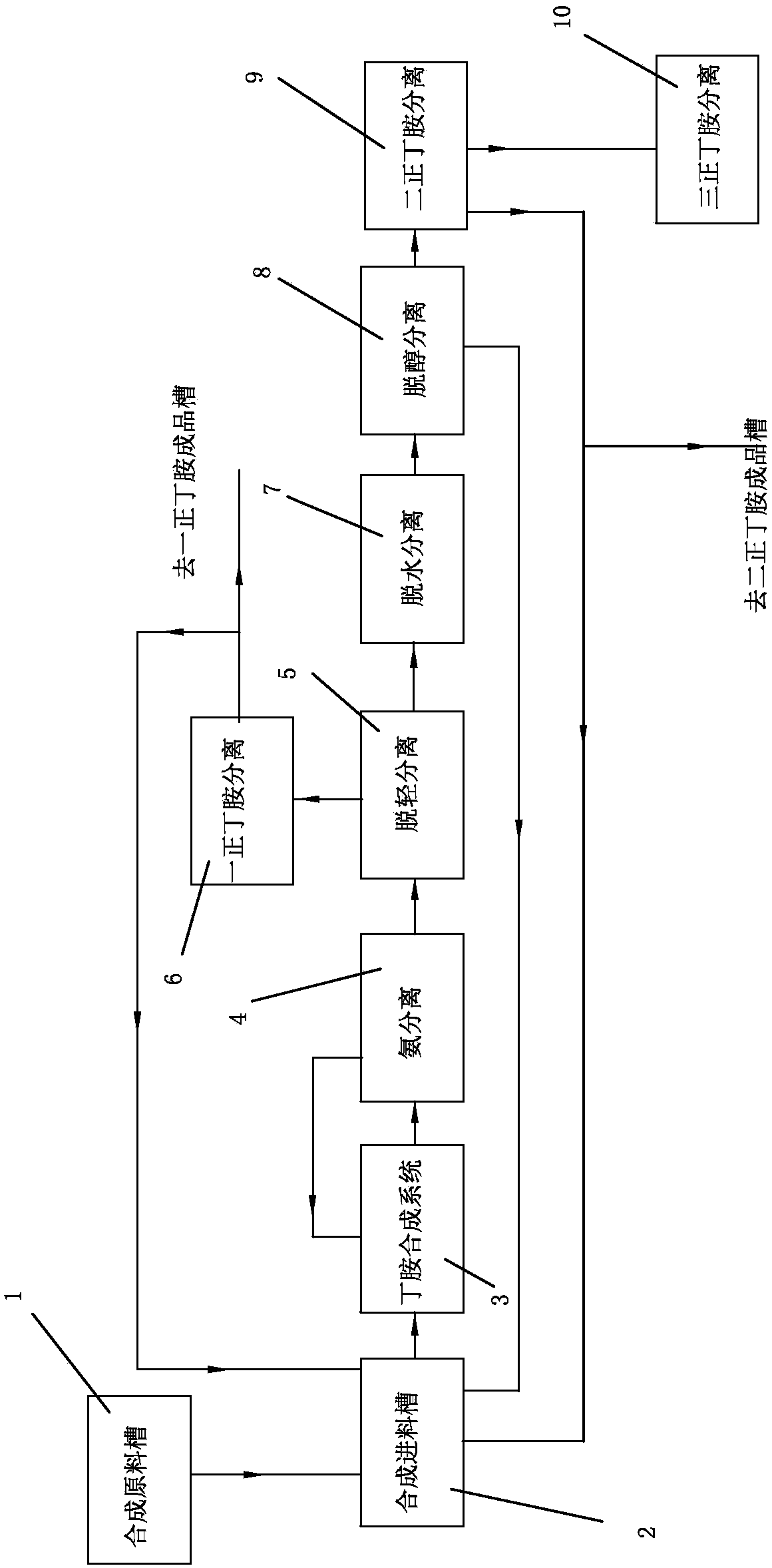

[0028] Embodiment 1: control-n-butylamine product output

[0029] Prepare a certain proportion of n-butanol and liquid ammonia reaction materials, control the ratio of n-butanol and liquid ammonia in the reaction materials (ammonia content is controlled at 5-10%), the reaction materials are vaporized after being preheated by the preheater, and the reaction materials are Put it into the reactor, the hot spot temperature difference of the reactor is 15-25°C, the reaction pressure is 0.6-1.3MPa, the hydrogen concentration is controlled at 21-29%, and the synthesis reaction occurs in the presence of hydrogen, and it is separated after deamination and dehydrogenation A n-butylamine product is produced, and a n-butylamine product is added to the reaction material to carry out a feed-back synthesis reaction, and the remaining product is collected after dehydration and dealcoholization, and the product of the feed-back synthesis reaction is subjected to deamination, dehydrogenation, de...

Embodiment 2

[0031] Embodiment 2: control the output of di-n-butylamine product

[0032] Prepare a certain proportion of n-butanol and liquid ammonia reaction materials, control the ratio of n-butanol and liquid ammonia in the reaction materials, and vaporize the reaction materials after being preheated by the preheater, and put the reaction materials into the reactor. The reaction temperature of the reactor is The temperature is 6-13°C, the reaction pressure is 0.6-1.3MPa, the hydrogen concentration is controlled at 31-39%, and the synthesis reaction occurs in the presence of hydrogen, and di-n-butylamine is separated after deamination, dehydrogenation, dehydration and dealcoholization , the di-n-butylamine product is added to the reaction material to carry out the feed synthesis reaction, and the remaining product is collected. The product of the feed synthesis reaction is collected after deamination, dehydrogenation, dehydration and dealcoholization, and a normal Butylamine, tri-n-butyl...

Embodiment 3

[0035] The reaction pressure in embodiment 1 and embodiment 2 is changed into 0.6-1.3MPa by original 1.3-1.5MPa, and all the other steps are unchanged, and after pressure drops, tri-n-butylamine product output ratio increases, and the transformation rate of material is basically There is no decline, the device consumption is significantly reduced, and the steam consumption of the ammonia tower is greatly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com